Label production equipment and fast production method thereof

A technology for production equipment and labels, applied to label production equipment and the field of rapid production, can solve problems such as easy deviation, product quality, consistency, difficulty in controlling the yield rate, unfavorable production efficiency and quality, etc. Accuracy, avoid excessive hard force, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

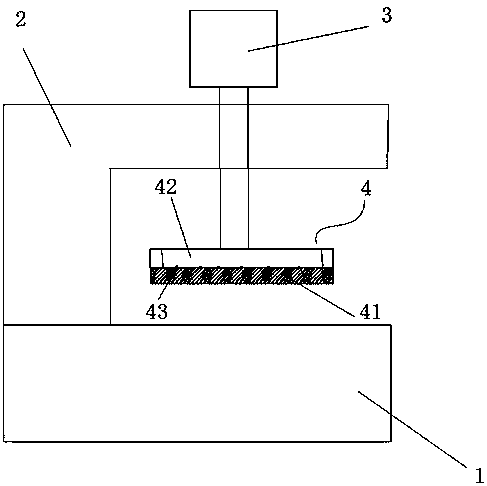

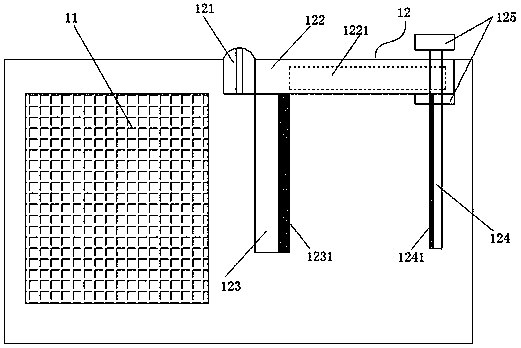

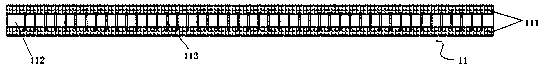

[0027] A label production equipment, comprising a base 1, a support part 2, a drive mechanism 3, the support part 2 is arranged above the base 1, the drive mechanism 3 is arranged on the support part 2, it is characterized in that the The driving mechanism 3 is connected with a processing part 4, the base 1 is provided with a positioning part 11 and a positioning mechanism 12; the positioning mechanism 12 includes a hinge structure 121, a movable arm 122, a fixed rod 123, a movable rod 124, and a locking mechanism 125 , the hinge structure 121 is connected to the movable arm 122, the movable arm 122 is provided with a hollow portion 1221, the movable rod 124 passes through the hollow portion 1221, and the movable rod 124 is connected to the movable arm 122. Locking mechanisms 125 are arranged symmetrically on both sides, and the fixed rod 123 is fixedly connected to the movable arm 122 .

[0028] Further, the fixed rod 123 is provided with a first card slot 1231 , the movable ...

Embodiment 2

[0043] A label production equipment, comprising a base 1, a support part 2, a drive mechanism 3, the support part 2 is arranged above the base 1, the drive mechanism 3 is arranged on the support part 2, it is characterized in that the The driving mechanism 3 is connected with a processing part 4, the base 1 is provided with a positioning part 11 and a positioning mechanism 12; the positioning mechanism 12 includes a hinge structure 121, a movable arm 122, a fixed rod 123, a movable rod 124, and a locking mechanism 125 , the hinge structure 121 is connected to the movable arm 122, the movable arm 122 is provided with a hollow portion 1221, the movable rod 124 passes through the hollow portion 1221, and the movable rod 124 is connected to the movable arm 122. Locking mechanisms 125 are arranged symmetrically on both sides, and the fixed rod 123 is fixedly connected to the movable arm 122 .

[0044] Further, the fixed rod 123 is provided with a first card slot 1231 , the movable ...

Embodiment 3

[0058] A label production equipment, comprising a base 1, a support part 2, a drive mechanism 3, the support part 2 is arranged above the base 1, the drive mechanism 3 is arranged on the support part 2, it is characterized in that the The driving mechanism 3 is connected with a processing part 4, the base 1 is provided with a positioning part 11 and a positioning mechanism 12; the positioning mechanism 12 includes a hinge structure 121, a movable arm 122, a fixed rod 123, a movable rod 124, and a locking mechanism 125 , the hinge structure 121 is connected to the movable arm 122, the movable arm 122 is provided with a hollow portion 1221, the movable rod 124 passes through the hollow portion 1221, and the movable rod 124 is connected to the movable arm 122. Locking mechanisms 125 are arranged symmetrically on both sides, and the fixed rod 123 is fixedly connected to the movable arm 122 .

[0059] Further, the fixed rod 123 is provided with a first card slot 1231 , the movable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com