Technological method for sealing operation of middle-deep U-shaped butted geothermal well casing pipeline

A process method and geothermal well technology, applied in sealing/isolation, drilling equipment and methods, drilling equipment, etc., can solve problems such as environmental damage, groundwater needs to be recharged, and no water in areas rich in geothermal resources, so as to achieve safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

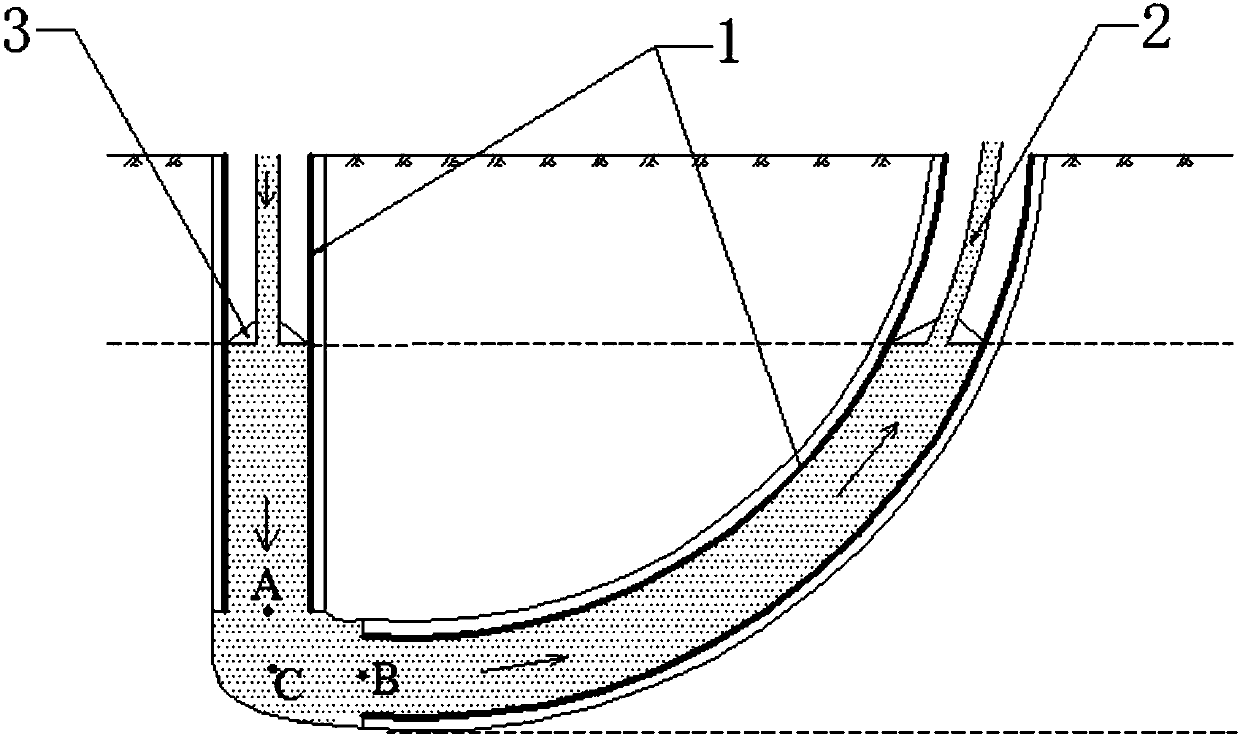

Embodiment 1

[0043] The formation in the butt joint interval is stable and complete without pores, fissures, or karst caves; the construction is carried out using the circulation type of open hole channel, and the construction method is as follows: Drill the vertical well to the predetermined depth A, and run the production casings 1 to A in the vertical well At point C, use a small-diameter core drilling smaller than the inner diameter of production casing 1, continue to drill down 5-6mm to reach point C, then clean the wellbore with a large amount of pump, and drill the butt well to the predetermined depth B by using precise directional drilling method Point, run the production casing 1 to point B in the docking well, adopt a small diameter core drilling smaller than the inner diameter of the production casing 1, and communicate with the slim hole of the vertical well;

[0044] Through the circulation of slurry, there is no sediment at the bottom of the well and in the wellbore; then a pr...

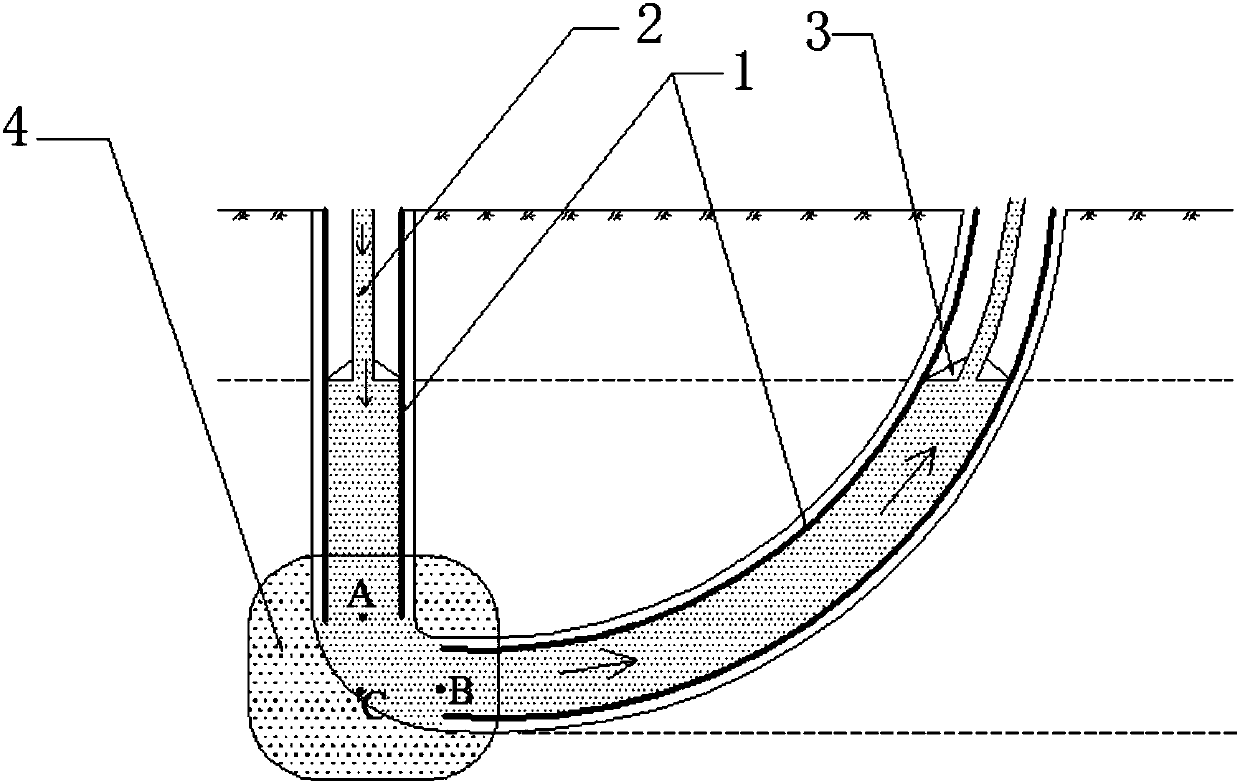

Embodiment 2

[0050] The stratum in the butt joint layer is stable and has poor integrity, and there are pores, cracks and caves; the cement body wellbore channel type circulation type is used for construction, and the construction method is as follows: Drill the vertical well to the predetermined depth C, and use the hydraulic method to create the cavity , the cavity diameter is 10m, and the cavity height is 12m. Cement is injected to form cement body 4. After the cement body 4 solidifies for 24 hours, use a high-pressure gun to flush to point A, flush into the cement body 4, and run the production casing in the vertical well. From point 1 to point A, use small-diameter core drilling smaller than the inner diameter of production casing 1, continue to drill down 5-6mm to reach point C, then clean the wellbore with a large amount of pumping, and use precise directional drilling to drill the butt well to Predetermined depth point B, enter the cement body, run production casing 1 to point B in ...

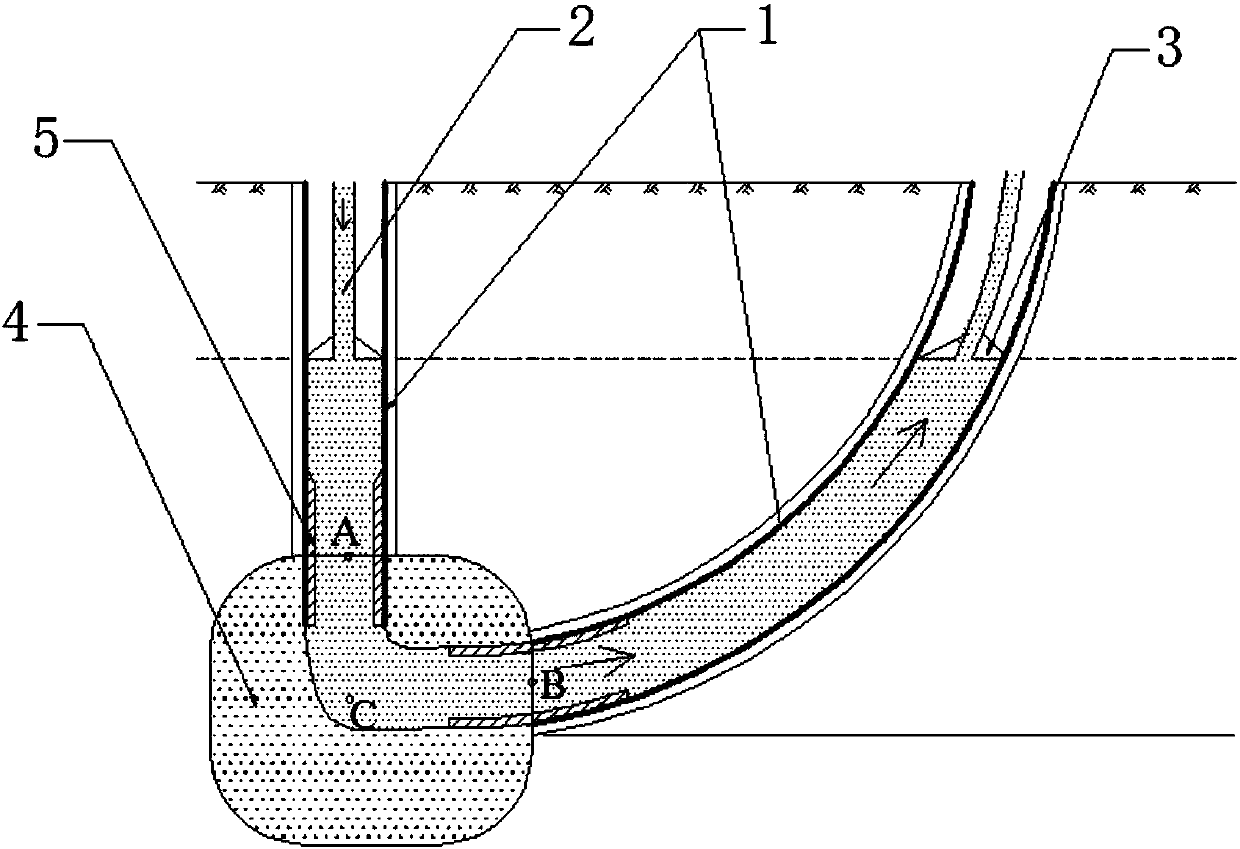

Embodiment 3

[0058] The strata in the butt joint layer are stable and have poor integrity, and there are many pores, fissures, and karst caves. Mechanical and hydraulic methods cannot be used to form larger chambers; the construction is carried out using the circulation type of cement liner wellbore channel type, and the construction method is as follows: vertical well drilling Go to the predetermined depth point C, use the hydraulic method to build the cavity, the final cavity diameter is ≥ 4m, the cavity height is < 10m, inject cement to form the cement body 4, and after the cement body 4 is solidified for 24 hours, use a high-pressure gun to flush to point A and flush Enter the cement body 4, after the cement body is solidified for 72 hours, run the production casing 1 to point A in the vertical well, use a small diameter smaller than the inner diameter of the production casing 1 for core drilling, and continue to drill down 5-6mm to reach point C, Then the wellbore is cleared with a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com