Printing equipment and printing method of magnetic printing ink

A magnetic ink and printing equipment technology, applied in the field of printing equipment, can solve the problems of low production efficiency, high cost, and slow production speed, and achieve the effects of high production efficiency, improved production efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

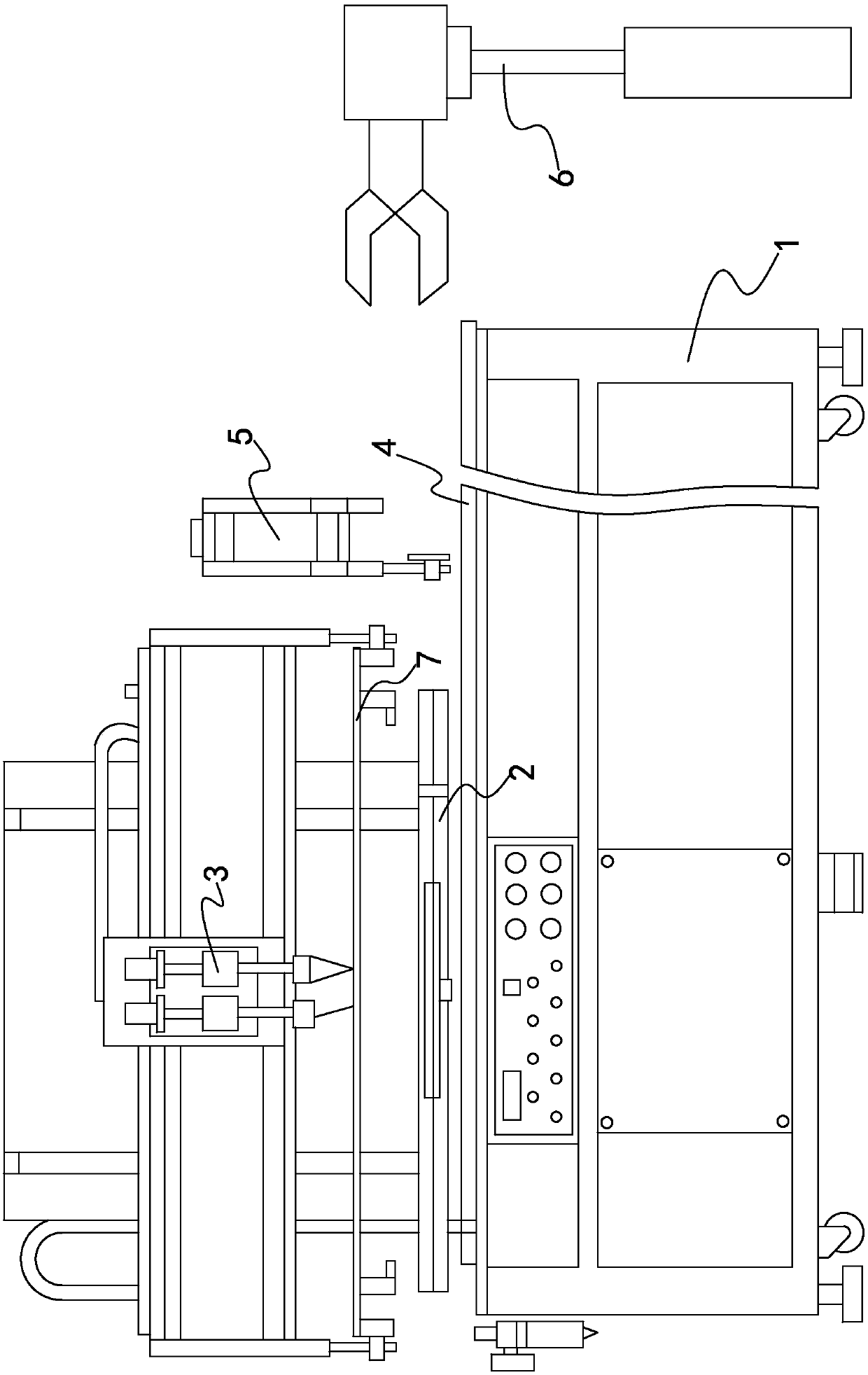

[0034] Such as figure 1 As shown, the printing equipment of this magnetic ink is aimed at sheet printing materials such as paper or sheet film, which is different from coil materials. The printing equipment includes a support 1 on which a slide rail 4 is arranged. A printing platform 2 is slidably arranged on the slide rail 4, and a magnetic mold is arranged in the printing platform 2. An thimble and an air suction device for absorbing printed matter are arranged inside the printing platform 2 . During the operation of the equipment, the thimble can push part or the whole of the printed matter away from the printing platform 2, so that the printed matter can be transferred away from the printing platform 2 conveniently. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap