Rapid detection device and method for horizontal winching machine

A technology of detection device and winch mill, which is applied in the direction of measuring device, machine/structural component testing, measuring fluid pressure, etc., can solve problems such as loud noise, unstable transmission, and demand, and achieve high safety factor and small test site , the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

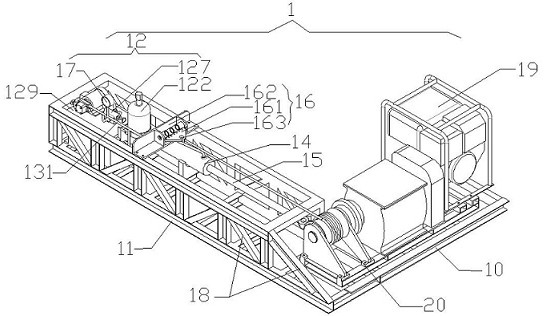

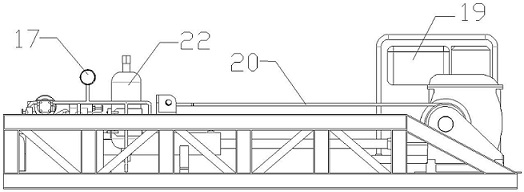

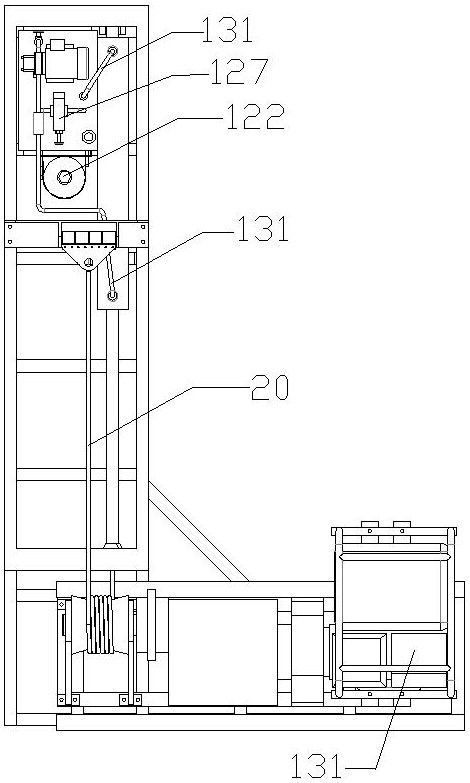

[0052] Such as Figure 1 to Figure 5As shown, a horizontal winch fast detection device 1 includes a first base 10 and a second base 11 fixed vertically to each other, the first base 10 is used to fix the winch 19 to be detected, and the first base 10 The two bases 11 are used to fix the hydraulic control device 12, the oil cylinder 14 and the oil rod 15; the oil rod 15 is located in the oil cylinder 14 and is movably connected with the oil cylinder 14; The base 11 is away from the end of the first base 10; the hydraulic control device 12 is connected to the oil cylinder 14 to control the movement of the oil rod 15, and the oil rod 15 moves along the axial direction of the oil cylinder 14; One end of the outer side of the oil rod 15 is used to connect with the head of the twisted rope 20 of the winch mill 19, and the tail of the twisted rope 20 of the winch mill 19 is fixed on the second base 11 through the tail rope automatic retracting device 16; The hydraulic control device...

Embodiment 2

[0058] Such as Figure 6 to Figure 9 shown, refer to Figure 6 , a method for quickly detecting a horizontal winch mill, comprising the steps of:

[0059] S1, fixing the winch mill to be detected on the first base;

[0060] S2. The winch mill quick detection device is fixed on the second base;

[0061] S3, fix the head and tail of the twisted rope of the winch mill;

[0062] S4, detecting the movement load of the winch;

[0063] S5, detecting the static load of the winch;

[0064] S6. Quick detection device for unloading winch mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com