Supporting load detecting device for winch and detecting method of supporting load detecting device

A technology of load testing and winch, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as large safety hazards, large test site space, and different supporting loads, so as to eliminate unsafe conditions. Hidden dangers, cost and time savings, and the effect of reducing the test site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

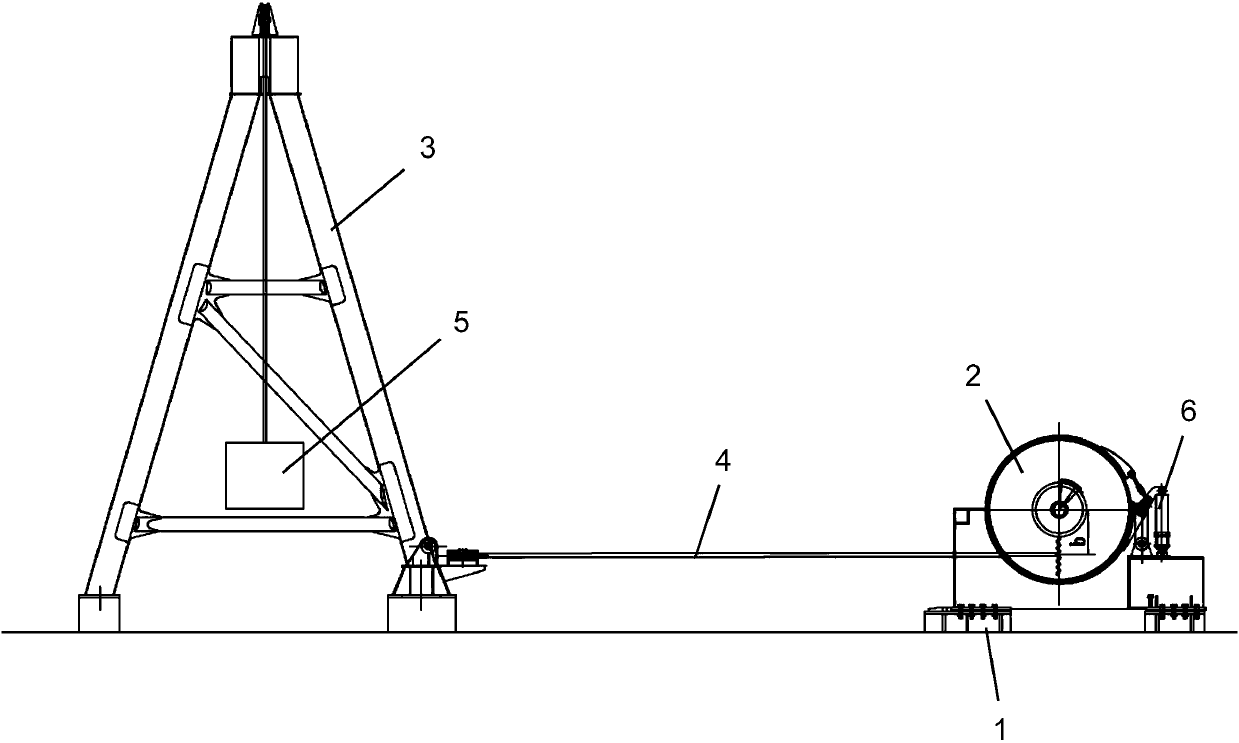

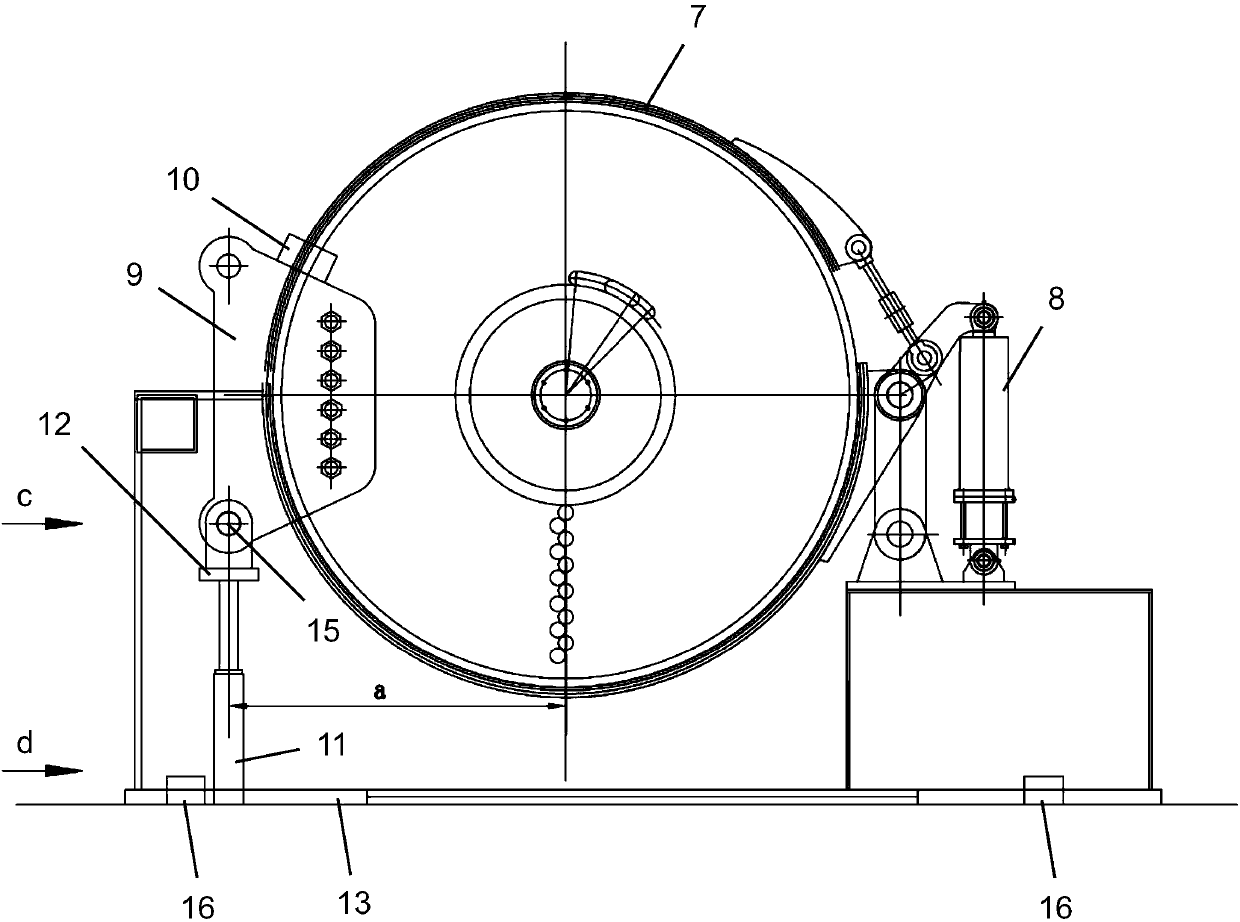

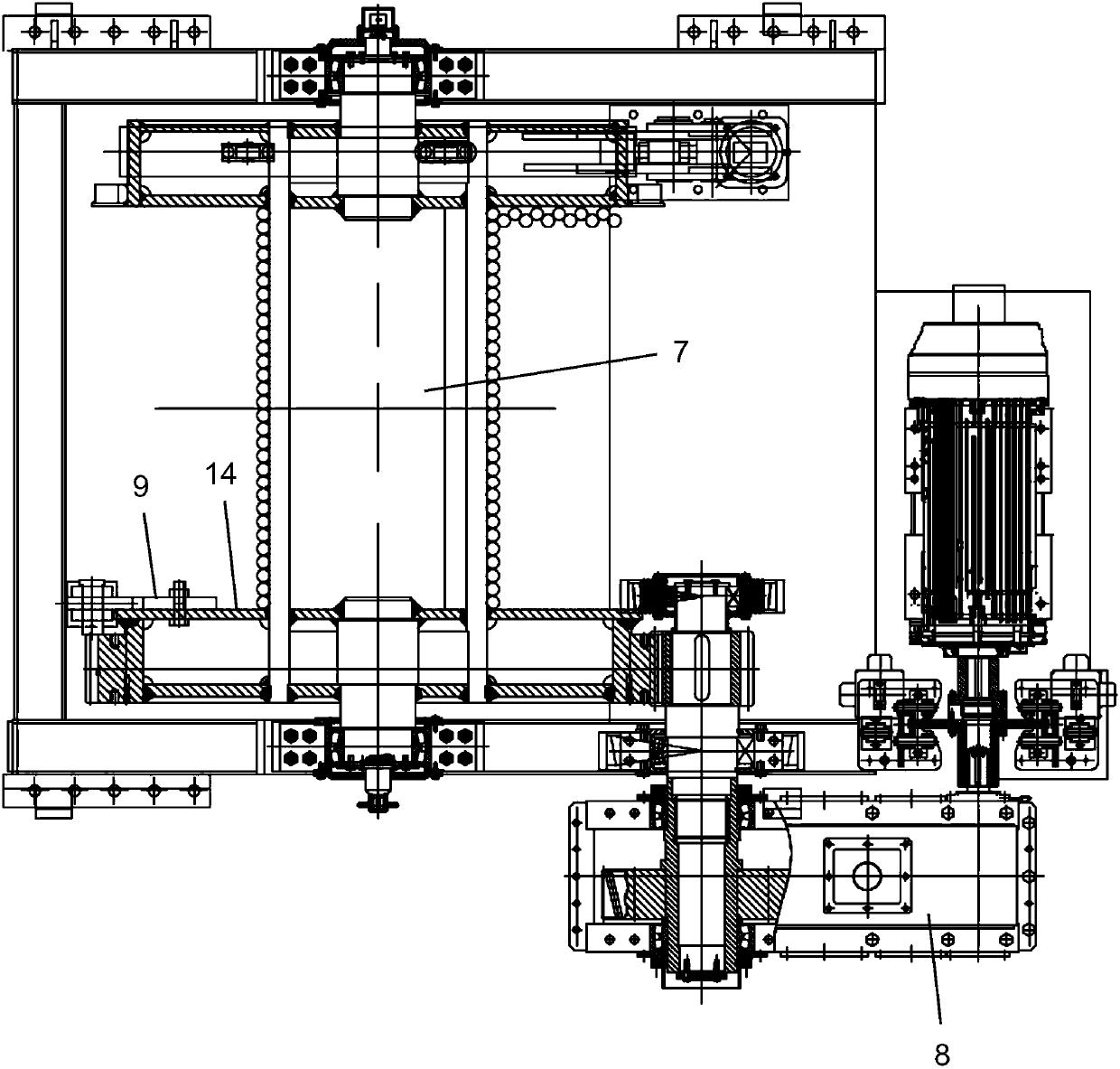

[0046] Please combine Figure 2 to Figure 5 As shown, a supporting load test device for a winch provided by the present invention includes a reel 7 and a band brake 8 for braking the reel 7, in addition, it also includes an extension plate 9 and a shear block 10 , a jacking hydraulic cylinder 11, a jacking winch 12 and a bottom plate 13 for carrying a fixed winch.

[0047] Preferably, the front side of the extension plate 9 is connected with the reel wall 14 of the reel 7, and the corner of the lower end of the extension plate 9 is connected with the upper end of the lifting winch 12 through a pin 15 to form a movable connection. The lower end of the lifting winch seat 12 is offset against the piston rod at the upper end of the jacking hydraulic cylinder 11 to receive the jacking force and transmit the jacking force to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com