Object volume measuring system and method

A volume measurement and object technology, applied in the field of measurement, can solve problems such as inaccurate height measurement, object billing, impact on transportation and storage, and impact on user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

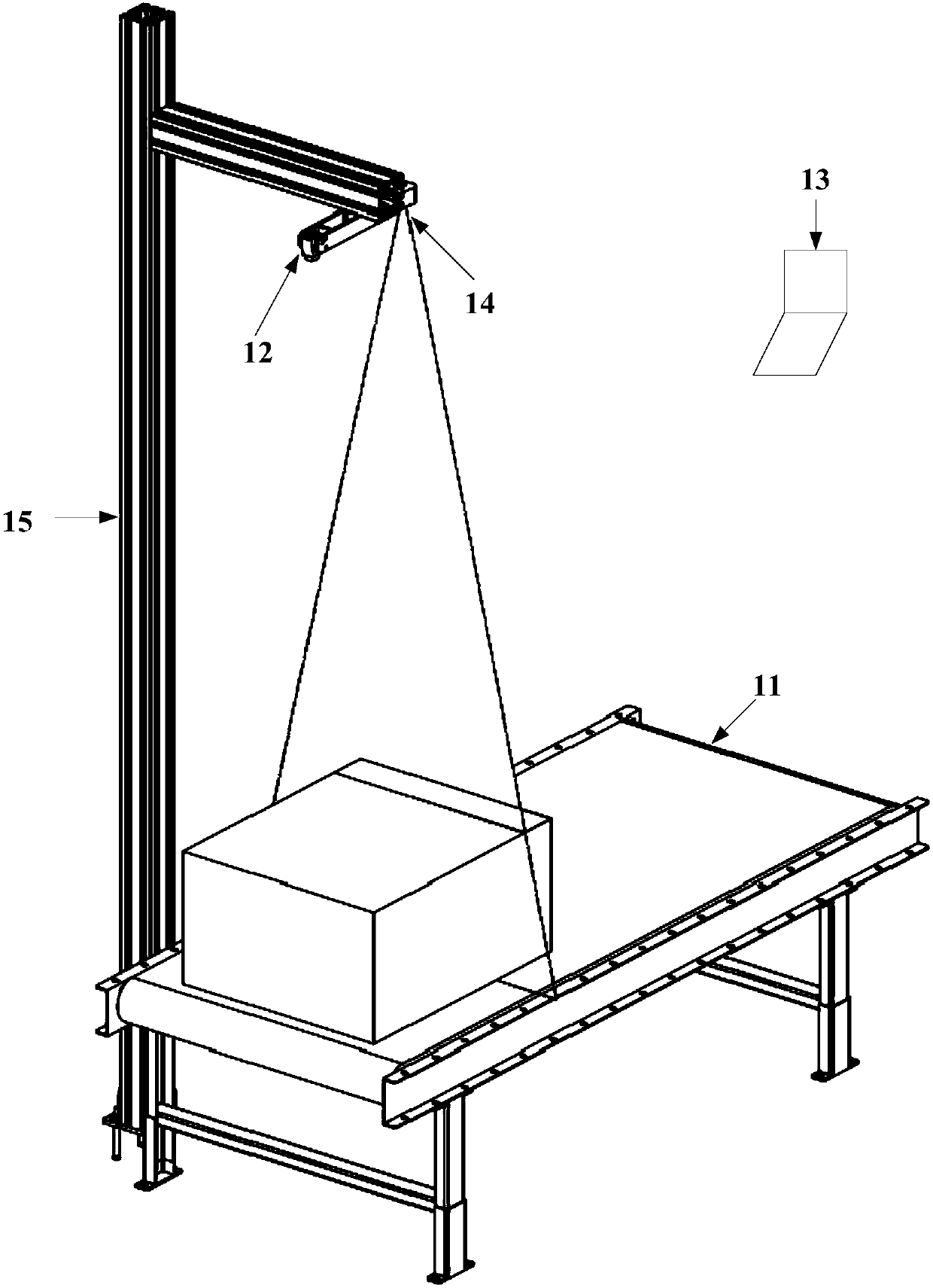

[0032] Figures 1A-1B An installation diagram of an object volume measurement system provided by an embodiment of the present invention, the system includes a conveyor belt 11, an image acquisition device 12 and an image processing device 13, and the system also includes: a line laser 14; wherein, the image acquisition device 12 and The line laser 14 is arranged above the conveyor belt 11; the system also includes an L-shaped bracket 15 for fixing the image acquisition device 12 and the line laser 14;

[0033] a line laser 14 for emitting a laser line onto the conveyor belt 11;

[0034] The image acquisition device 12 is used to collect the first picture containing the laser line on the conveyor belt 11 according to the set time interval, and send each first picture collected to the image processing device 13;

[0035] The image processing device 13 is configured to receive each first picture sent by the image acquisition device 12, and determine each first picture by using the ...

Embodiment 2

[0043] In order to improve the accuracy of measuring the height of the object, on the basis of the above-mentioned embodiments, in the embodiment of the present invention, the image processing device 13 is specifically configured to perform point-to-point calculation of the first height of the object in each first picture. Cloud denoising, according to each first height of the object after point cloud denoising, determine the target height of the object.

[0044] Specifically, for the first height of the object in each first picture, a preset point cloud denoising algorithm, such as: K-nearest neighbor algorithm, is used to remove the noise points in the first height of the object, and according to the point cloud after denoising For each first height of the object, determine the target height of the object, for example: determine the target height of the object according to the average value of each first height of the denoised object; or determine the target height of the obj...

Embodiment 3

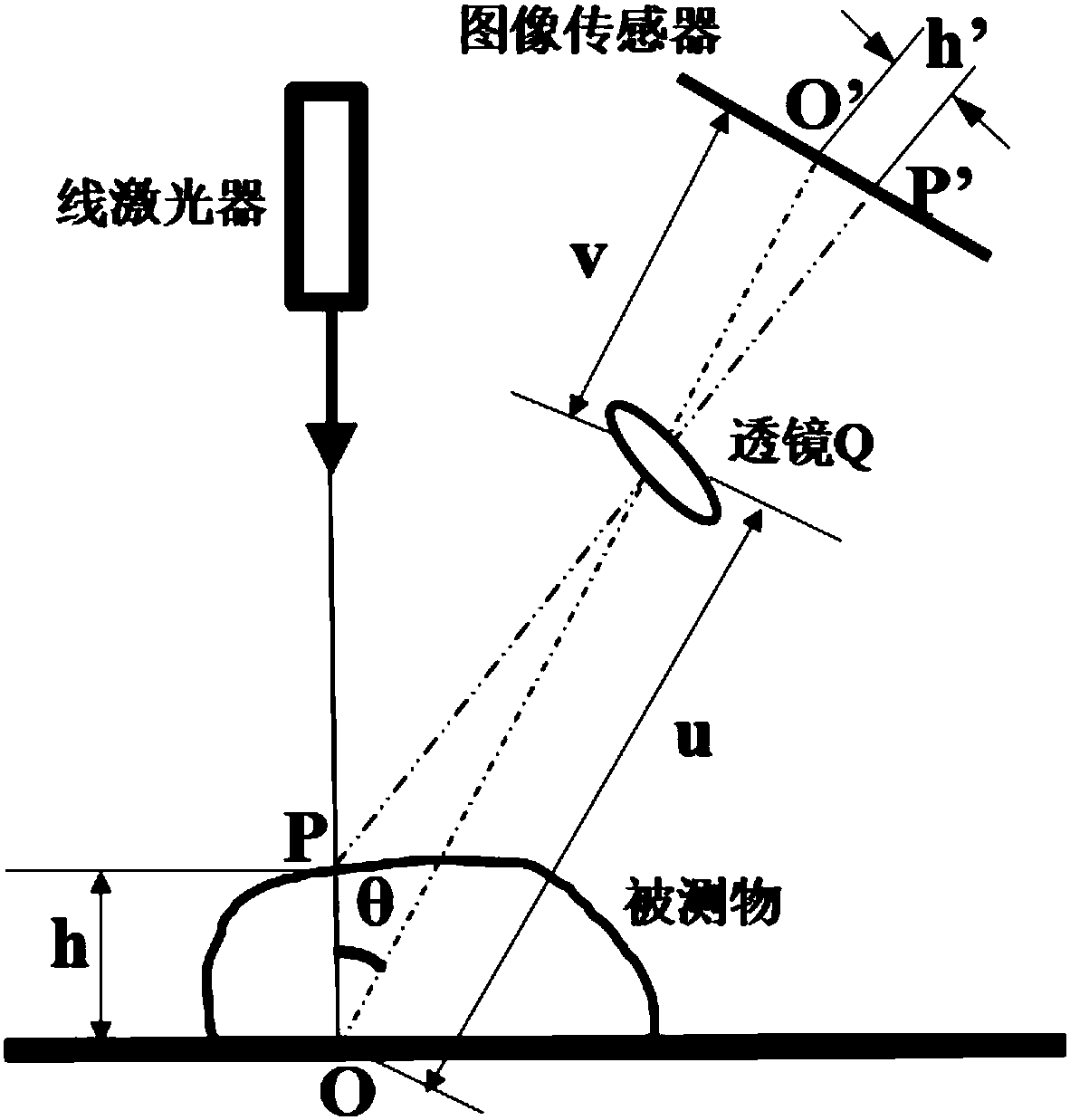

[0046] In order to accurately obtain the height of the object, on the basis of the above embodiments, in the embodiment of the present invention, the image processing device 13 is specifically used to Determine the first height of the object, where h is the first height of the object, u is the distance between the center point of the laser line emitted onto the conveyor belt and the center point of the lens of the image acquisition device, and v is the center point of the lens of the image acquisition device , the distance from the center point of the laser line emitted to the conveyor belt projected onto the image sensor of the image acquisition device, θ is the connecting line between the center point of the laser line emitted on the conveyor belt and the center point of the lens of the image acquisition device , and the angle between the center point of the laser line emitted onto the conveyor belt and the center point of the lens of the image acquisition device, h' is to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com