Intelligent external inspection and maintenance vehicle for rail beam of suspension monorail transit

A monorail transportation, inspection and maintenance technology, applied in railway inspection vehicles, tracks, roads, etc., can solve problems such as poor sealing of track beam joints, manual maintenance of track beams, and cracks in track beams, and achieve the effect of improving maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and embodiments.

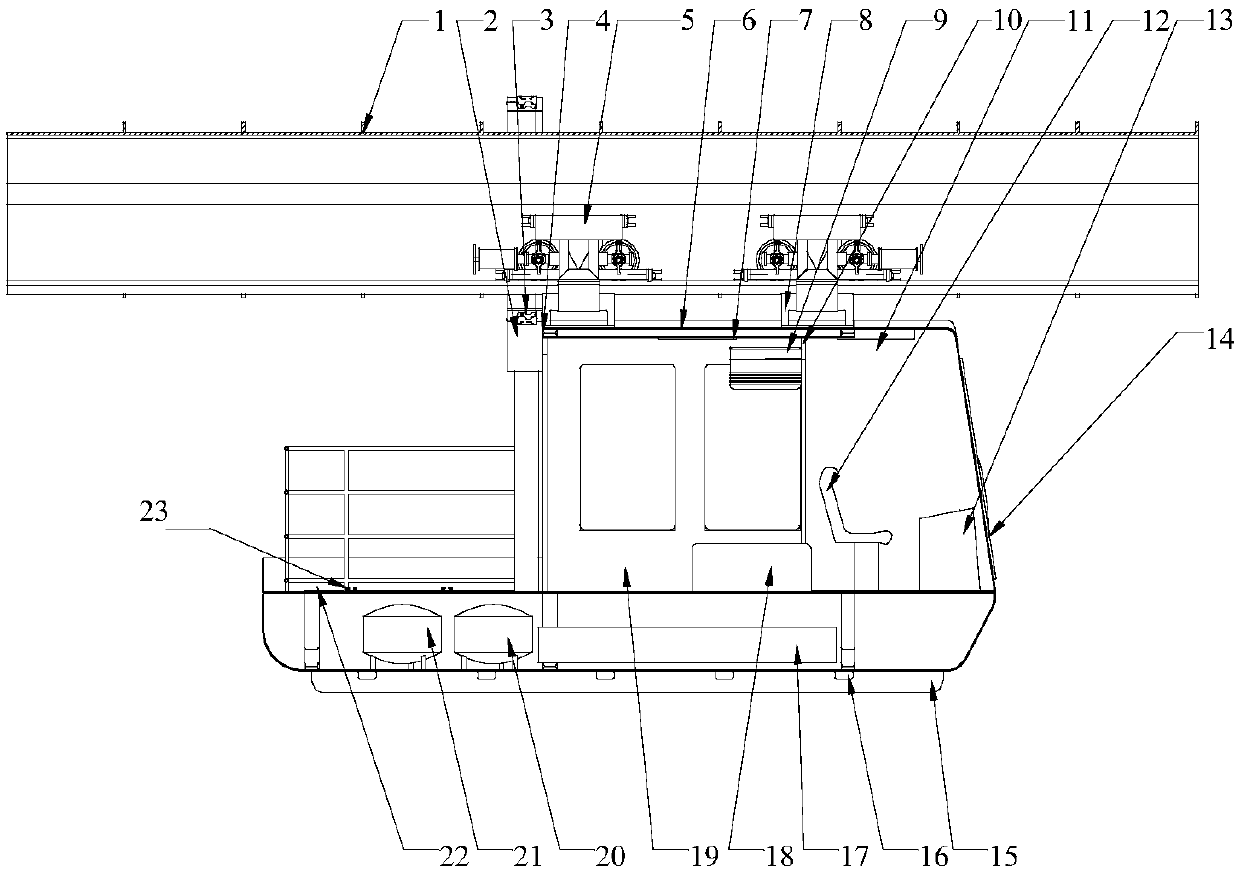

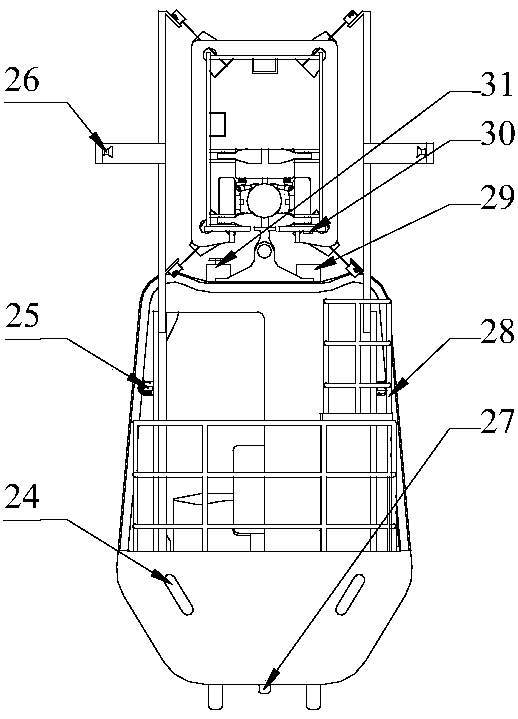

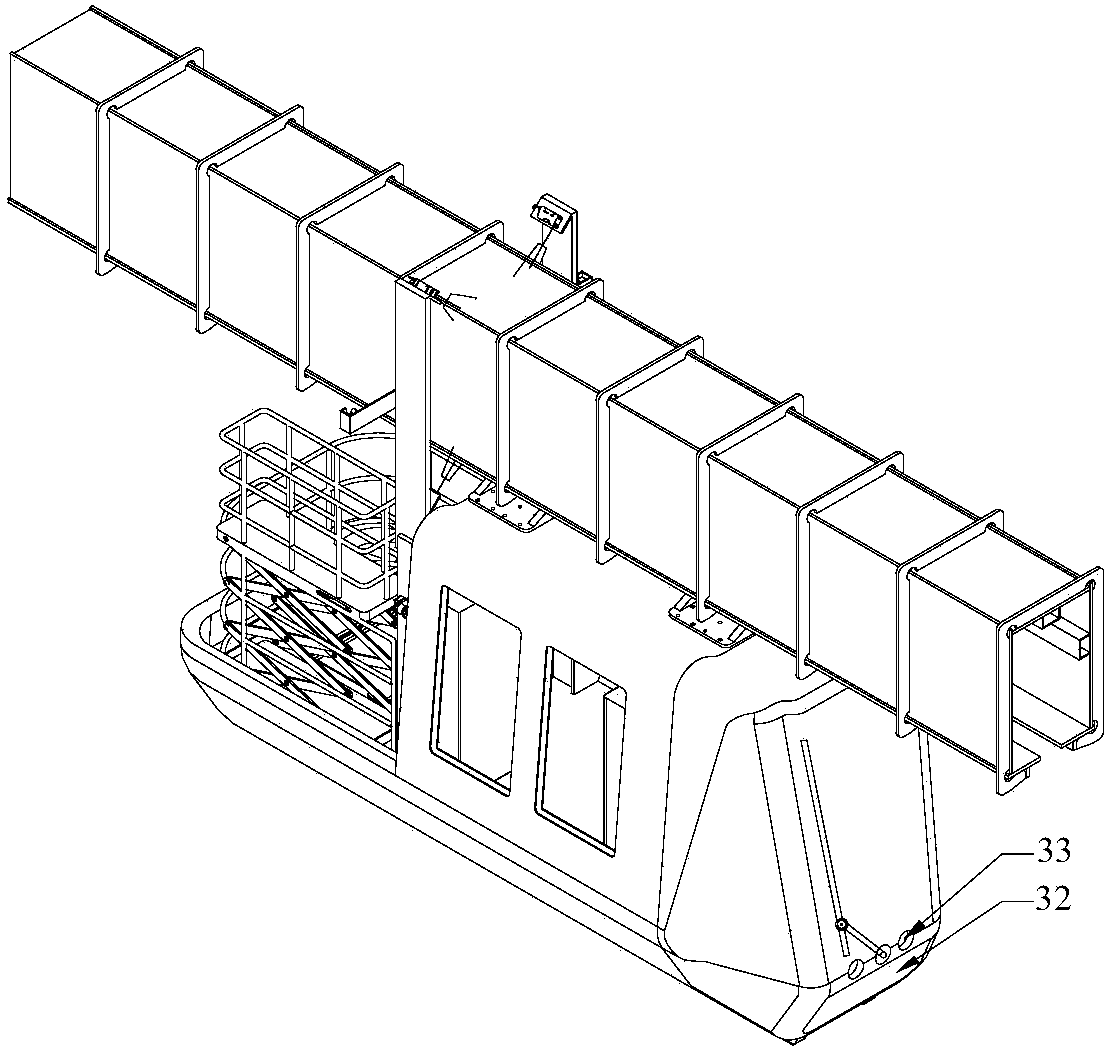

[0015] See Figure 1 to Figure 4 The external intelligent inspection and maintenance vehicle for suspended monorail transit track beams of the present invention includes an inspection vehicle frame 4, an inspection vehicle housing 6, a driving unit, a driving control unit, an intelligent detection unit and a safety protection unit.

[0016] The driving unit is mainly composed of a suspended bogie 5 and a power battery 17.

[0017] The driving control unit is mainly composed of a programmable logic controller (PLC) and an industrial computer.

[0018] The intelligent detection unit is mainly composed of a contour detector 3, a limit detection laser sensor 25, a rust detection camera 26, and a sensor lifting bracket 2.

[0019] The main functional unit of the contour detector 3 is a high-precision laser displacement sensor; the laser transmitter shoots the visible red laser to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com