Ultrafine pulverizing machine for fodder processing

An ultra-fine pulverizer and feed processing technology, which is applied in feed, application, grain processing, etc., can solve the problems of equipment energy consumption and noise, inconvenient processing, and easy heating of equipment, so as to prevent dust from entering the bearing and extend the service life The effect of life and improvement of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

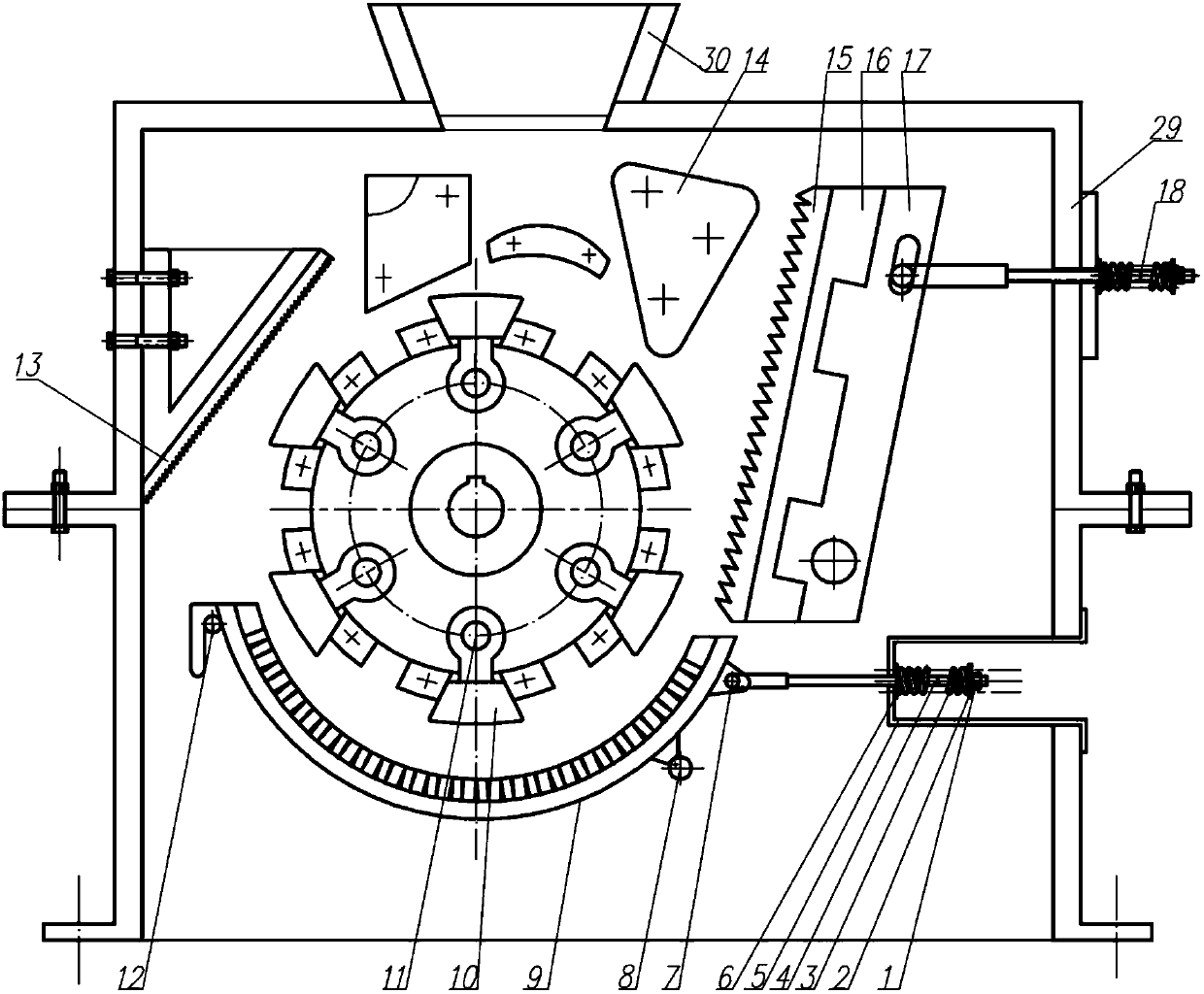

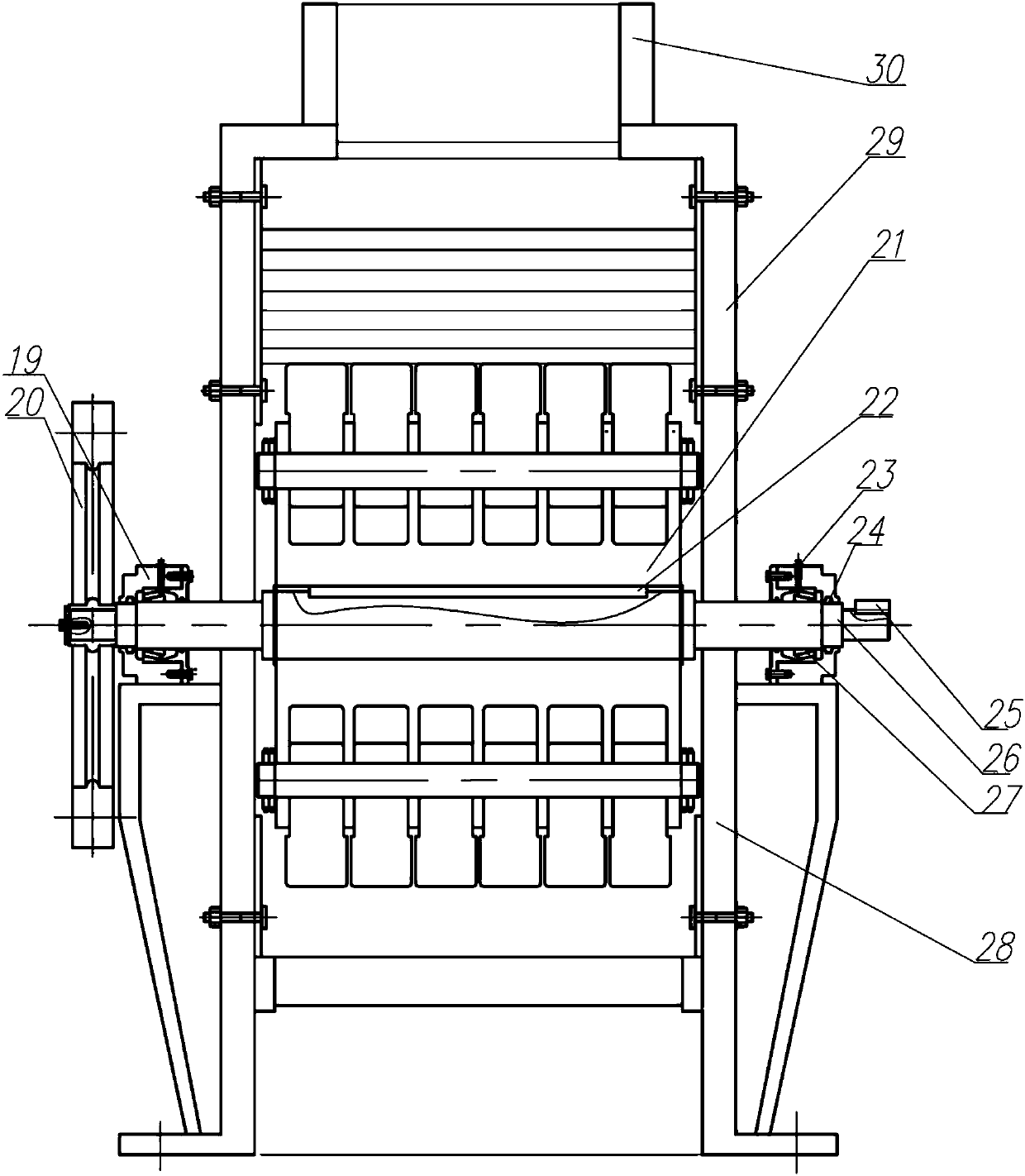

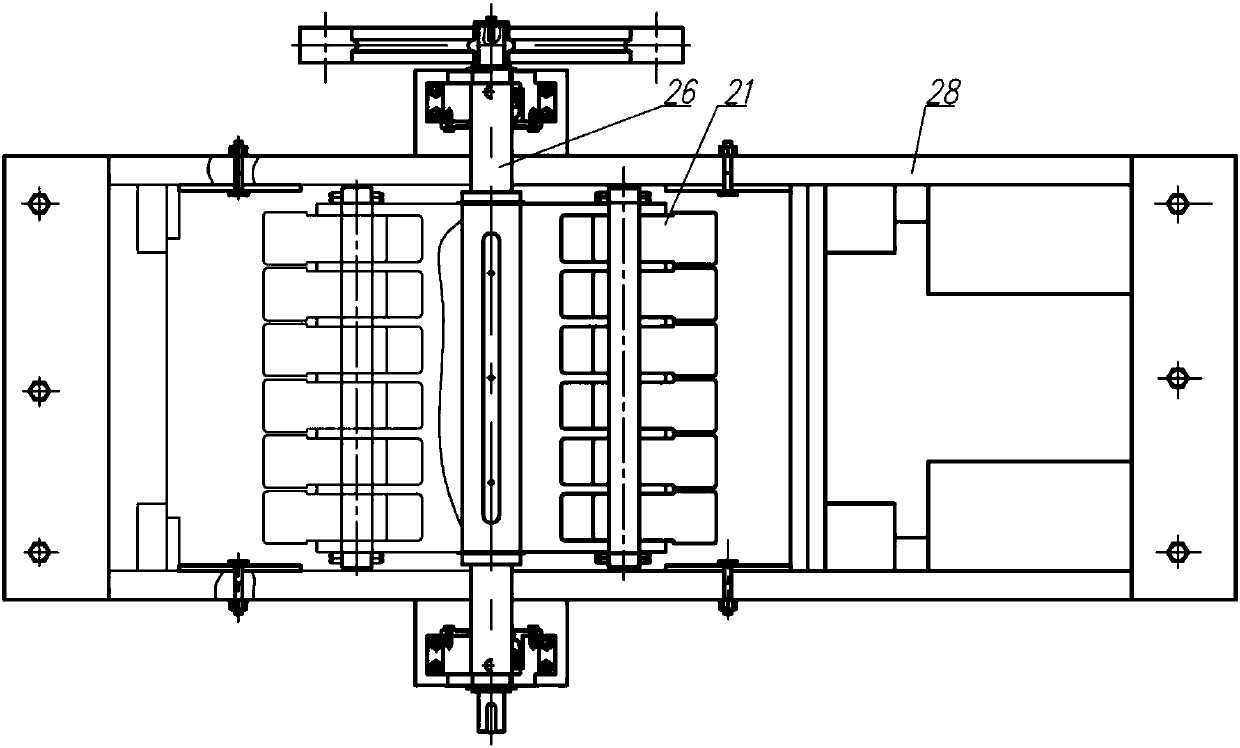

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] see Figure 1-3 , a kind of ultra-fine pulverizer for feed processing, it comprises base 28, and main shaft 26 is supported on the base 28, and the two ends of main shaft 26 are supported and installed on the base 28 by the bearing seat 19, and upper base 28 is fixedly installed Box 29, hammer frame 21 is installed on the main shaft 26, on the hammer frame 21 is hinged with hammerhead 10 through hammerhead pin shaft 11, the inside of box body of base 28 is equipped with grate bar 9, and the left end of grate bar 9 is hung by grate bar The pin 12 is hinged inside the base 28, the right end of the grating bar 9 is supported by the adjusting pin 8, and the right end of the grating bar 9 is equipped with a grating bar adjusting mechanism; An adjustable counterattack board 15 is connected with the counterattack board adjustment mechanism. The rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com