Pipeline system with data acquisition function

A data acquisition and assembly line technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high degree of automation and low efficiency of assembly line data collection, and achieve the effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

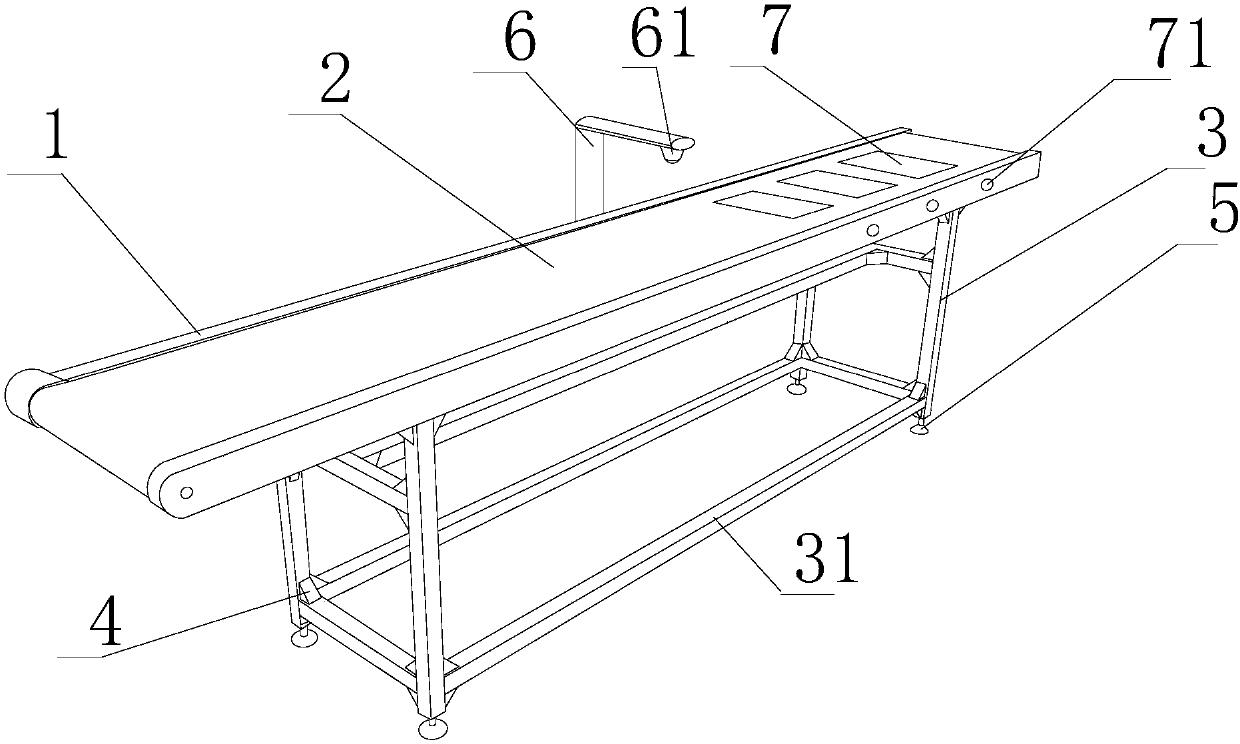

[0022] Such as figure 1 As shown, the assembly line system with data acquisition function includes an assembly line workbench 1, a CCD sensor 61, a sensor bracket 6, and at least three weight detectors 7. The assembly line workbench 1 is provided with a work area 2 and at least three indicator lights 71, a conveyor belt is laid on the working area 2, and all the indicator lights 71 are arranged on the side of the assembly line workbench 1; the CCD sensor 61 includes a detection unit and a display unit, and the detection unit is located in the working area 2 Directly above, the detection unit is used to detect the color and shape information of the product conveyed by the conveyor belt, the display unit is electrically connected to the detection unit, and the display unit is used for the user to watch and check; the CCD sensor 61 is arranged on One end of the sensor bracket 6, the other end of the sensor bracket 6 is connected with the assembly line workbench 1; all the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com