Preparation method of high-tenacity edible vegetable sheets

A vegetable paper, high-toughness technology, which is used in the preservation of fruits/vegetables with sugar, preservation of fruits and vegetables, sustainable manufacturing/processing, etc. It can solve the problems of shortened storage time, increased storage difficulty, poor waterproofness, etc., and achieves rich nutrition. Ingredient, avoid moisture deterioration, excellent toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

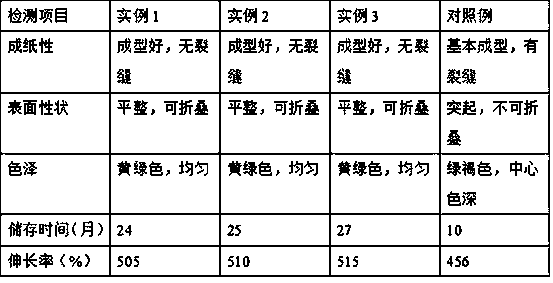

Examples

example 1

[0028] Weigh the head lettuce and put it into a tissue grinder to crush for 20 minutes to obtain the lettuce fragments, rinse them with clean water for 3 times and take them out, then mix the washed lettuce fragments and 0.5% sodium bicarbonate solution according to the mass ratio of After mixing at a ratio of 1:10, heat up to 70°C, blanching for 3 minutes to obtain pretreated head lettuce; weigh the mangoes, wash them, peel them, cut off the pulp, put them in a mortar, grind them, and obtain crushed products. Mix with clear water at a mass ratio of 1:8, stir and wash for 22 minutes, filter and separate with gauze after washing, collect the filtrate, and the obtained filter residue is mango fiber silk; the pretreated head lettuce and the filtrate are 3:1 in mass ratio After mixing, put it into a fermenter, add yeast powder with 1% mass of pretreated head lettuce and sterile water with 3 times the mass of pretreated head lettuce to the fermenter, stir evenly and seal and ferment...

example 2

[0030] Weigh the head lettuce and put it into a tissue grinder to pulverize for 25 minutes to obtain the lettuce fragments, rinse them with clear water 4 times and take them out, and then the lettuce fragments after washing and the sodium bicarbonate solution with a mass fraction of 0.5% are After mixing at a ratio of 1:10, heat up to 75°C, blanching for 4 minutes to obtain pretreated head lettuce; weigh the mango, wash it, peel it, cut off the pulp, put it in a mortar, grind it, and get the crushed product. Mix with clear water at a mass ratio of 1:8, stir and wash for 26 minutes, filter and separate with gauze after washing, collect the filtrate, and the obtained filter residue is mango fiber silk; the pretreated head lettuce and the filtrate are 3:1 in mass ratio After mixing, put it into a fermenter, add yeast powder with 1% mass of pretreated head lettuce and sterile water with 4 times the mass of pretreated head lettuce to the fermenter, stir evenly and seal and ferment a...

example 3

[0032] Weigh the head lettuce and put it into a tissue grinder to pulverize for 30 minutes to obtain the lettuce fragments, rinse them with clear water for 5 times and take them out, then the washed lettuce fragments and 0.5% sodium bicarbonate solution with a mass fraction of After mixing at a ratio of 1:10, heat up to 80°C, blanching for 5 minutes to obtain pretreated head lettuce; weigh the mango, wash it, peel it, cut off the pulp, put it in a mortar, grind it, and get the crushed product. Mix with clear water at a mass ratio of 1:8, then stir and wash for 30 minutes, filter and separate with gauze after washing, collect the filtrate, and the obtained filter residue is mango fiber silk; the pretreated head lettuce and the filtrate are mixed at a mass ratio of 3:1 After mixing, put it into a fermenter, add yeast powder with 1% mass of pretreated head lettuce and sterile water with 5 times the mass of pretreated head lettuce to the fermenter, stir evenly and seal and ferment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com