Collection method for fault analysis data of harbor machine

A technology of fault analysis and acquisition method, applied in the fault analysis of port machinery and the field of port machinery, it can solve problems such as lack of calculation and theoretical basis, omission, etc., to improve stability, avoid misjudgment, and reduce the need for storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

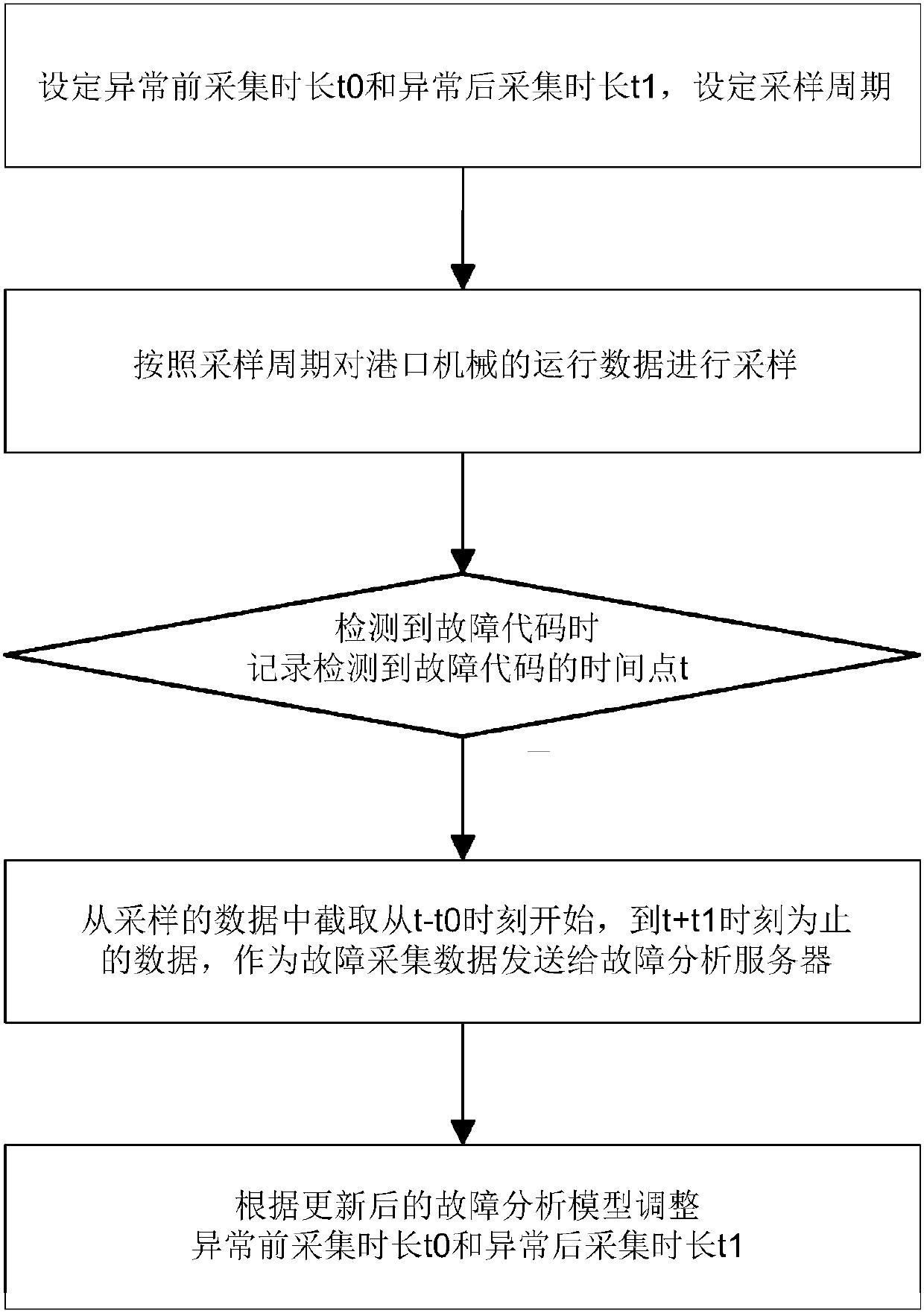

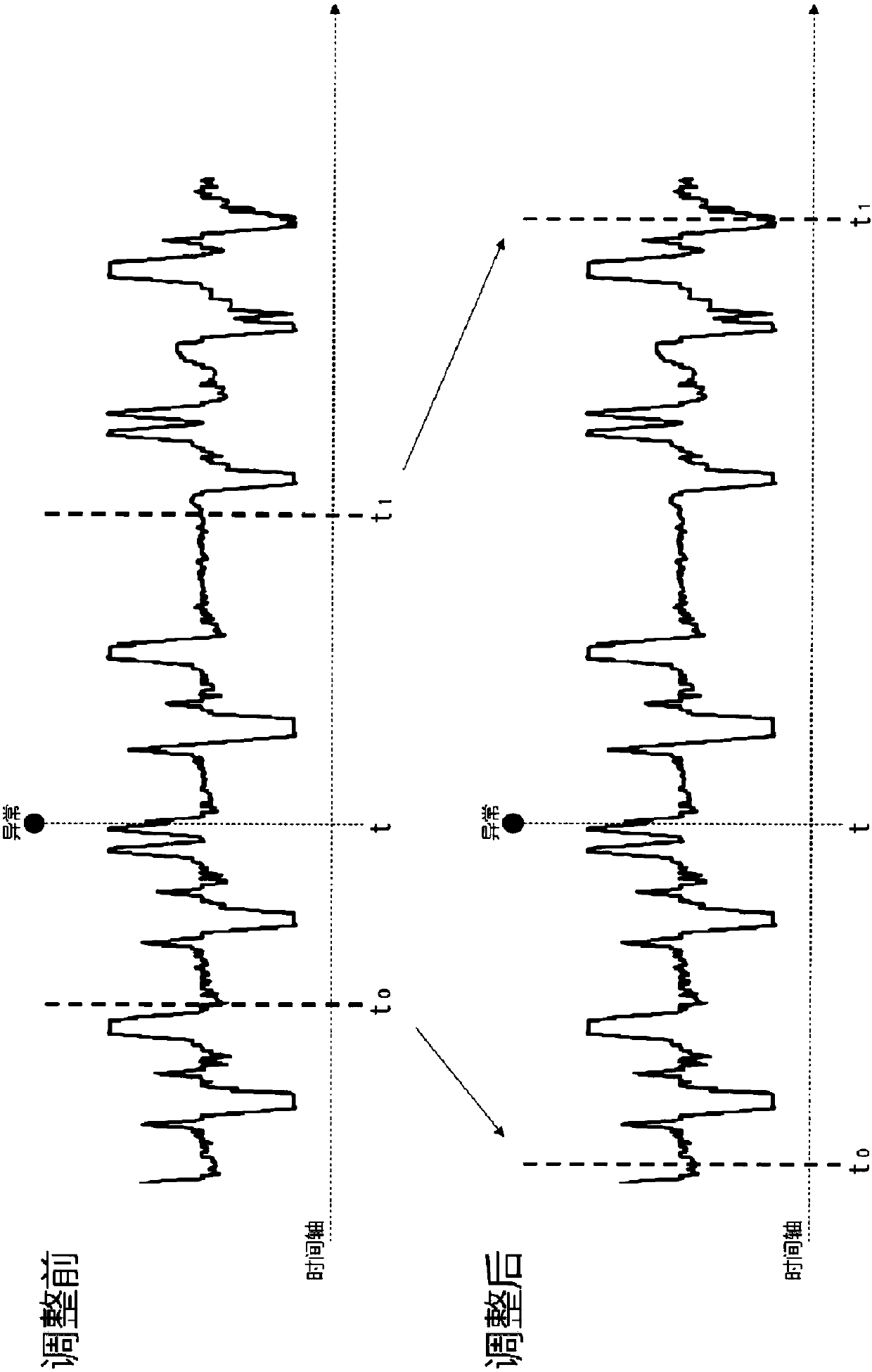

[0027] A large amount of data proves that the data related to the fault appears before and after the fault occurs. During a period of time before the failure, there will be some abnormal data with warning signs, and after the failure, abnormal data due to the failure will also be generated. In the rest of the time period, it is normal operation data, or in other time periods, even if there is abnormal data, it is usually noise data caused by interference or wrong collection. Therefore, if the collection of fault data is set before and after the occurrence of the fault, the accuracy of the collected data is high, and there is basically no need for identification and processing, and it can be used directly. Since the collection time period is only before and after the fault occurs, compared with the existing long-term collection, the collection time is greatly reduced, which can greatly reduce the amount of data and save storage space. Of course, the specific time period for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com