A small CNC milling and drilling machine and its corrected tool setting method

A technology of CNC milling and drilling machine, which is applied to automatic control devices, other manufacturing equipment/tools, maintenance and safety accessories, etc. The effect of improving tool setting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

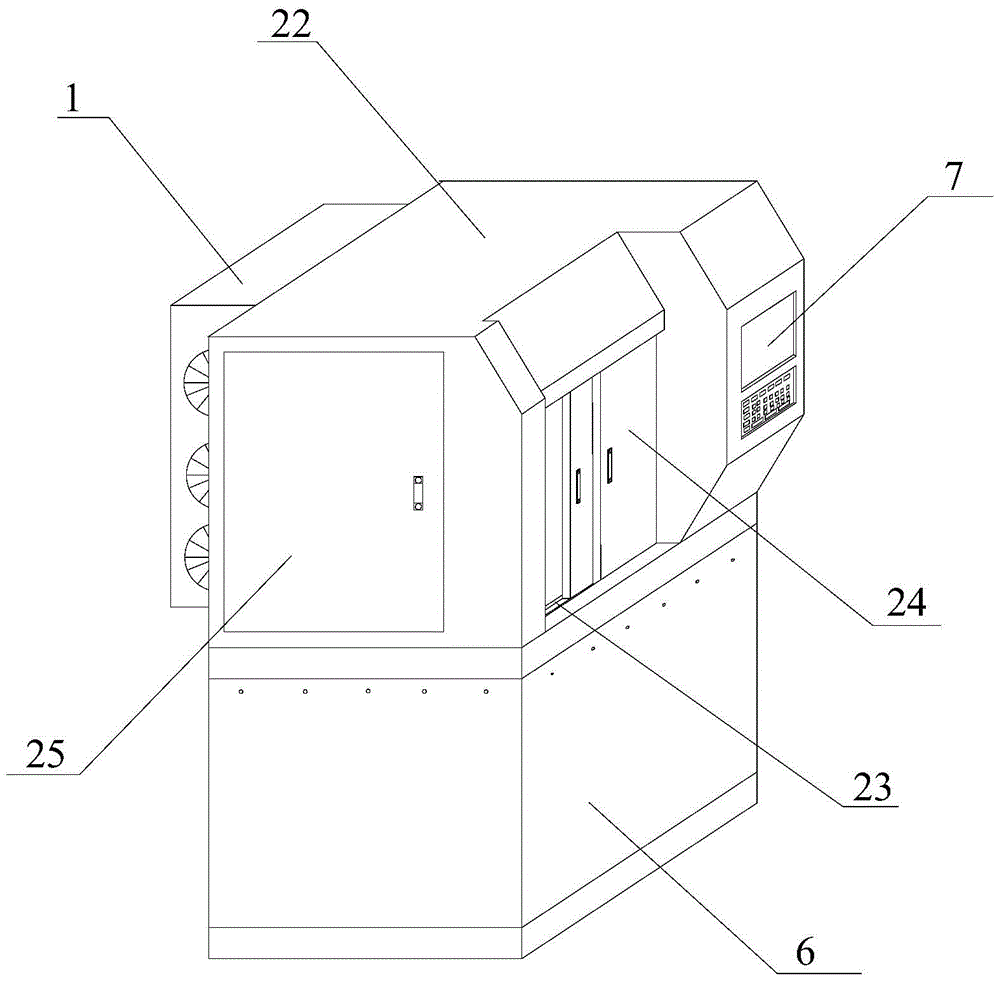

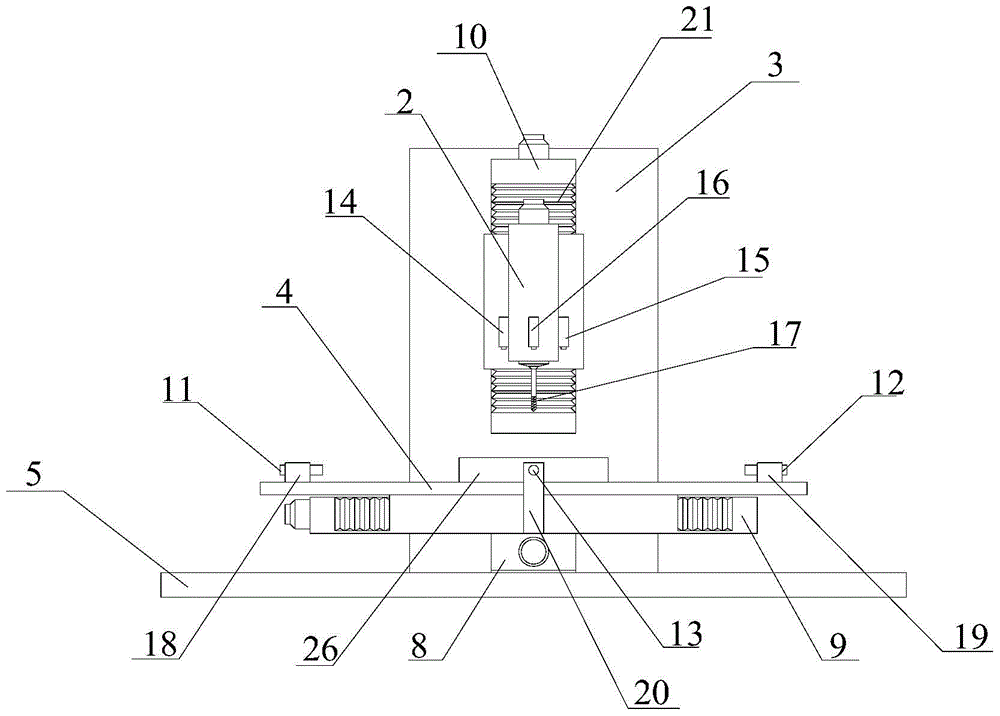

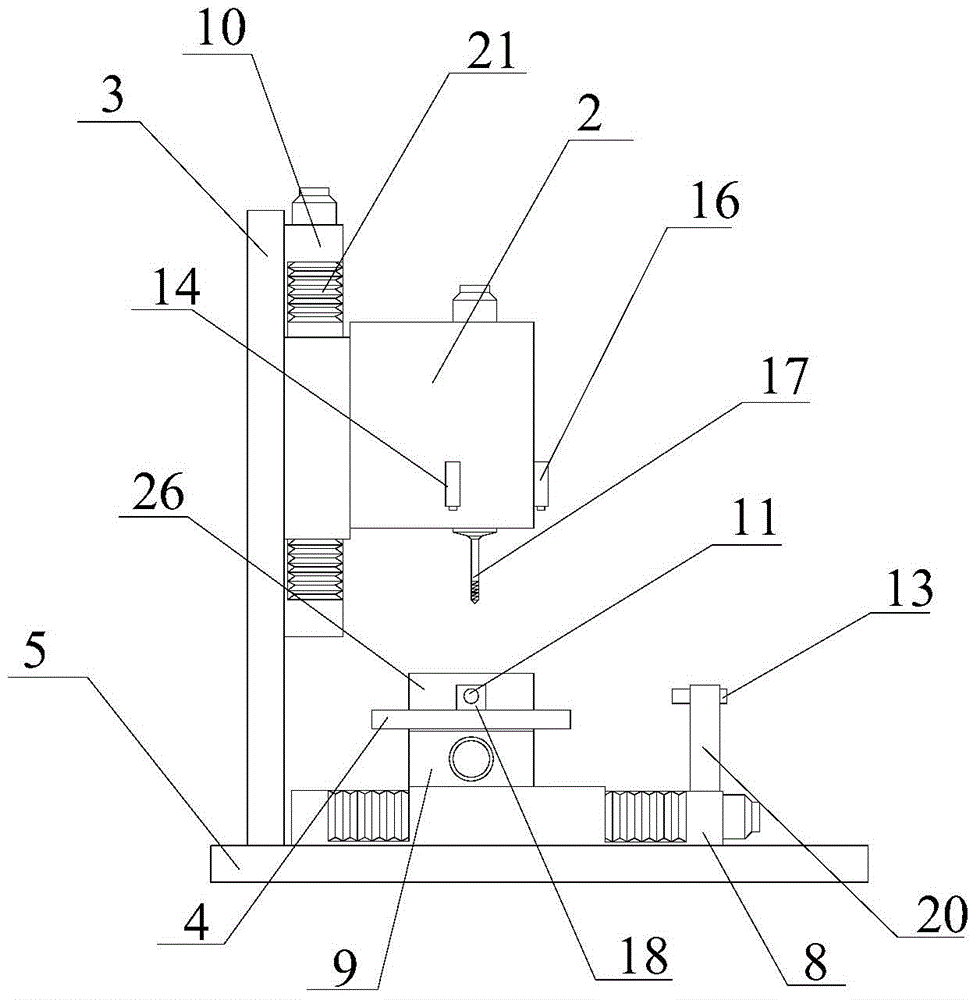

[0029] See attached Figure 1-4 , a small CNC milling and drilling machine of the present invention, comprising a control electric cabinet assembly 1, a drilling and milling head box 2, a column 3, a workbench 4, a base 5, a bottom cabinet assembly 6 and a numerical control computer 7, the workbench 4 The lower part is equipped with an X-direction slide table 8 and a Z-direction slide table 9, and a Y-direction slide table 10 is installed between the drilling and milling head box 2 and the column 3. The CNC milling and drilling machine also includes a correction tool setting device, and the correction Tool checking device comprises the first CCD camera 11, the second CCD camera 12, the 3rd CCD camera 13, the first laser range finder 14, the second laser range finder 15 and the 3rd laser range finder 16, the first The CCD camera 11 and the second CCD camera 12 are symmetrically fixed on the two ends of the Z-direction slide table 9 of the workbench 4 respectively, and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com