Tool cathode provided with tool setting device and tool setting method of tool cathode

A tool cathode and tool setting device technology, which is applied in the direction of processing electrodes, accessory devices, manufacturing tools, etc., can solve the problems of affecting the machining accuracy of electrolytic milling and grinding, and the large error of tool setting, so as to eliminate the error of machine tool displacement accuracy and reduce the difficulty of processing and cost, and the effect of improving the accuracy of tool setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific drawings.

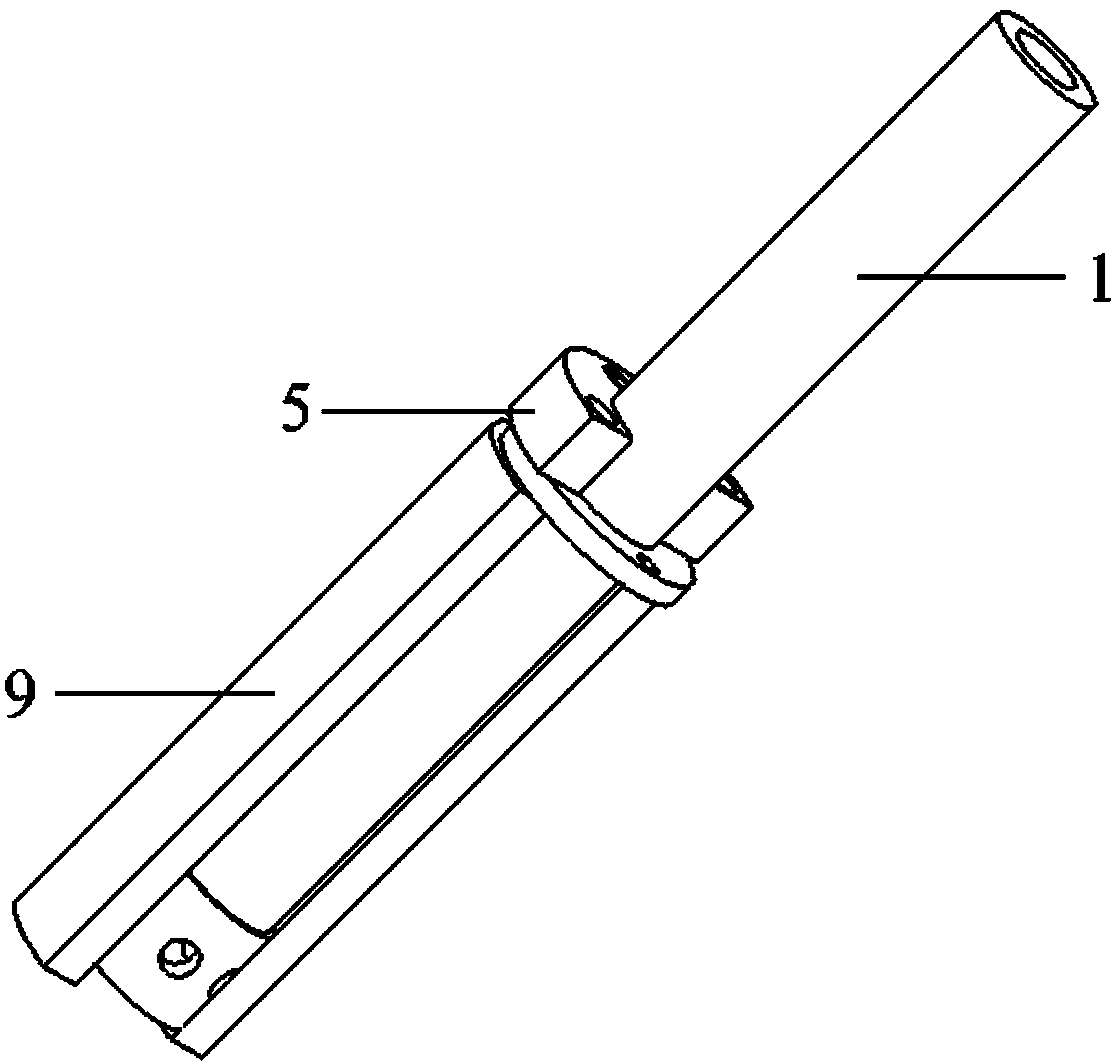

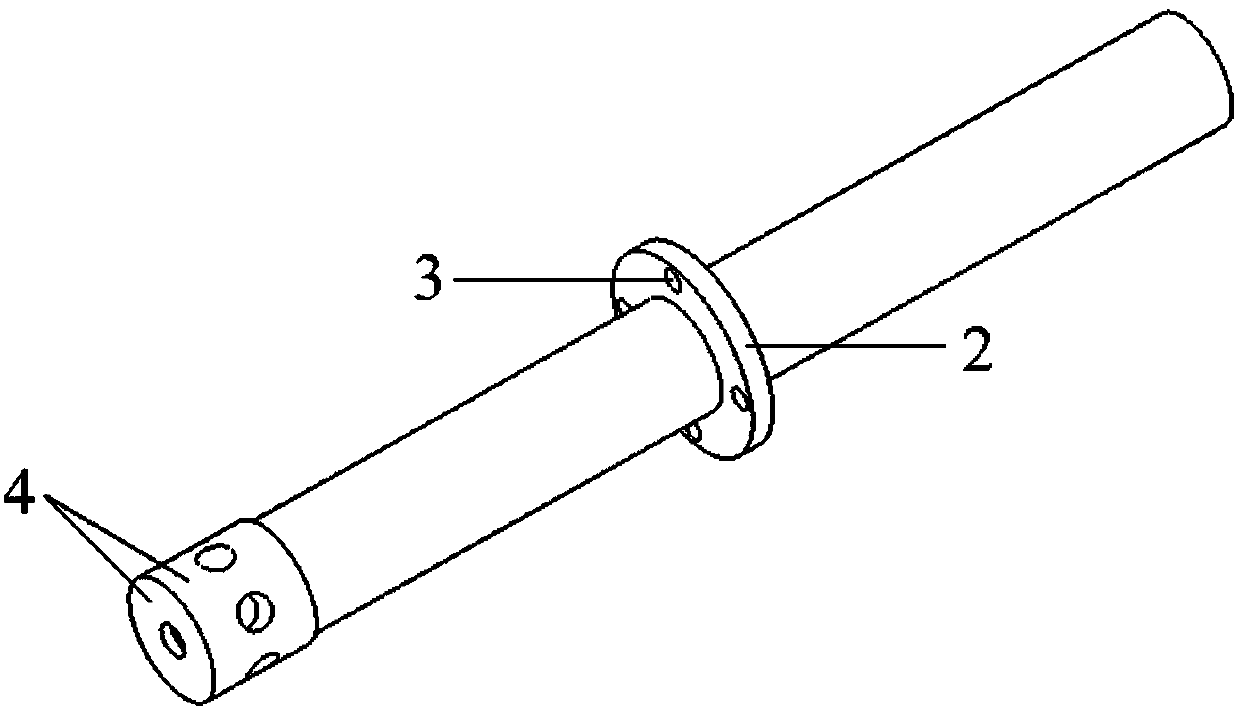

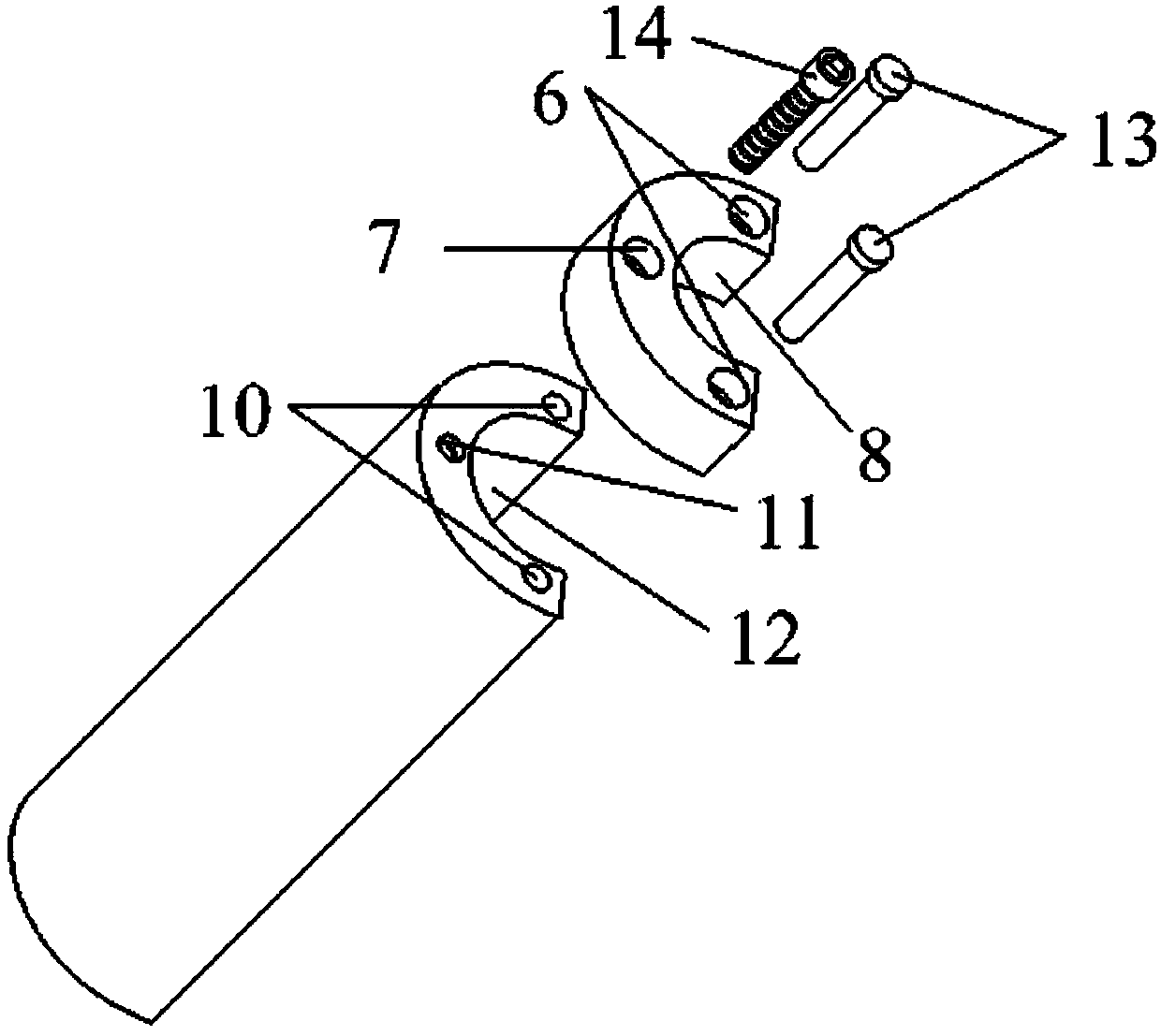

[0023] like Figures 1~3As shown, a detachable tool cathode tool setting device includes a tool cathode 1, a pressing block 5, a tool setting block 9, a positioning polished rod 13 and a tightening screw 14; the tool cathode 1 has a circular flange on the outside of the middle part 2, the circular flange 2 has a flange through hole 3, and the bottom side wall and the bottom end of the tool cathode 1 have an electroplated abrasive grain layer 4 covered by diamond abrasive grains 18; the pressing block 5 is a U-shaped structural block, There is a countersunk head through hole 6 at each end, a countersunk head threaded hole 7 in the middle near the outer side, and a first U-shaped groove 8 on the inner wall; the tool setting block 9 is a U-shaped structural block, and each upper end has a positioning blind Hole 10, there is a threaded hole 11 for the tool setting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com