Full-automatic winder for cell core of lithium cell

A technology of lithium batteries and cell rolls, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as increased product defect rate, increased pole piece damage rate, and reduced equipment reliability, achieving low defective rate, Save labor costs, the effect of high cell uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

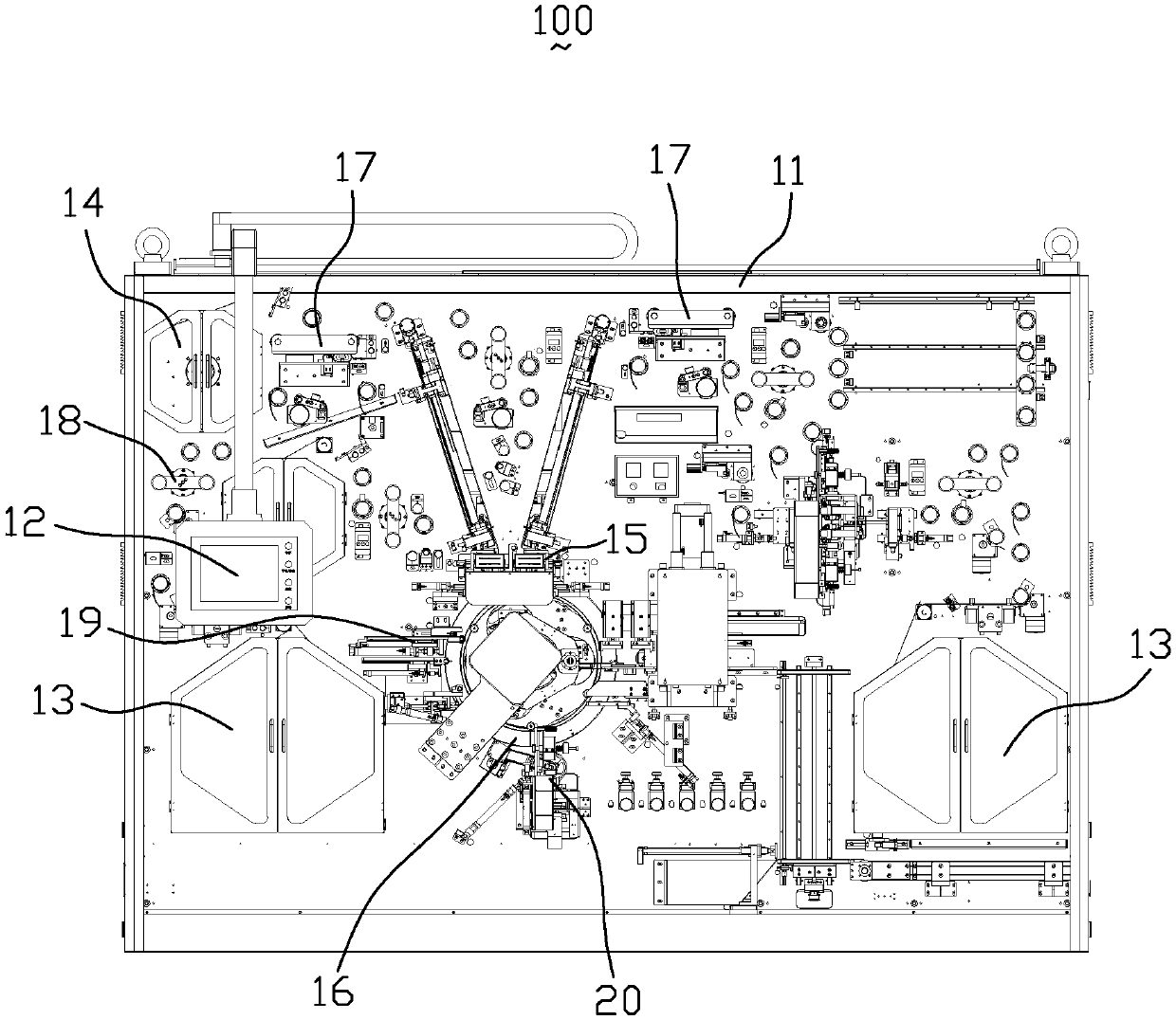

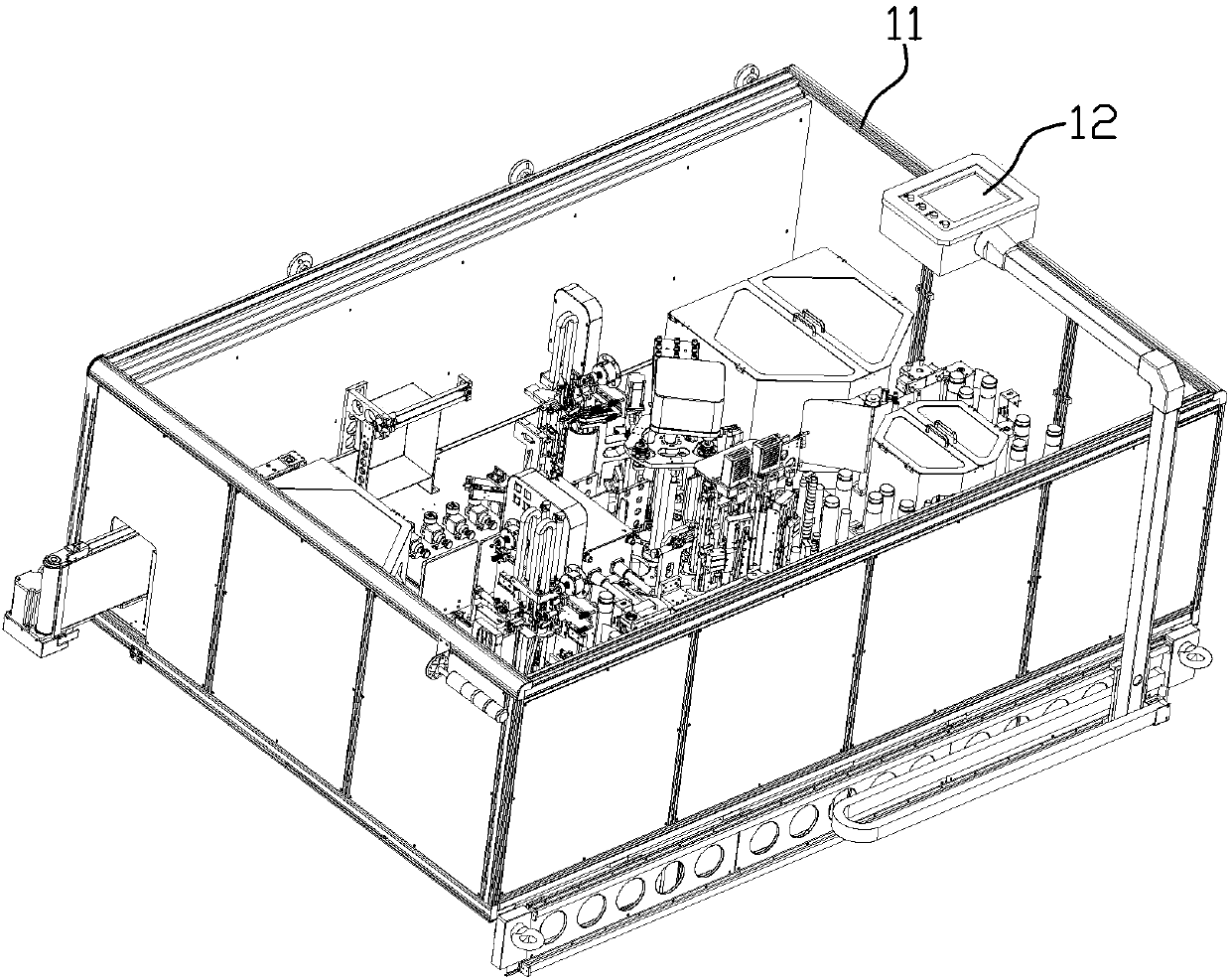

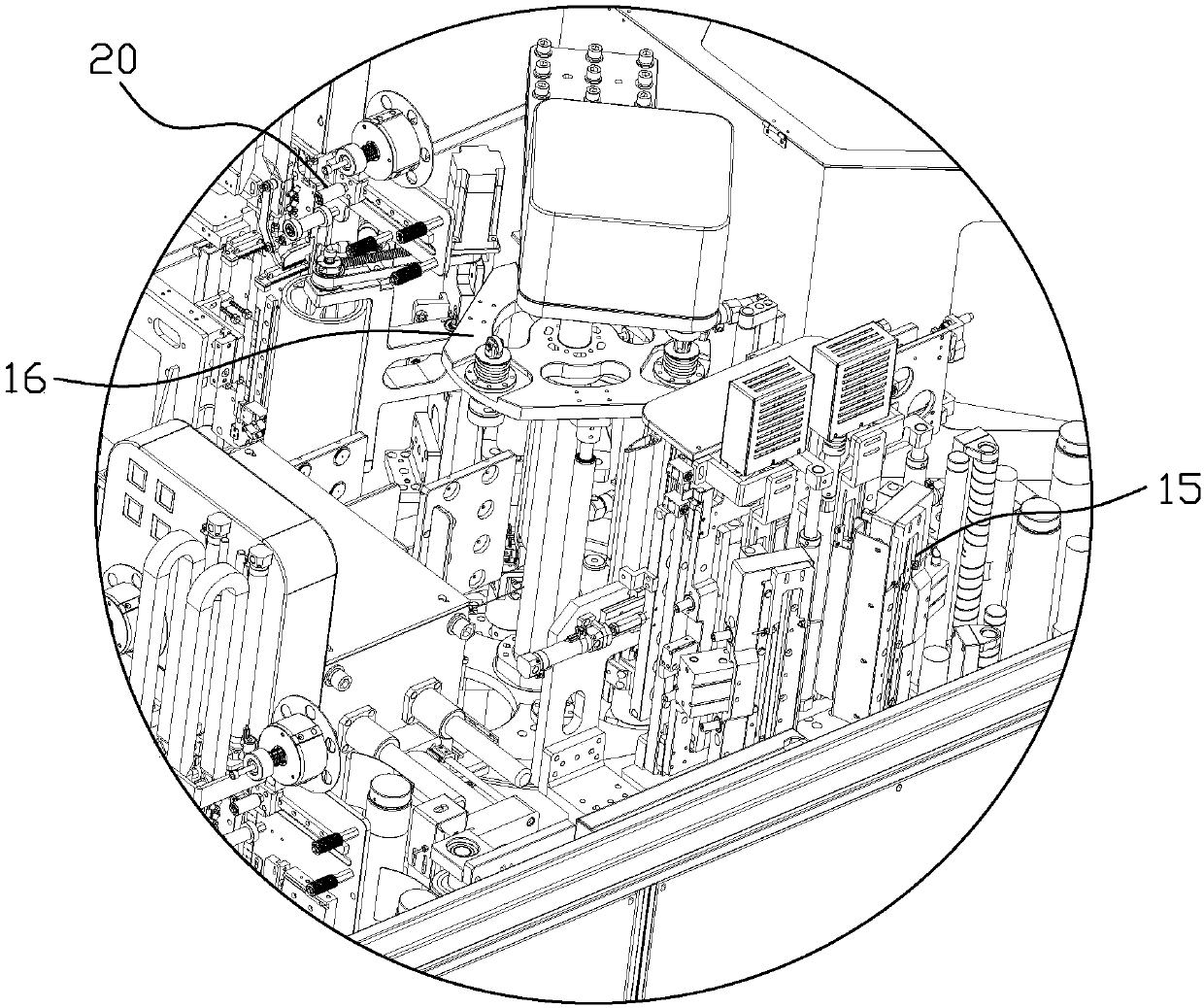

[0033] figure 1 It is a structural schematic diagram of the fully automatic lithium battery cell winding machine of the present invention. figure 2 It is a schematic diagram of another perspective of the fully automatic lithium battery cell winding machine of the present invention. image 3 It is a partial structural schematic diagram of the fully automatic lithium battery cell winding machine of the present invention. see Figure 1 to Figure 3 , a fully automatic lithium battery cell winding machine 100, including a chassis 11, and a control mechanism 12 arranged at the top left end of the chassis 11, the fully automatic lithium battery ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap