High-rotating-speed DC brushless motor control system and control method thereof

A brushless DC motor and control system technology, used in electrical components, electronic commutators, emergency protection circuit devices, etc., can solve problems such as hidden dangers of stable motor operation and inability to accurately control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

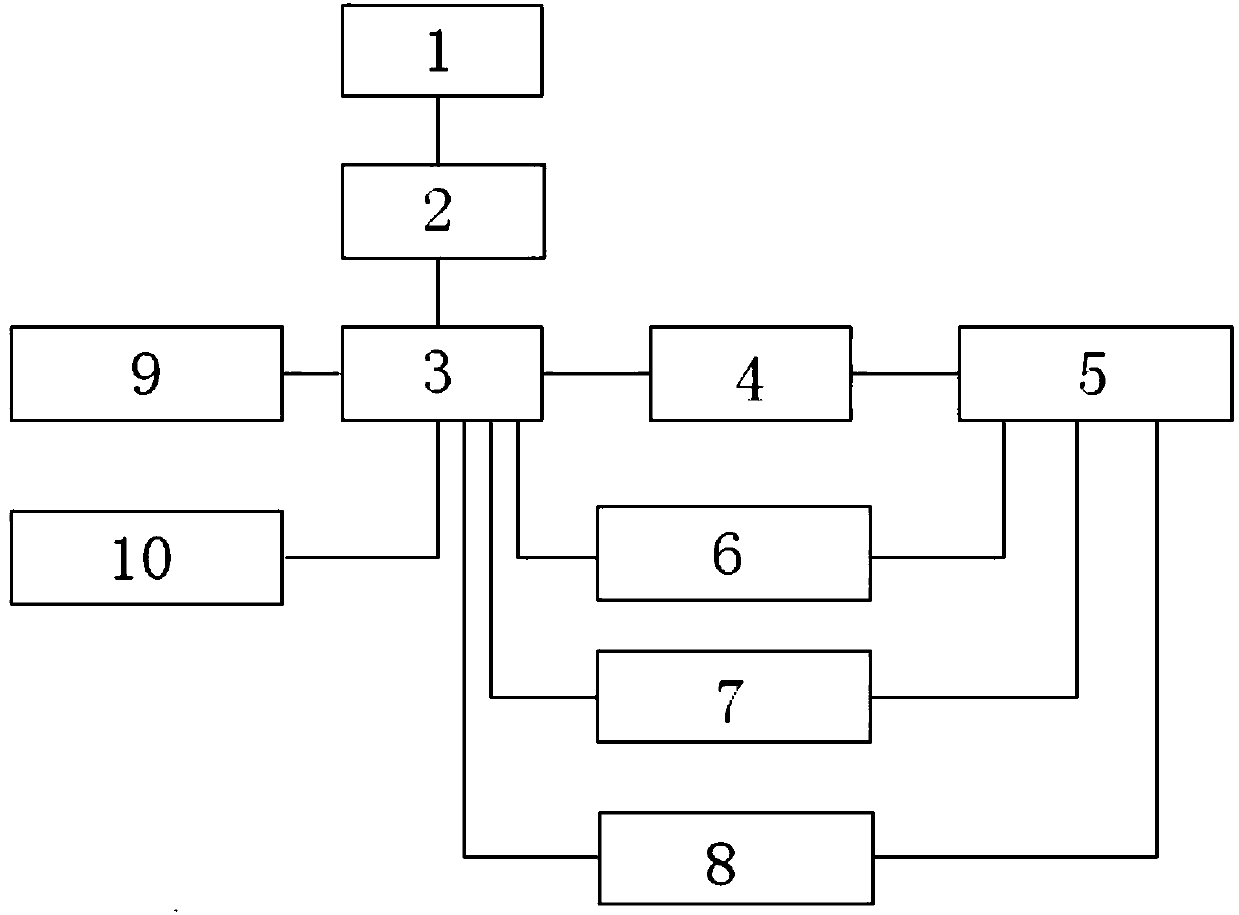

[0027] The high-speed brushless DC motor control system of the present invention includes a circular circuit board, a rectifier module 2, a controller 3 and an inverter module 4 arranged on the circuit board, and three Hall sensors 6, 7, 8, the circuit board is fixedly connected to the stator of the brushless DC motor 5 and the central perforation matches the rotor of the brushless DC motor, the stator, the rotor and the circuit board coaxial setting, the Hall sensor is connected with the controller in communication. The speed of the high-speed brushless DC motor is above 8000 rpm, and even the ultra-high-speed brushless DC motor is above 10000 rpm.

[0028] In the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com