Ceramic cutting device

A cutting device and ceramic technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of inconsistency in ceramic scale and customization, and inability to cut ceramics accurately, so as to increase sales and prevent deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

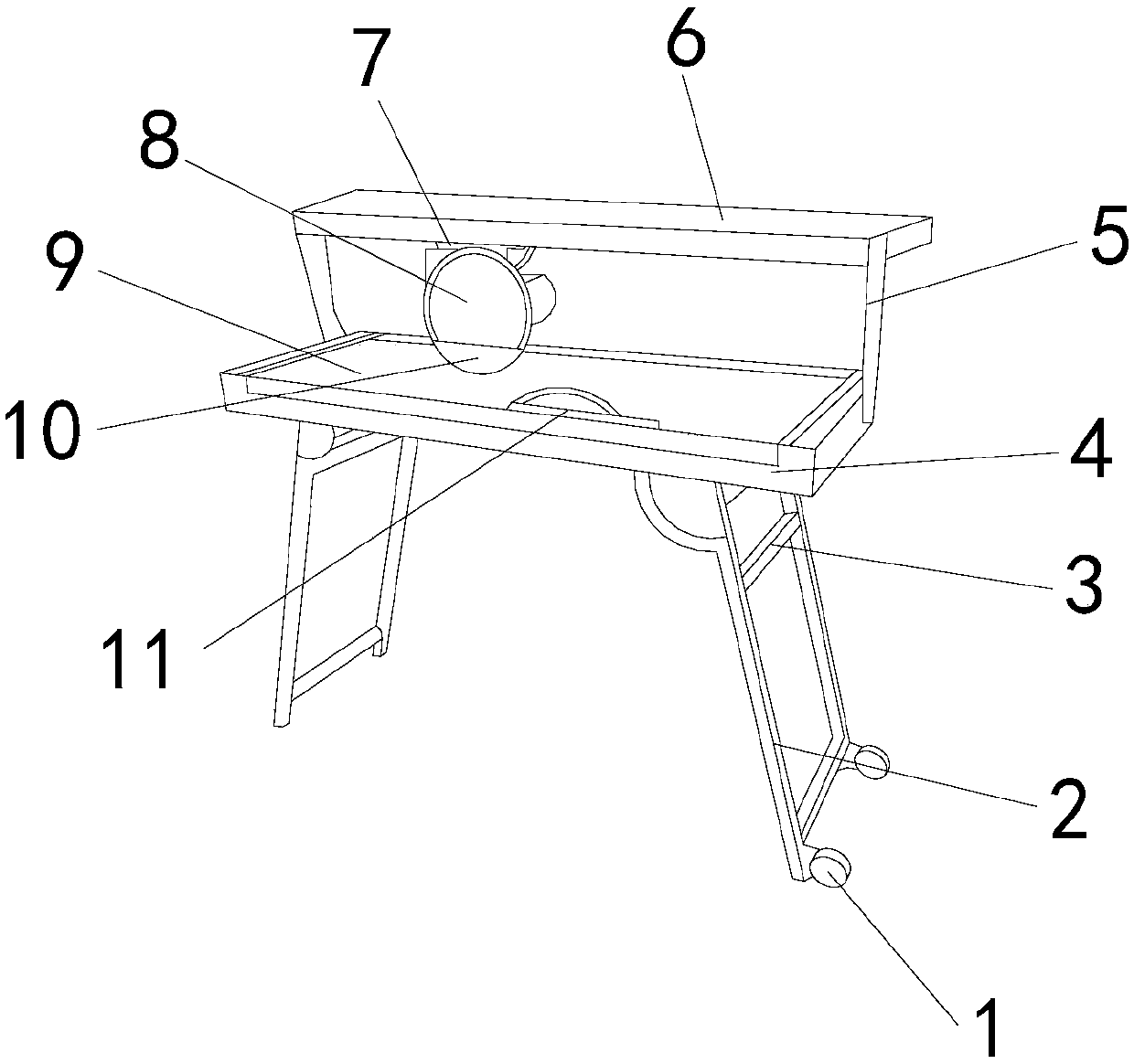

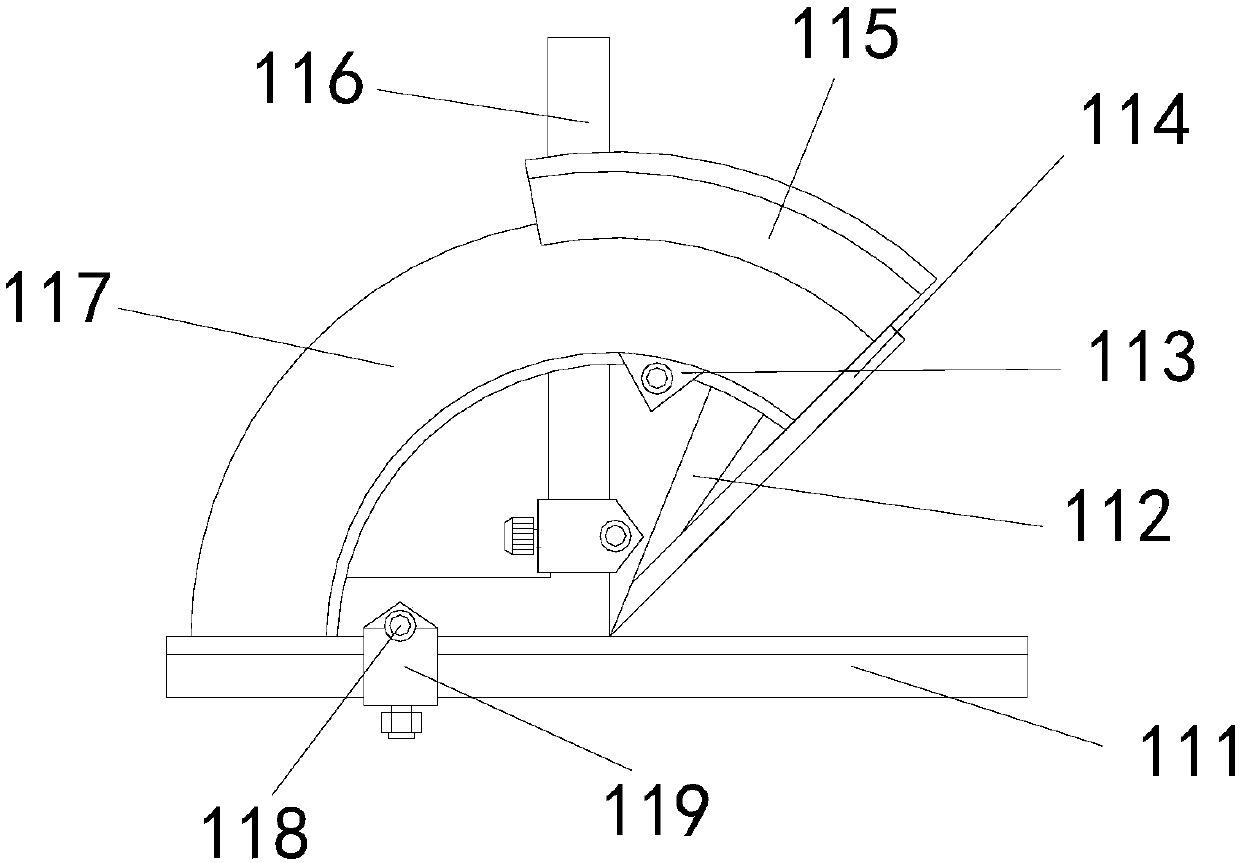

[0019] see Figure 1-Figure 2 , the present invention provides a technical solution: a ceramic cutting device, the structure of which includes a roller 1, an inclined support 2, a horizontal support 3, a fuselage 4, an iron support 5, a top cover 6, a motor 7, a protective cover 8, and a workbench 9, blade 10, measuring ruler 11, described fuselage 4 is cuboid structure, height is 5cm, length is 150cm, and width is 50cm, and described fuselage 4 is welded workbench 9, and workbench 9 is cuboid structure, described The motor 7 welds the oblique support 2, the oblique support 2 is a rectangular parallelepiped structure, the height is 90cm, the length is 4.5cm, and the width is 4.5cm. There are four of them and the equilateral size is the same. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com