Annular multi-tube pyrolysis oil sludge and waste tire waste plastic domestic garbage reaction device

A technology of domestic waste and reaction devices, which is applied in special forms of dry distillation, petroleum industry, indirect heating dry distillation, etc., and can solve problems such as increased floor space, long equipment, and inability to transport equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in conjunction with the following examples.

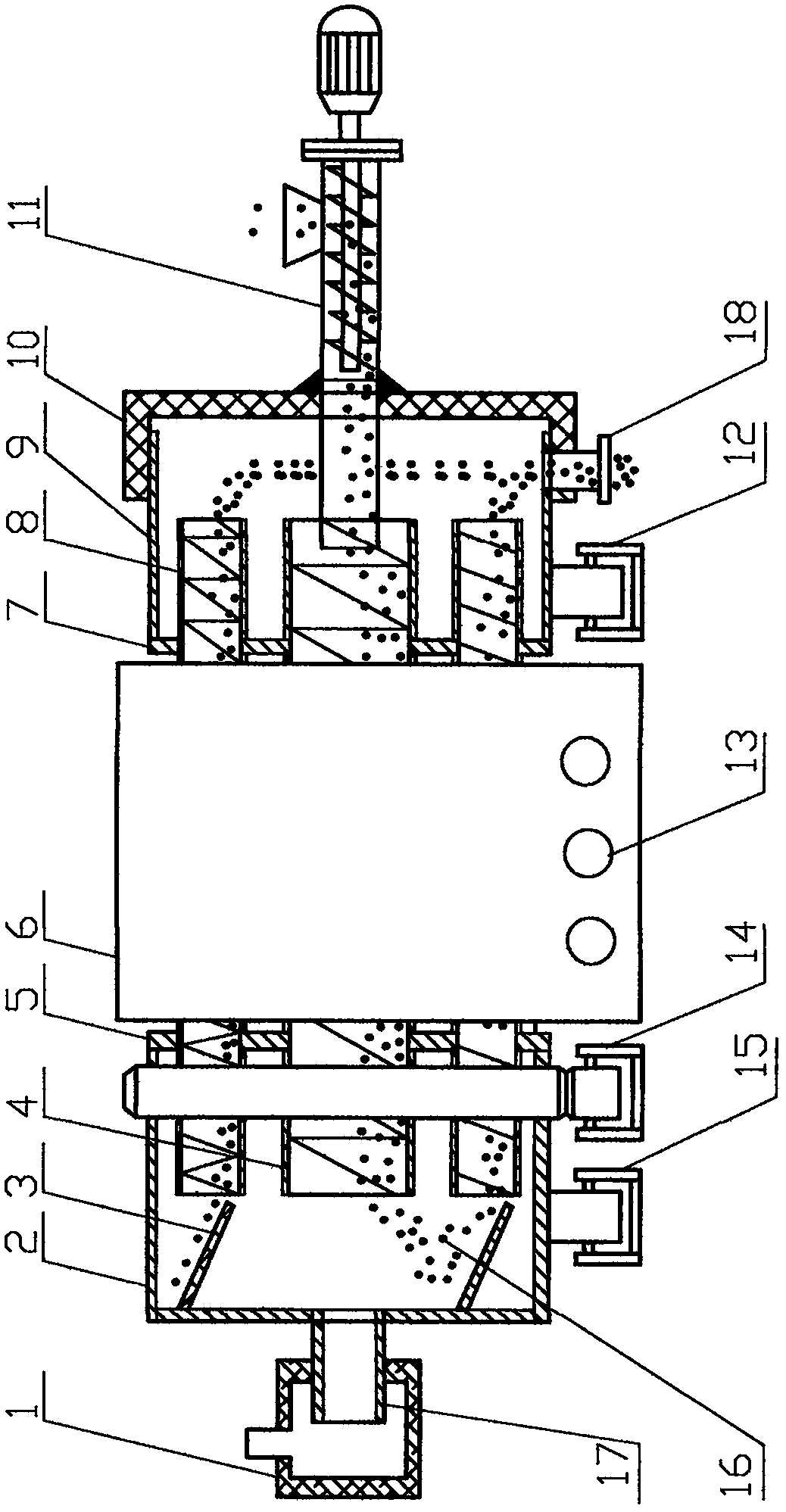

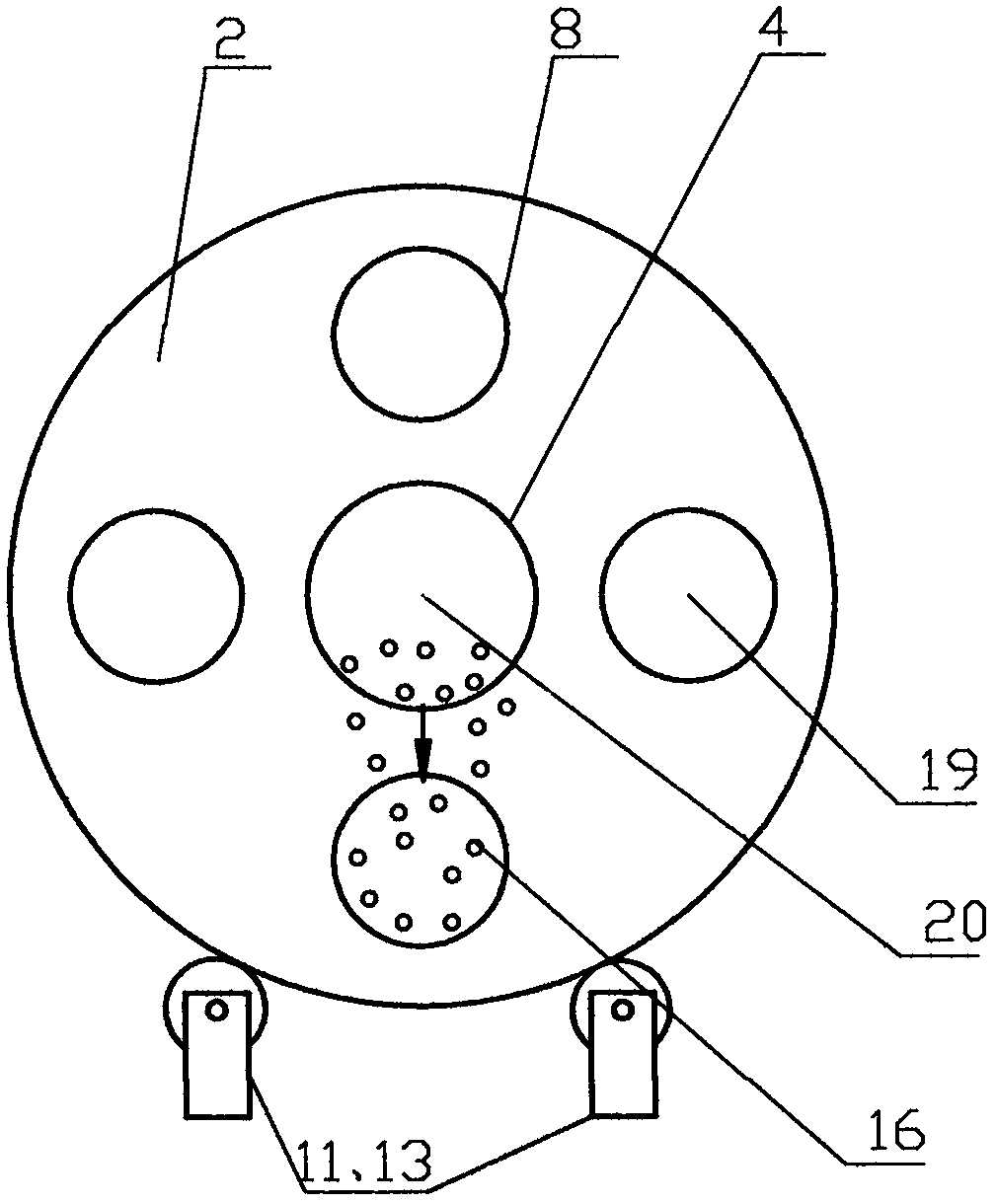

[0018] A kind of annular multi-pipe type pyrolysis oil sludge of this embodiment, waste tire waste plastic household garbage reaction device, the present invention is made up of left sealing sleeve (1), left chamber body (2), sliding material plate (3), center kettle ( 4), left fixed plate (5), heating furnace (6), right fixed plate (7), surrounding kettle (8), right cavity (9), right sealing sleeve (10), feeder (11) , the right supporting roller (12), the transmission wheel (14), and the left supporting roller (15) is formed, wherein in the peripheral circular hole (18) of the left fixed plate (5) and the right fixed plate (7), it is fixed with surrounding kettle ( 8), and in the central circular hole (19), a central kettle (4) is fixed; a left cavity (2), a right cavity (9) are respectively arranged on the outside of the surrounding kettle (8); in the left cavity ( 2) The outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com