Novel gradient water permeable brick and manufacture method thereof

A technology of permeable bricks and gradients, applied in ceramic products, other household appliances, applications, etc., can solve problems such as blockage of permeable bricks and water loss, and achieve the effects of prolonging life, avoiding blockage, and solving road surface water and water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

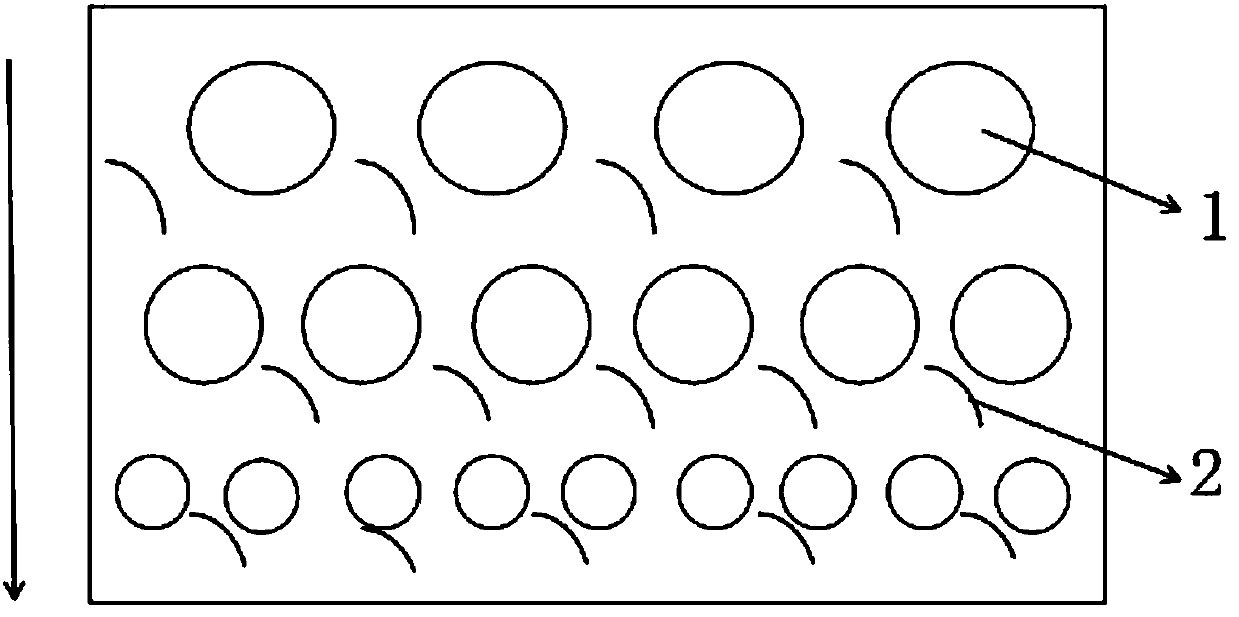

[0030] A new gradient permeable brick, by weight, the material ratio is as follows:

[0031] 0.1mm-0.2mm waste ceramics 60%, kaolin 30%, 2mm graphene oxide fibers 20%;

[0032] 0.5mm-2mm waste ceramics 60%, kaolin 30%, 2mm graphene oxide fibers 20%;

[0033] 2mm-10mm waste ceramics 60%, kaolin 30%, 2mm graphene oxide fiber 20%;

[0034] Put the mixture into a mold of 100mm×l00mm×40mm, compact and demould, put the green body into a tunnel furnace for firing, control the heating rate at 20°C / min, fire at a temperature of 180-220°C, and keep warm for 0.5h; Finished product A is made by spraying water after the tunnel furnace.

Embodiment 2

[0036] A new gradient permeable brick, by weight, the material ratio is as follows:

[0037] 0.1mm-0.2mm waste ceramics 70%, kaolin 20%, 2mm graphene oxide fibers 10%;

[0038] 0.5mm-2mm waste ceramics 70%, kaolin 20%, 2mm graphene oxide fiber 10%;

[0039] 2mm-10mm waste ceramics 70%, kaolin 20%, 2mm graphene oxide fiber 10%;

[0040] Put the mixture into a mold of 100mm×l00mm×40mm, compact and demould, put the green body into a tunnel furnace for firing, control the heating rate at 20°C / min, fire at a temperature of 180-220°C, and keep warm for 0.5h; Finished product B is made by spraying water after the tunnel furnace.

Embodiment 3

[0042] A new gradient permeable brick, by weight, the material ratio is as follows:

[0043] 0.1mm-0.2mm waste ceramics 80%, kaolin 10%, 2mm graphene oxide fiber 10%;

[0044] 0.5mm-2mm waste ceramics 80%, kaolin 10%, 2mm graphene oxide fibers 10%;

[0045] 2mm-10mm waste ceramics 80%, kaolin 10%, 2mm graphene oxide fiber 10%;

[0046] Put the mixture into a mold of 100mm×l00mm×40mm, compact and demould, put the green body into a tunnel furnace for firing, control the heating rate at 20°C / min, fire at a temperature of 180-220°C, and keep warm for 0.5h; The finished product C is made by spraying water after the tunnel furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com