Straw-steel fabricated wall connecting device and connecting joint manufacturing method

A connecting device and assembled technology, applied to walls, building components, buildings, etc., can solve problems such as difficult application, waste of resources, complicated splicing operations, etc., to improve wind and earthquake resistance, reduce construction waste, and simplify the connection process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

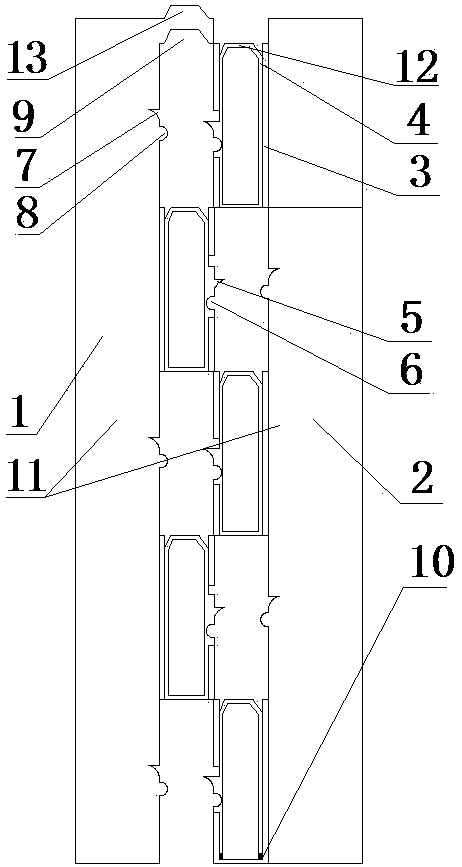

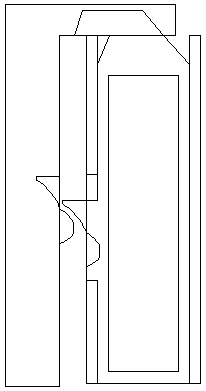

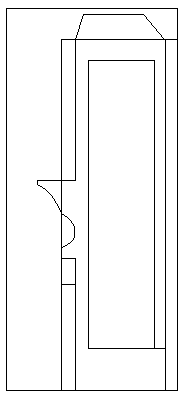

[0035] A straw-steel assembled wall connection device, which comprises: an assembled wall 11, the assembled wall is divided into a left wall 1 and a right wall 2, and the left wall Two sliding self-locking structures are welded, three sliding self-locking structures 3 are welded on the right side wall, the left side wall and the right side wall have a groove A7 and a protrusion A8 in the middle, The sliding self-locking structure has a slidable hollow metal 4 inside, the side of the slidable hollow metal has a slideway 5 and a groove B6, and the upper side of the slidable hollow metal has a protrusion B12.

Embodiment 2

[0037] According to the straw-steel fabricated wall connection device described in Embodiment 1, the upper end of the left wall has a trapezoidal groove 13 and a trapezoidal protrusion 9, and the slidable hollow metal upper end of the trapezoidal protrusion structure The dimensions are the same, and there is a spring device 10 at the lower part of the self-locking node at the bottom of the right wall.

Embodiment 3

[0039] According to the straw-steel fabricated wall connection device described in Example 1, the sliding self-locking structure can be an elastic self-locking structure, and the elastic self-locking structure has a slidable hollow metal inside, and the slidable Hollow metal bottom with compression spring. The bottom of the elastic self-locking structure has a trapezoidal groove, and the shape of the trapezoidal groove is the same as that of the slidable hollow metal trapezoidal protrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com