Connecting structure for SO2 flue gas pipelines and expansion joint

A connection structure, SO2 technology, applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, pipe components, etc., can solve the problems of flue gas leakage, pollute the environment, affect production, etc., and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific manufacturing process of the connection structure described in this application is as follows:

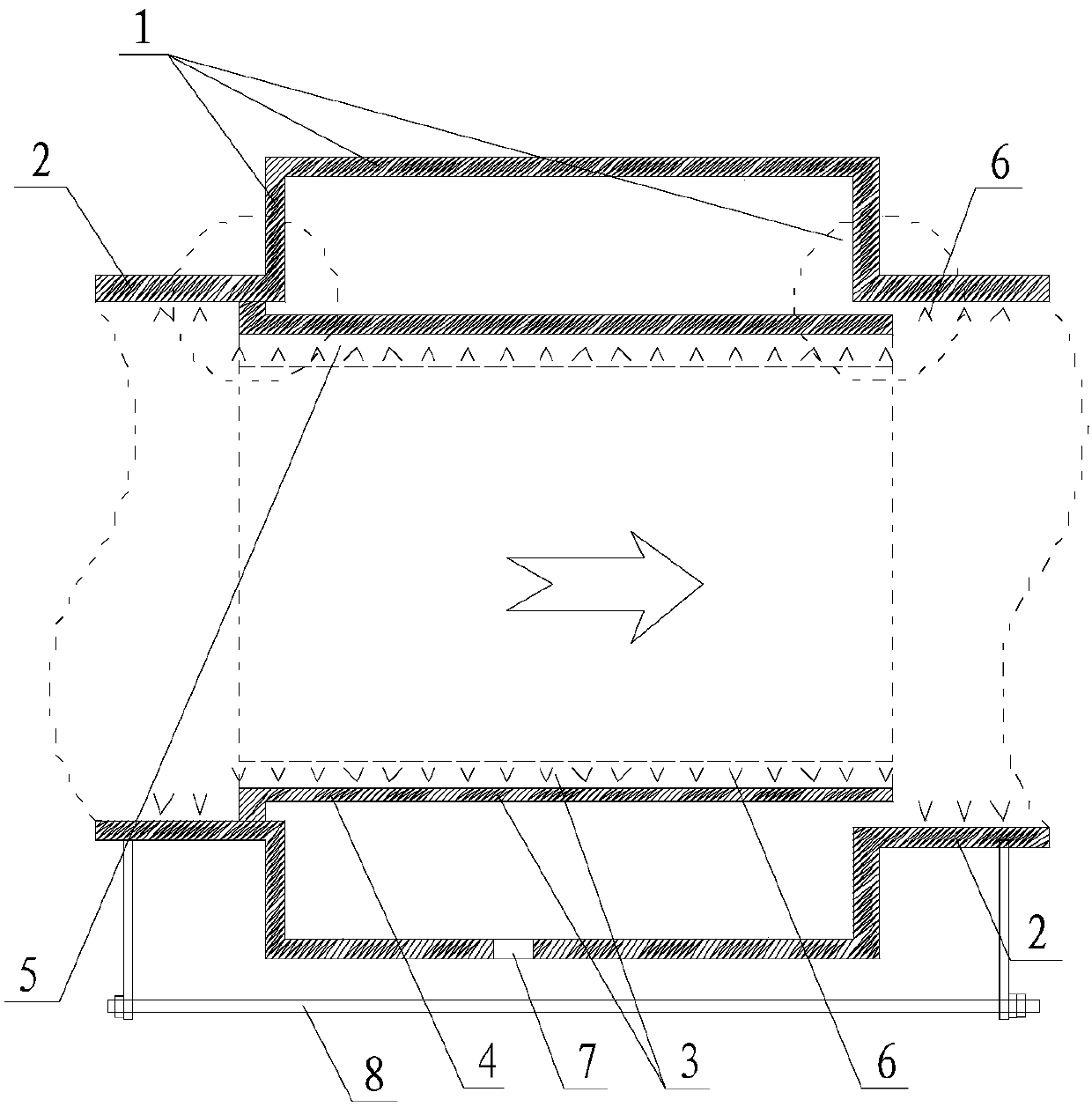

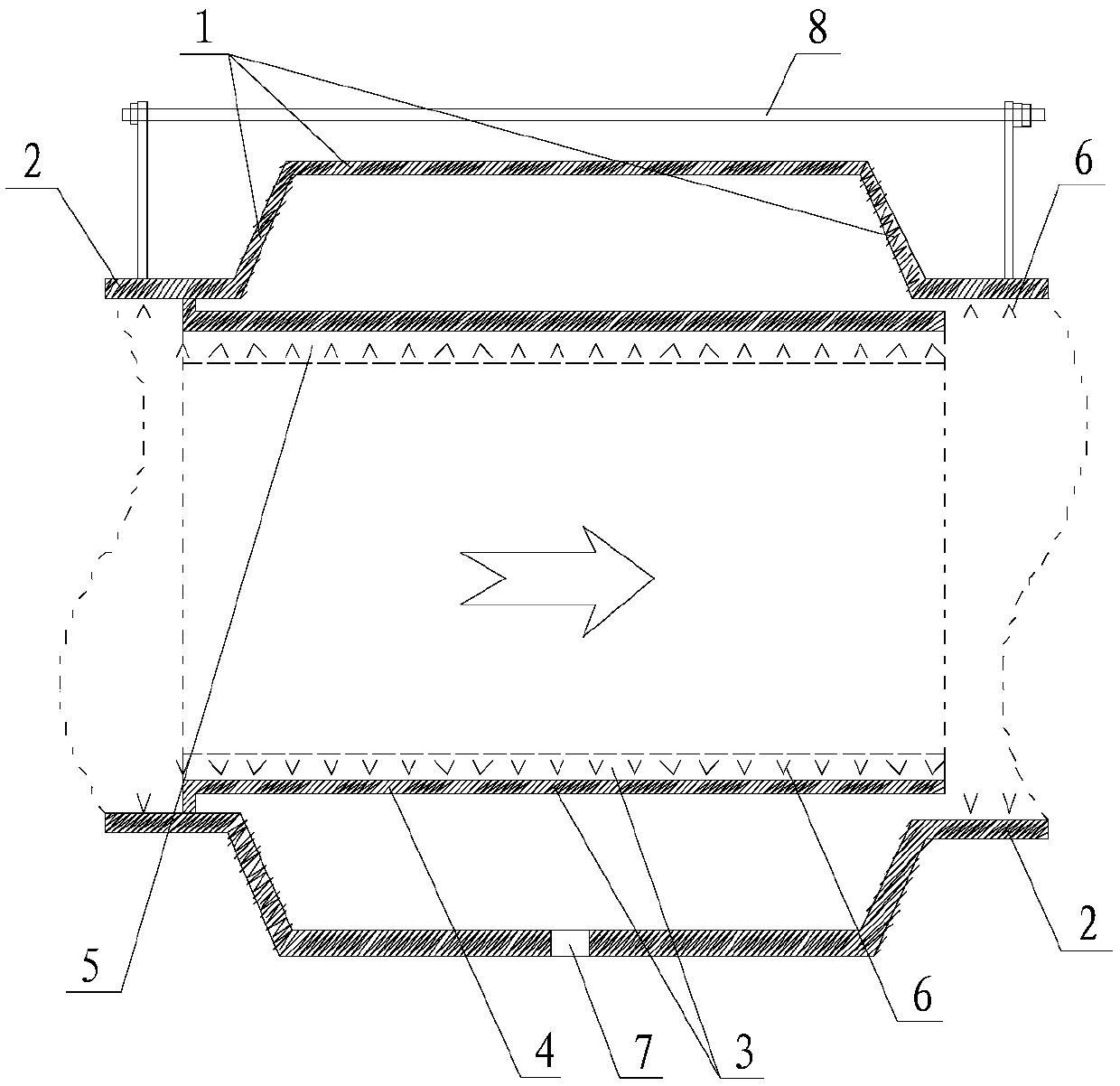

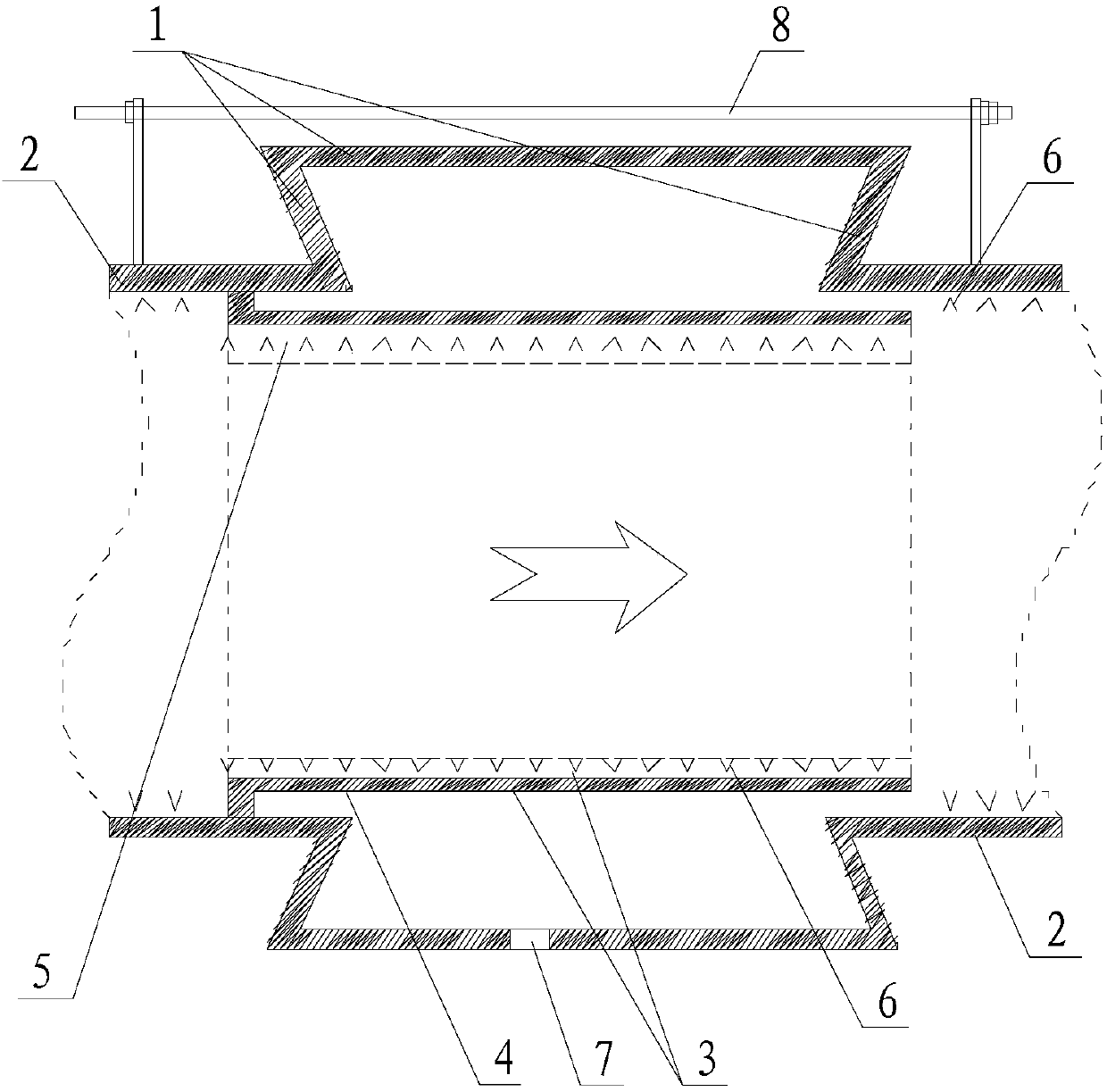

[0026] One, the composition of the connection structure described in this application

[0027] 1. Fabrication of the expansion joint body 1: the expansion body 1 includes "annular ribs", "telescopic corrugations" and "connectors" which are SO 2 A part of the flue gas pipeline 2 is isolated in this application to facilitate replacement. The "ring rib" can be made of 3mm thick 304 stainless steel, the inner diameter of the ring is the outer diameter of the pipe, and the height of the rib should be between 250mm and 300mm. The "stretch corrugation" can be made of 5mm thick 304 stainless steel coil, and the corrugation width should be between 1000mm and 1200mm. The "connecting pipe" is made of 304 stainless steel coiled plate, the length should be between 300mm and 400mm, and the wall thickness of the coiled plate should be equal to the wall thickness of the flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com