Catalyst system composition for production of PET (polyethylene terephthalate) resin

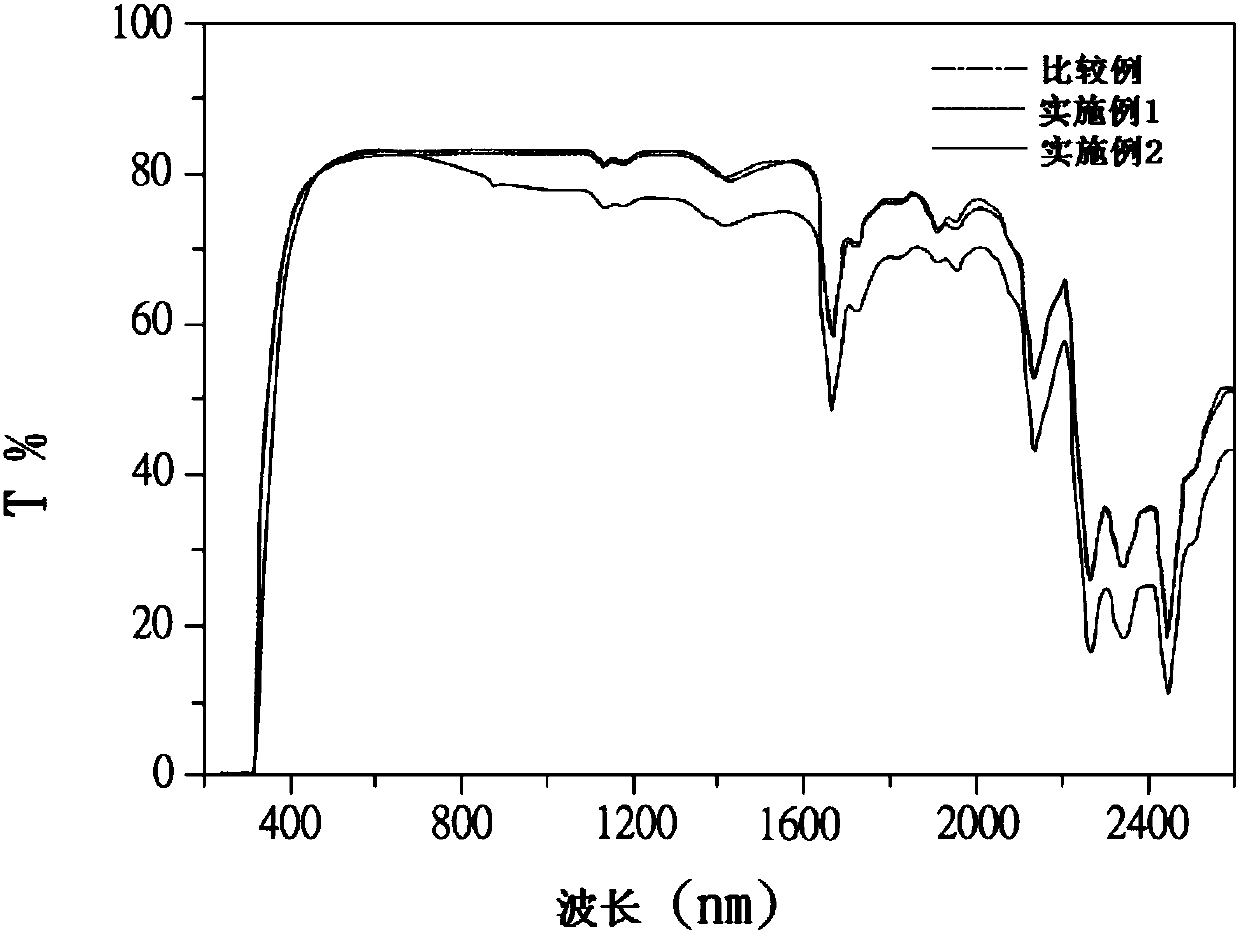

A catalyst and composition technology, applied in the field of catalyst system composition, can solve the problems of yellowish color of PET resin, long process time, slow solid-state polymerization rate, etc., and achieve the effect of improving yellowish color, shortening process time and increasing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

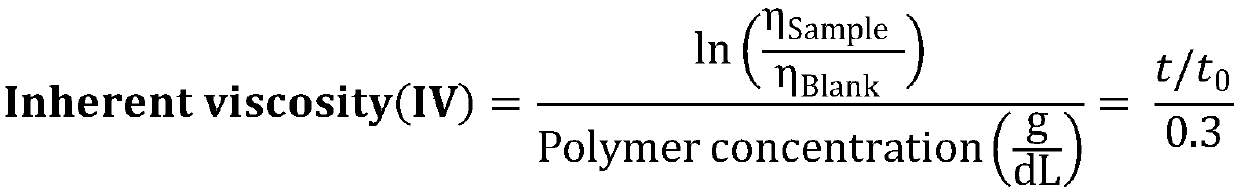

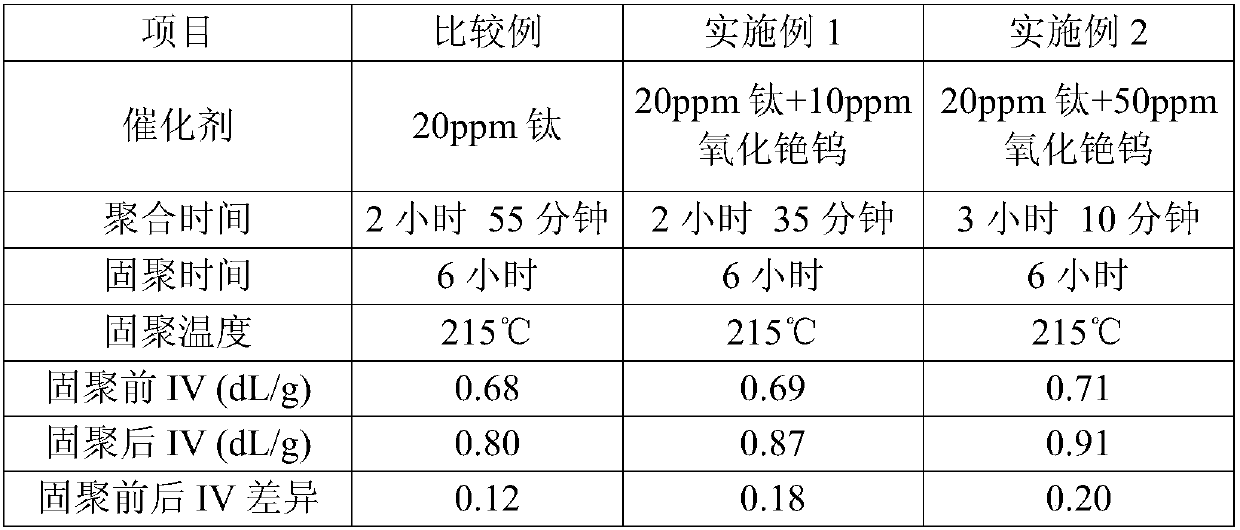

Embodiment 1

[0032] Weigh 400g of BHET monomer and 20g of ethylene glycol in the reactor, and then add 0.056g of TBT catalyst (titanium content is 20ppm of theoretical PET weight) and 0.084g of cesium tungsten oxide nano-dispersed liquid ( The cesium tungsten oxide content is 10ppm of the theoretical PET weight) catalyst system composition, and 0.03g phosphoric acid is added (the phosphorus content is 24.5ppm of the theoretical PET weight); the reaction temperature is 260℃, and the vacuum is gradually applied after 10 minutes of reaction Reduce to 60mmHg for about 30 minutes; then increase the temperature to 280°C to further reduce the vacuum to 1torr (approximately equivalent to 1mmHg), continue the reaction until the torque value displayed by the agitator reaches a fixed value, and then discharge. The subsequent solid-state polymerization steps are as follows. Weigh 50-100g of the polymerized PET product and place it in a vacuum high-temperature furnace. The reaction temperature will rise ...

Embodiment 2

[0034] Weigh 400g of BHET monomer and 20g of ethylene glycol in the reactor, and add 0.056g of TBT catalyst (titanium content is 20ppm of theoretical PET weight), 0.420g of cesium tungsten oxide nano-dispersed liquid ( The cesium tungsten oxide content is 50ppm of the theoretical PET weight) catalyst system composition, and 0.03g phosphoric acid is added (the phosphorus content is 24.5ppm of the theoretical PET weight); the reaction temperature is 260℃, and the vacuum is gradually applied after 10 minutes of reaction Reduce to 60mmHg for about 30 minutes; then increase the temperature to 280°C to further reduce the vacuum to 1torr (approximately equivalent to 1mmHg), continue the reaction until the torque value displayed by the agitator reaches a fixed value, and then discharge. The subsequent solid-state polymerization steps are as follows. Weigh 50-100g of the polymerized PET product and place it in a vacuum high-temperature furnace. The reaction temperature will rise from roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com