Plasma polishing device

A polishing device and plasma technology, applied in the field of metal surface treatment devices, can solve the problems of weak conductivity, failure to achieve automatic control, easy corrosion of the inner wall of the reaction tank, etc., achieving the effect of low cost and ensuring conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

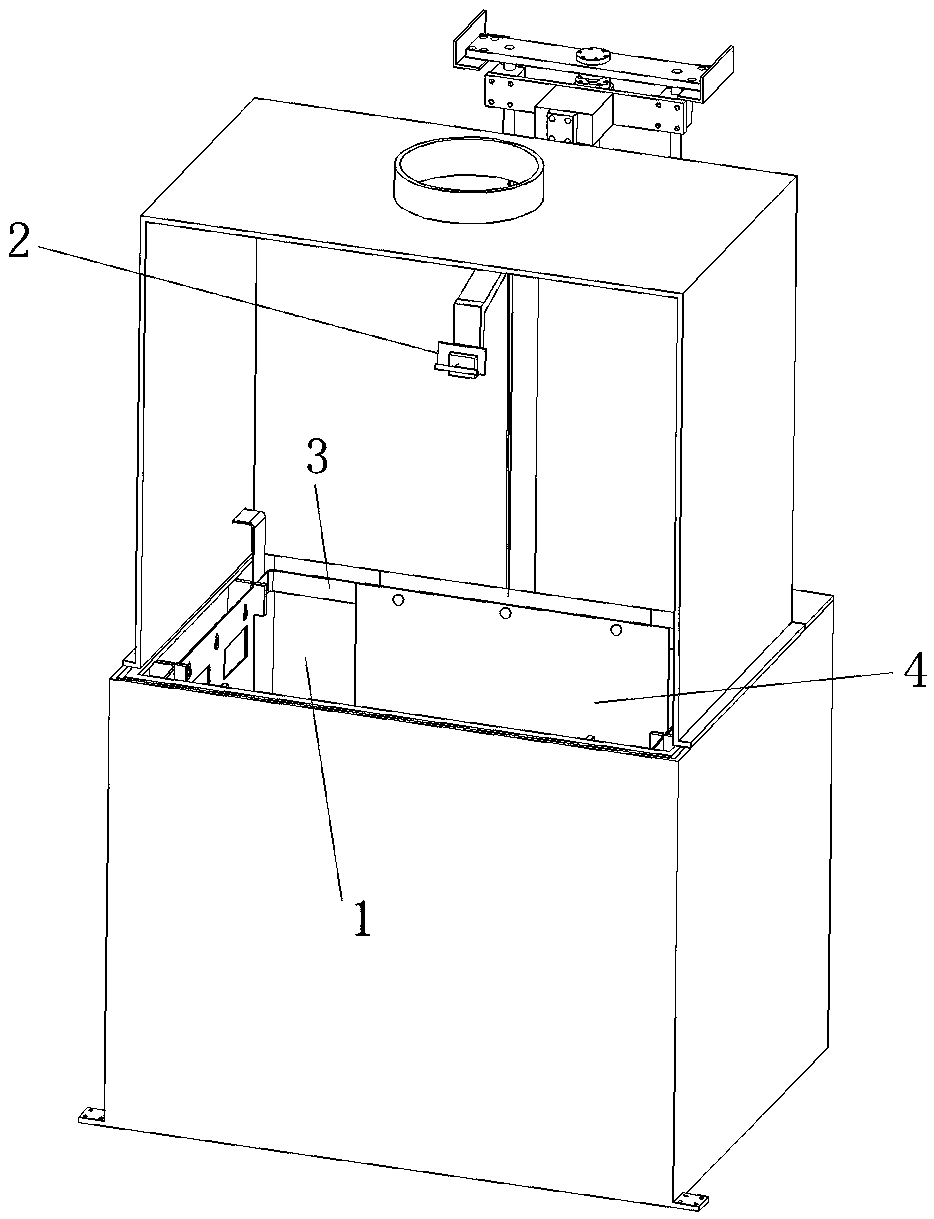

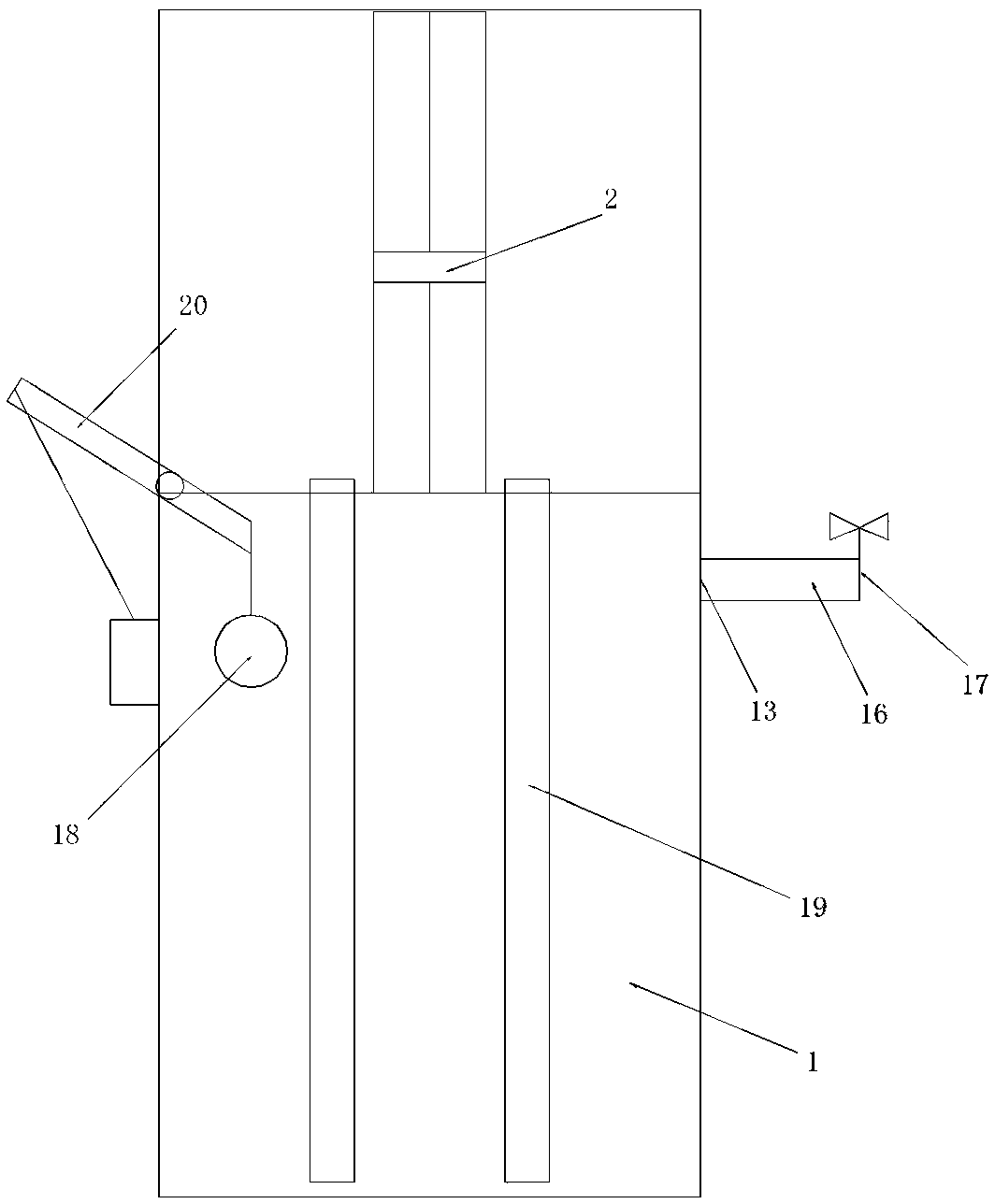

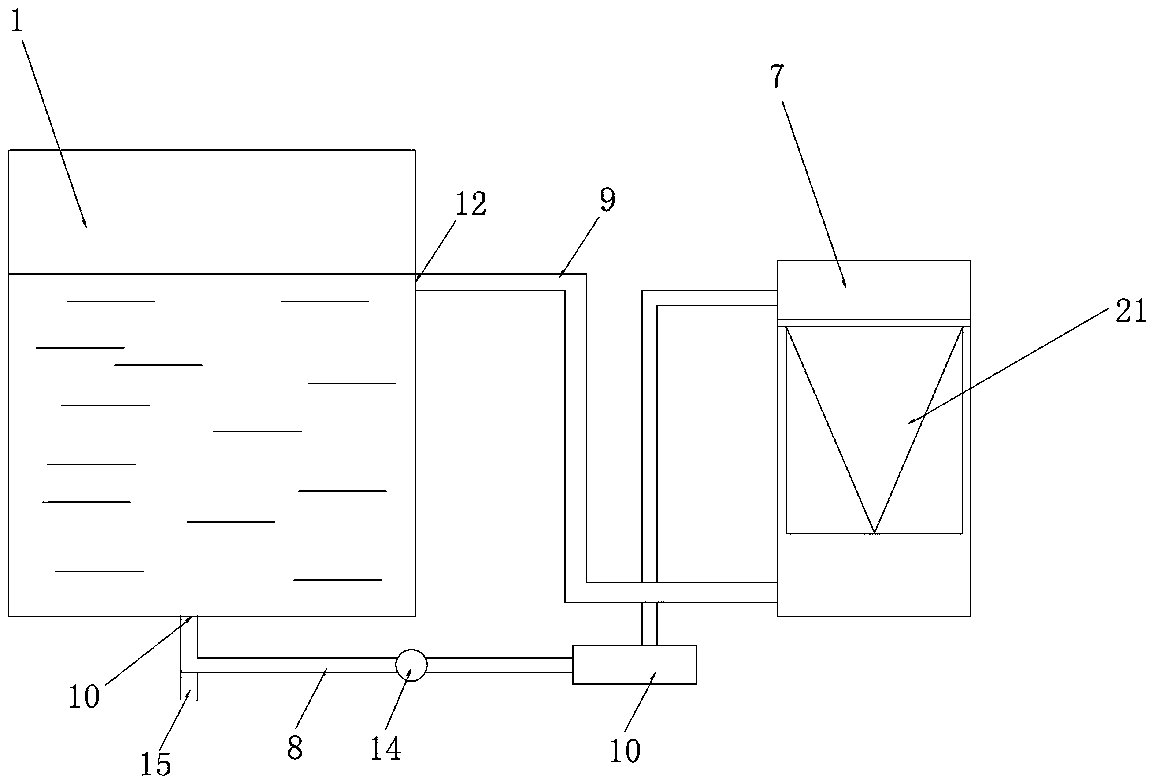

[0013] like figure 1 and Figure 4 As shown, a plasma polishing device includes a reaction tank 1, a DC stabilized power supply and a liquid circulation mechanism. The DC stabilized power supply is a high-frequency power supply, which can increase the conversion rate of electric energy. The top of the reaction tank 1 is provided with a material rack 2 that automatically goes up and down, and the material rack 2 is connected to the positive pole of the power supply. The reaction tank 1 is made of an iron plate 5 and two PPR plates 6. Between the two PPR boards 6, the iron board 5 and the two PPR boards 6 are arranged in close contact, the thickness of the iron board 5 is 3 mm, and the thickness of the two PPR boards 6 is 10 mm, which has good thermal insulation performance, and the PPR board is anti-corrosion, and the iron plate is set between two PPR boards, which plays a role of reinforcement and support, and has a good impact force.

[0014] The reaction tank 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com