Sludge circulating filtration integrated reactor and sewage treatment method

A sludge circulation and reactor technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of turbidity of factory water and low sludge concentration, and meet the guaranteed standards or reuse, high biomass, and strong resistance to changes in water quality and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

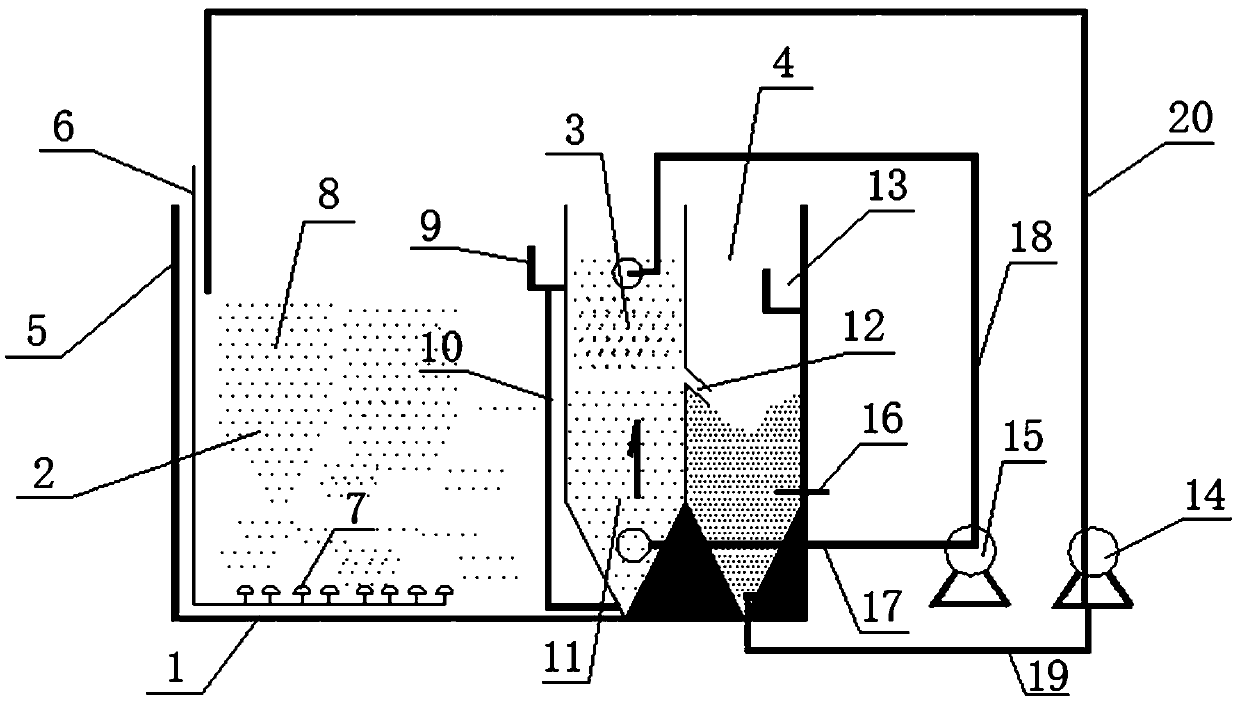

[0020] Specific implementation mode one: as image 3 As shown, this embodiment describes an integrated reactor for sludge circulation and filtration. The integrated reactor includes a box body 1, and aerobic activated sludge areas are arranged in the box body 1 from left to right. 2. Sludge circulation filter area 3 and water outlet area 4, the aerobic activated sludge area 2 contains activated sludge 8, and the left side of the aerobic activated sludge area 2 is provided with a water inlet pipe 5 and a blower air pipe 6 One end of the blower air pipe 6 communicates with the aeration head 7 arranged at the bottom of the aerobic activated sludge area 2, and one end of the water inlet pipe 5 communicates with the top of the aerobic activated sludge area 2, and the aerobic activated sludge The right side of area 2 is provided with a diversion pipe 10, the upper end of the diversion pipe 10 is provided with a sludge degassing weir 9, the lower end of the diversion pipe 10 communic...

specific Embodiment approach 2

[0021] Embodiment 2: The sludge circulation and filtration integrated reactor described in Embodiment 1, the tank 1 of the reactor is rectangular, square or cylindrical in shape.

specific Embodiment approach 3

[0022] Embodiment 3: The sludge circulation and filtration integrated reactor described in Embodiment 1 or 2, the tank 1 of the reactor is made of steel, glass fiber reinforced plastic, plexiglass or PP material.

[0023] Embodiment 4: In Embodiment 1, an integrated reactor for sludge circulation and filtration, the sludge circulation and filtration layer 11 is provided with a water distribution plate or a water distribution pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com