Method and device for producing large-volume containers with a flange by plastic blow molding

A high-volume, flanged technology for home appliances, other home appliances, applications, etc., that can solve problems such as high transportation and handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

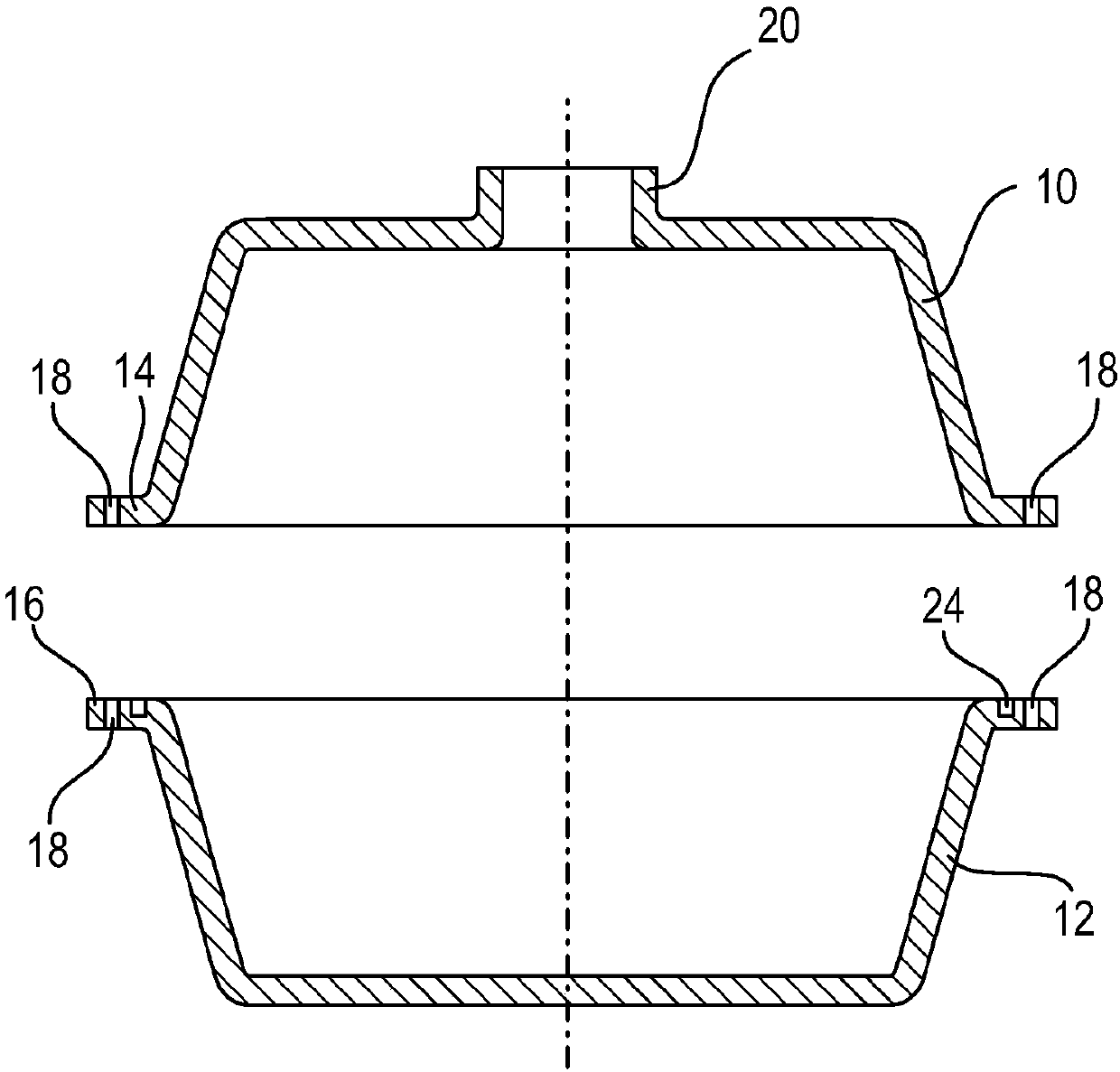

[0025] figure 1 The open container housings 10 , 12 produced in a blow molding machine are shown in section, each having a circumferential flange 14 , 16 . Through holes 18 are formed in the flanges 14 , 16 , respectively, and a circumferential groove 24 is formed in the flange 16 . The container housings 10 , 12 are transported in the open state from the place of production to the point of destination, where they are connected to each other along flanges 14 , 16 in a liquid-tight manner by screw connections. The large-volume closed containers formed in this way are used at the destination as potable water tanks, waste water tanks, waste containers, rainwater receiving tanks, fire-fighting water tanks and the like. In the upper container case 10, an inlet 20 is formed.

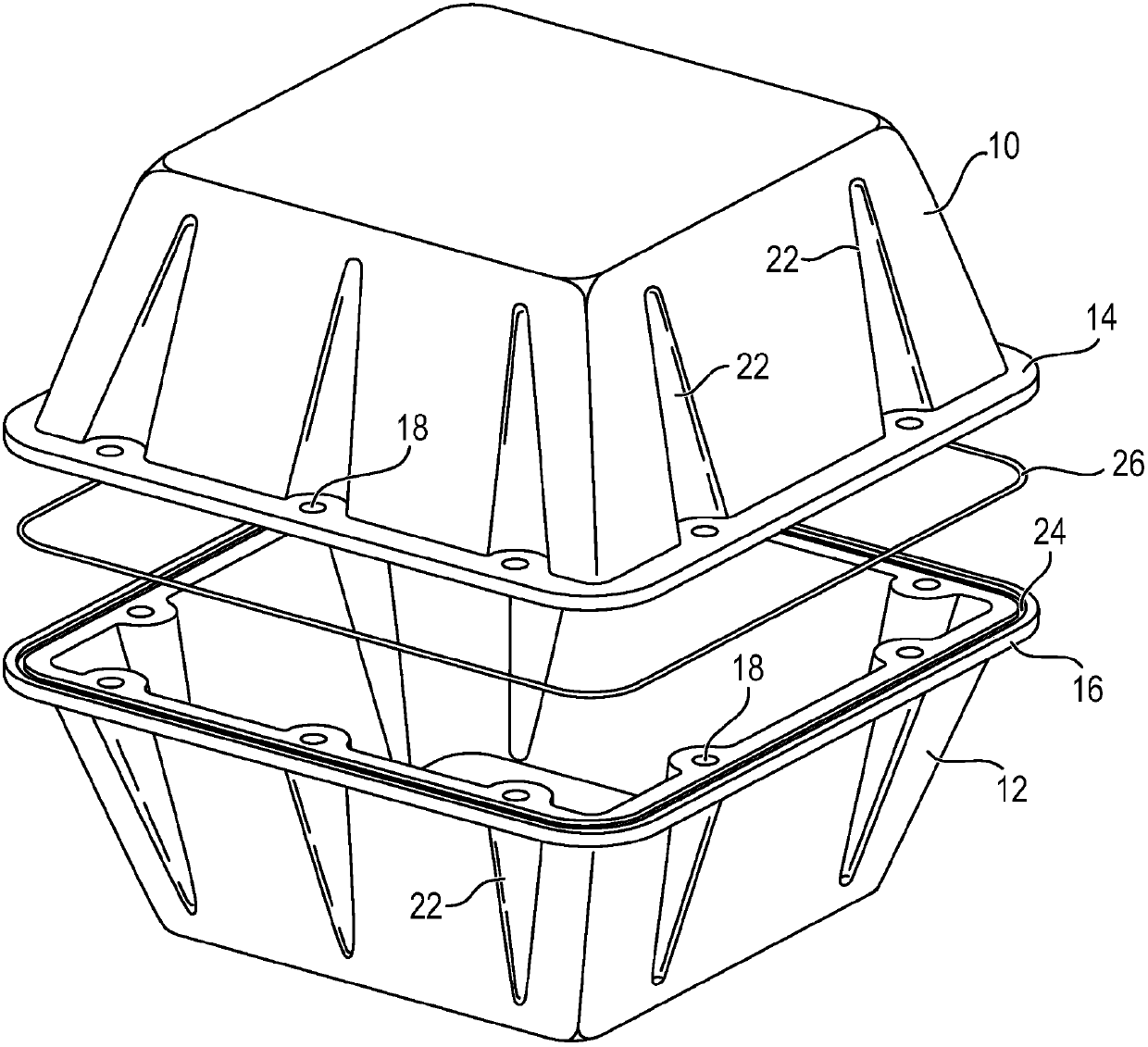

[0026] figure 2 A perspective view of the container shells 10 , 12 is shown, each having a reinforcement 22 . The flange 16 comprises a circumferential groove 24 into which a seal 26 for the liquid-tight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com