In-vehicle active noise reduction system

An active noise reduction, automotive technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of immature commercial products and unsatisfactory low-frequency sound, and achieve the effect of simple connection and layout, convenient implementation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

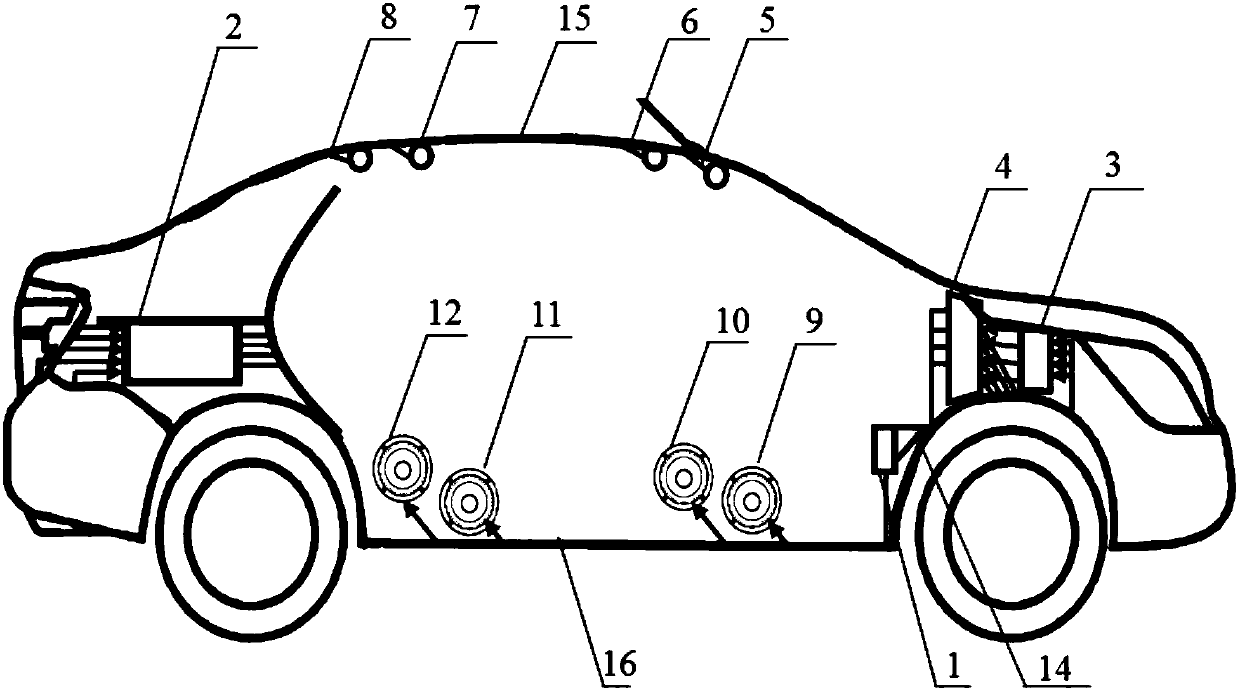

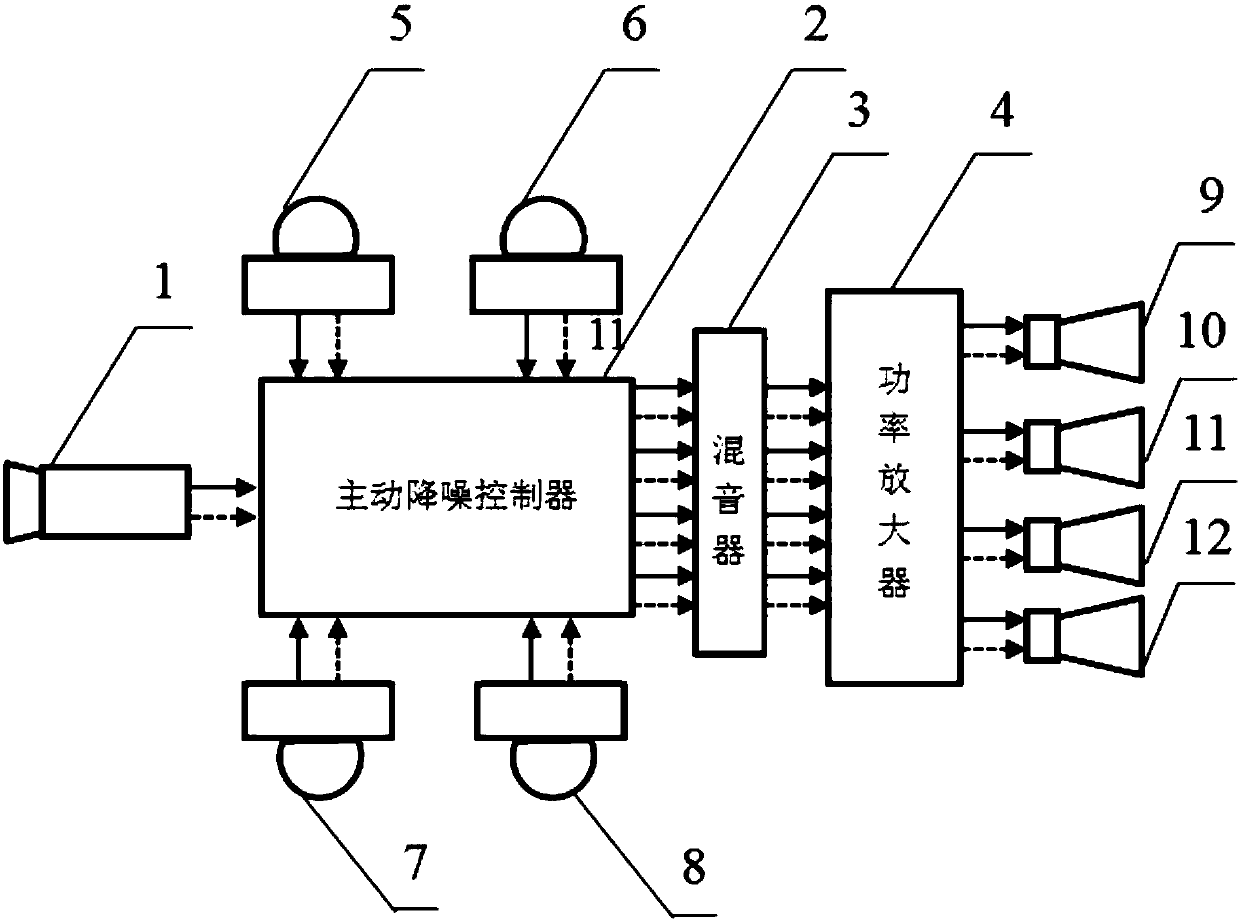

[0023] Such as figure 1 , figure 2 As shown, the present invention provides an active noise reduction system in a vehicle, the main feature of which is its connection and arrangement;

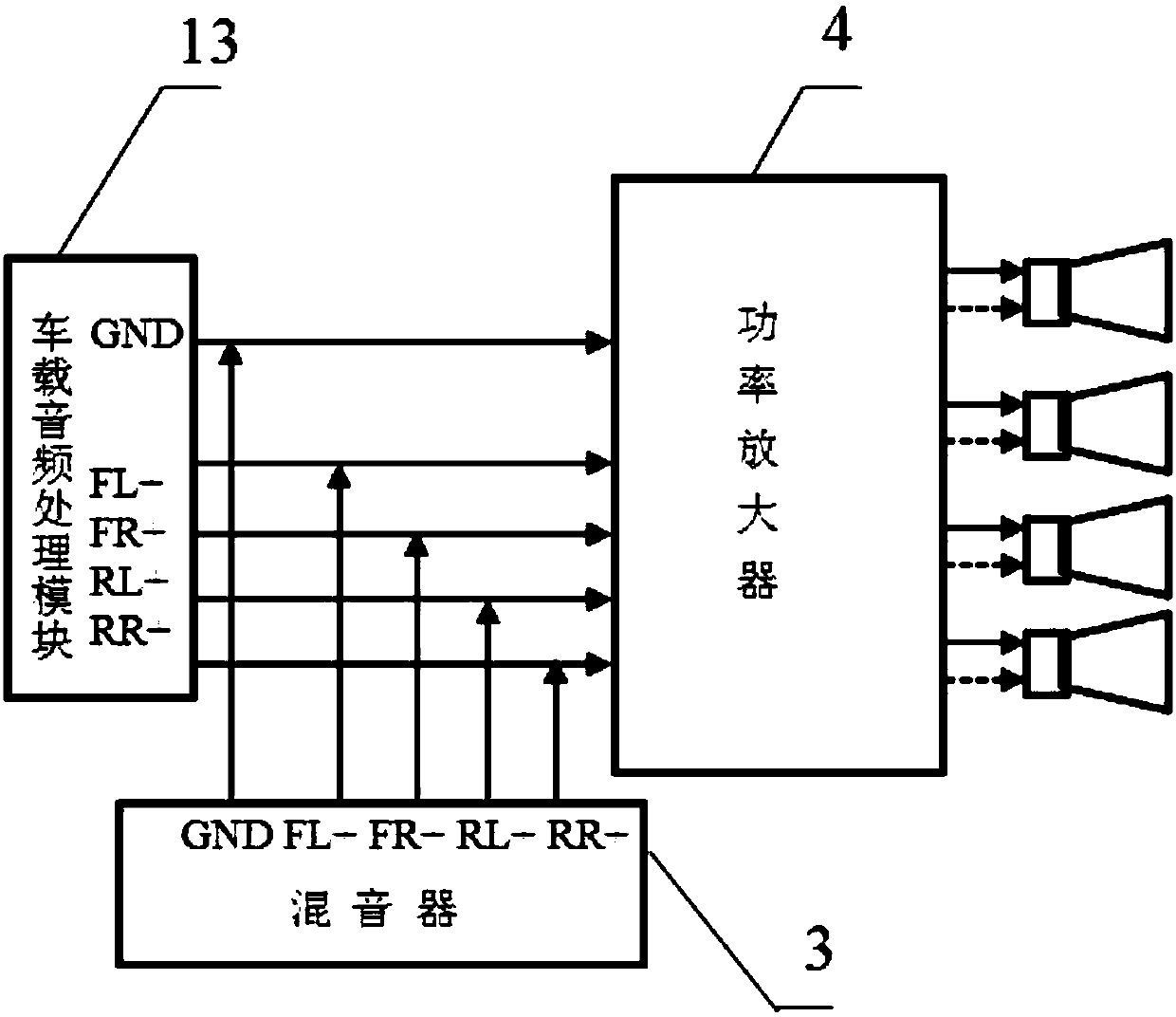

[0024] The system includes: speed sensor 1, active noise reduction controller 2, sound mixer 3, power amplifier 4 error microphones 5, 6, 7, 8, car speakers 9, 10, 11, 12, car audio processing module 13, car CAN interface 14, ceiling wiring 15 and carpet wiring 16;

[0025] Among them, the power amplifier 4, the car audio processing module 13, the car CAN interface 14, and the car speakers 9, 10, 11, and 12 are the original car equipment of the car, and the rest are external devices used by the active noise reduction system in the car;

[0026] The speed sensor 1 is connected to the CAN interface 14 of the car, and is connected to the active noise reduction controller 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com