Polyoxymethylene resin composition and preparation method thereof

A polyoxymethylene resin and composition technology, applied in the field of polyoxymethylene resin composition and its preparation, can solve the problems of high appearance color requirements, low strength, low heat distortion temperature under load, etc., to achieve enhanced bonding and improved interface properties , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

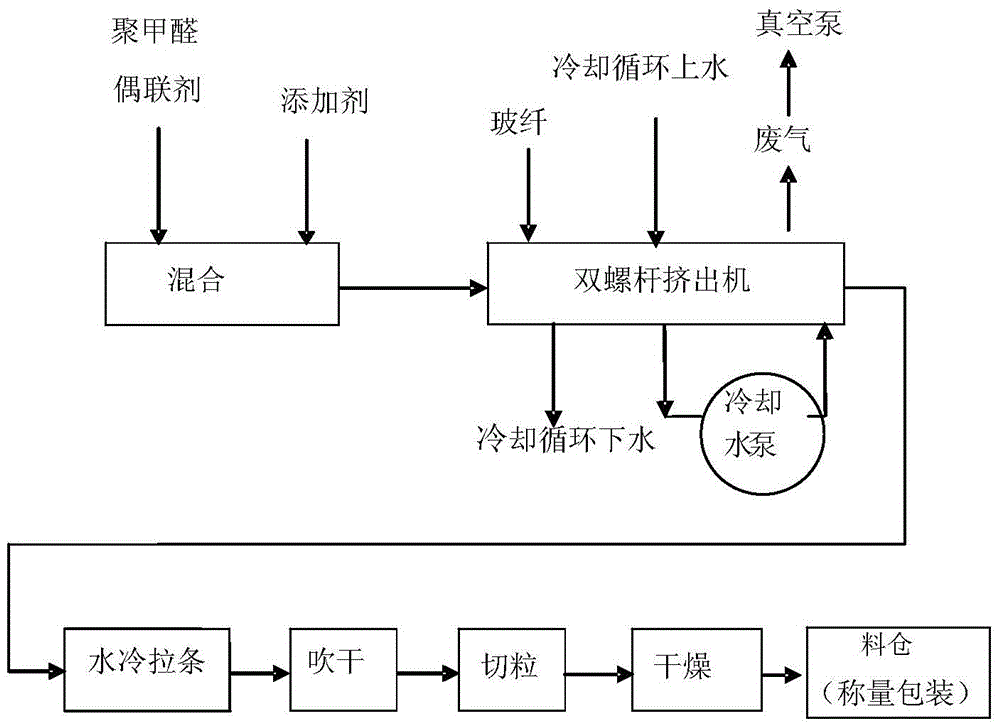

[0035]The present invention also provides a kind of preparation method of polyoxymethylene resin composition, comprising:

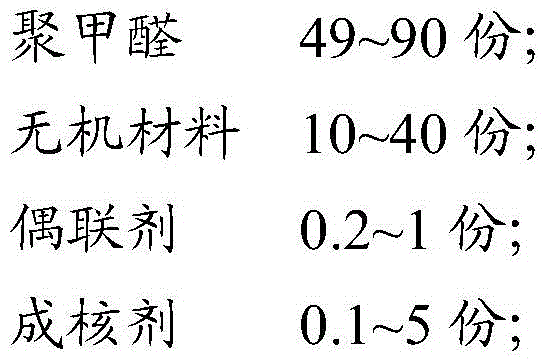

[0036] 1) Mix 49-90 parts by weight of polyoxymethylene, 10-40 parts by weight of inorganic materials, 0.2-1 part by weight of coupling agent and 0.1-5 parts by weight of nucleating agent, extrude and granulate to obtain granulated polyoxymethylene resin combination;

[0037] The coupling agent is 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 3-glycidyl etheroxypropylmethyltriethoxysilane, γ-glycidyl etheroxy Any two or more of propylpropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane and γ-aminopropyltriethoxysilane;

[0038] 2) drying the granulated polyoxymethylene resin composition to obtain a polyoxymethylene resin composition.

[0039] According to the present invention, 49-90 parts by weight of polyoxymethylene, 10-40 parts by weight of inorganic materials, 0.2-1 part by weight of coupling agent and 0.1-5 parts by weight of nucleating ag...

Embodiment 1

[0049] Polyoxymethylene (medium-viscosity polyoxymethylene M90, produced) 7.31kg, 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane (HK531) 7g, γ-glycidyl ether oxypropyl trimethyl Add 59.5 g of oxysilane (KH560) and 3.5 g of 3-glycidyloxypropylmethyltriethoxysilane (KH561) into a high-speed mixer and mix for 6 minutes to obtain a mixture material 1;

[0050] Add 80g of Ciba Antioxidant 245, 40g of melamine and 250g of slightly cross-linked polyoxymethylene into the mixed material 1 and mix at high speed for 6 minutes to obtain the mixed material 2;

[0051] Add the mixed material 2 to the main feeding hopper of the twin-screw extruder, and add 2.5kg of alkali-free chopped glass fiber 308A to the side feeding hopper at the same time. The temperature in zone 11 is 165-215°C, the machine head is 195°C, the screw speed of the main engine is 250rpm, and the speed of the side feeding screw is 75rpm, extruding and granulating to obtain a granulated polyoxymethylene resin composition

...

Embodiment 2~4

[0067]The preparation method of embodiment 2~4 is the same as embodiment 1, changes the amount that adds coupling agent, and the addition amount of coupling agent is respectively 40g, 60g and 80g, and other raw materials are composed identically: polyoxymethylene pellet 7.1kg, without Alkali chopped glass fiber 2.5Kg; slightly cross-linked polyoxymethylene copolymer 200g; melamine 40g; Ciba antioxidant 24580g;

[0068] Among them, the coupling agent, by mass percentage, consists of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane 15% (HK531), γ-glycidyl etheroxypropyl trimethoxy Silane (KH560) 85% and γ-methacryloxypropyl trimethoxysilane (KH570) 5% mixed.

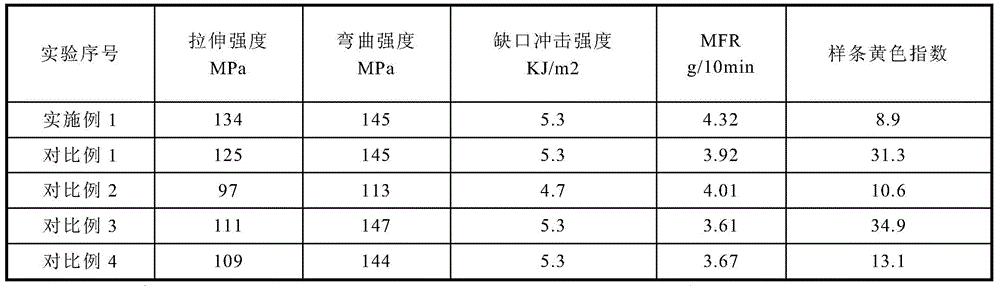

[0069] The performance test of the polyoxymethylene resin composition prepared in Examples 2-4 is carried out, and the results are shown in Table 4, and Table 4 is the performance test result of the polyoxymethylene resin composition provided by the implementation of 2-4 of the present invention;

[0070] Table 4 is the perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com