Washing machine vibration reducing assembly and washing machine

A vibration damping component and washing machine technology, which is applied in the field of washing machines, can solve the problems of inability to reduce the vibration of the outer tub, poor air sealing, and failure of vibration damping components, etc., achieve quiet and stable dehydration start and operation, reduce shaking and swing, and facilitate production The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

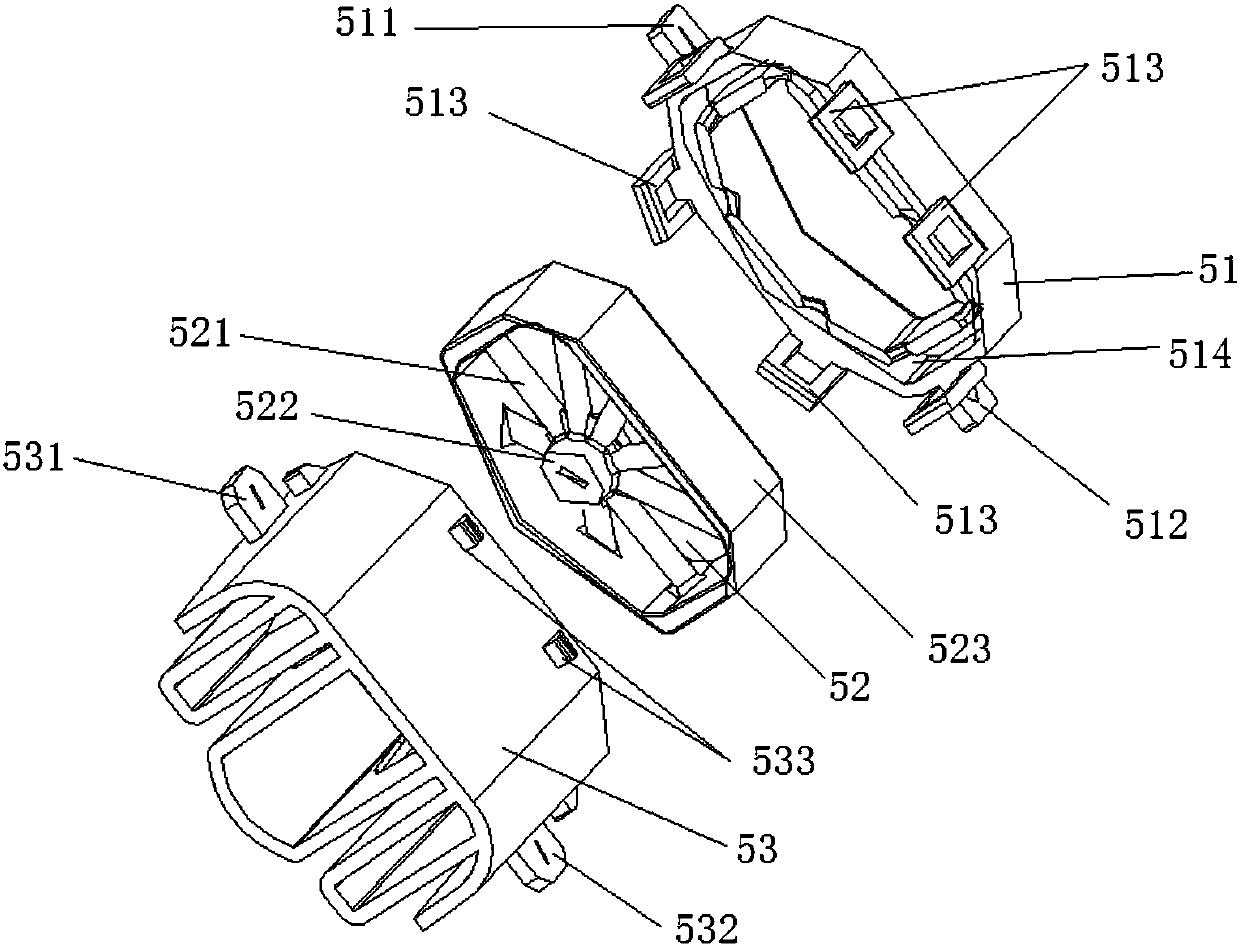

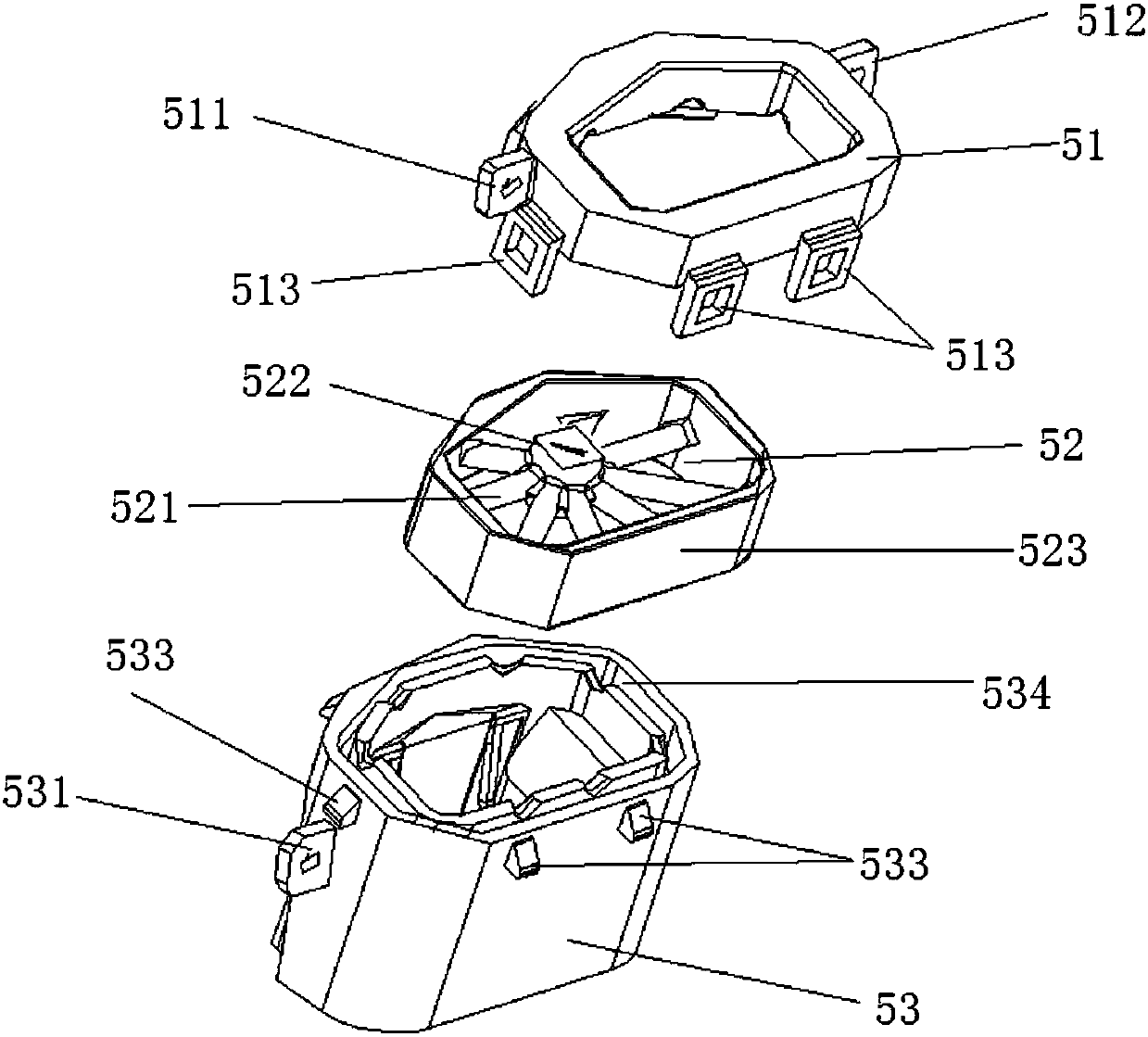

[0036] Such as figure 2 and image 3 As shown, the elastic rubber 52 described in this embodiment includes a body 523, an elastic strip 521 and a collar 522, the body 523 is connected to the collar 522 through the elastic strip 521, and the collar 522 is arranged in the middle of the elastic rubber 52 position, the collar 522 is connected with a plurality of elastic strips 521, and is arranged in the middle. When the boom 1 vibrates, the force can be evenly distributed to each elastic strip 521, reducing the vibration in all directions. The collar 522 It is a hollow cylinder arranged in cooperation with the suspender 1. The suspender 1 passes through the hollow position of the collar 522. In this embodiment, the body 523, the elastic strip 521 and the collar 522 in the elastic rubber 52 are integrally formed. design, which can ensure that when the boom 1 vibrates in all directions, the degree of deformation of the elastic rubber 52 is not large, and has a good damping effect...

Embodiment 2

[0038] Such as Figure 1-4 As shown, in this embodiment, the elastic strip 521 and the collar 522 are on the same plane, and the plane is located in the middle of the elastic rubber 52. When the middle of the elastic strip 521 and the collar 522 are on the same plane, The force of the suspension rod 1 on the elastic rubber 52 is more evenly distributed, and the vibration effect of the washing machine is the best at this time. In this embodiment, the elastic strip 521 and the collar 522 may not be on the same plane.

[0039] In a preferred technical solution, the elastic strip 521, the collar 522 and the body 523 are integrally formed to form the elastic rubber 52, which increases the stability of the elastic rubber 52, is not easily deformed, and has a better vibration damping effect.

[0040] In a preferred technical solution, the elastic strips 521 on the elastic rubber 52 are arranged in a radial shape, and the elastic strips 521 are uniformly distributed around the collar ...

Embodiment 3

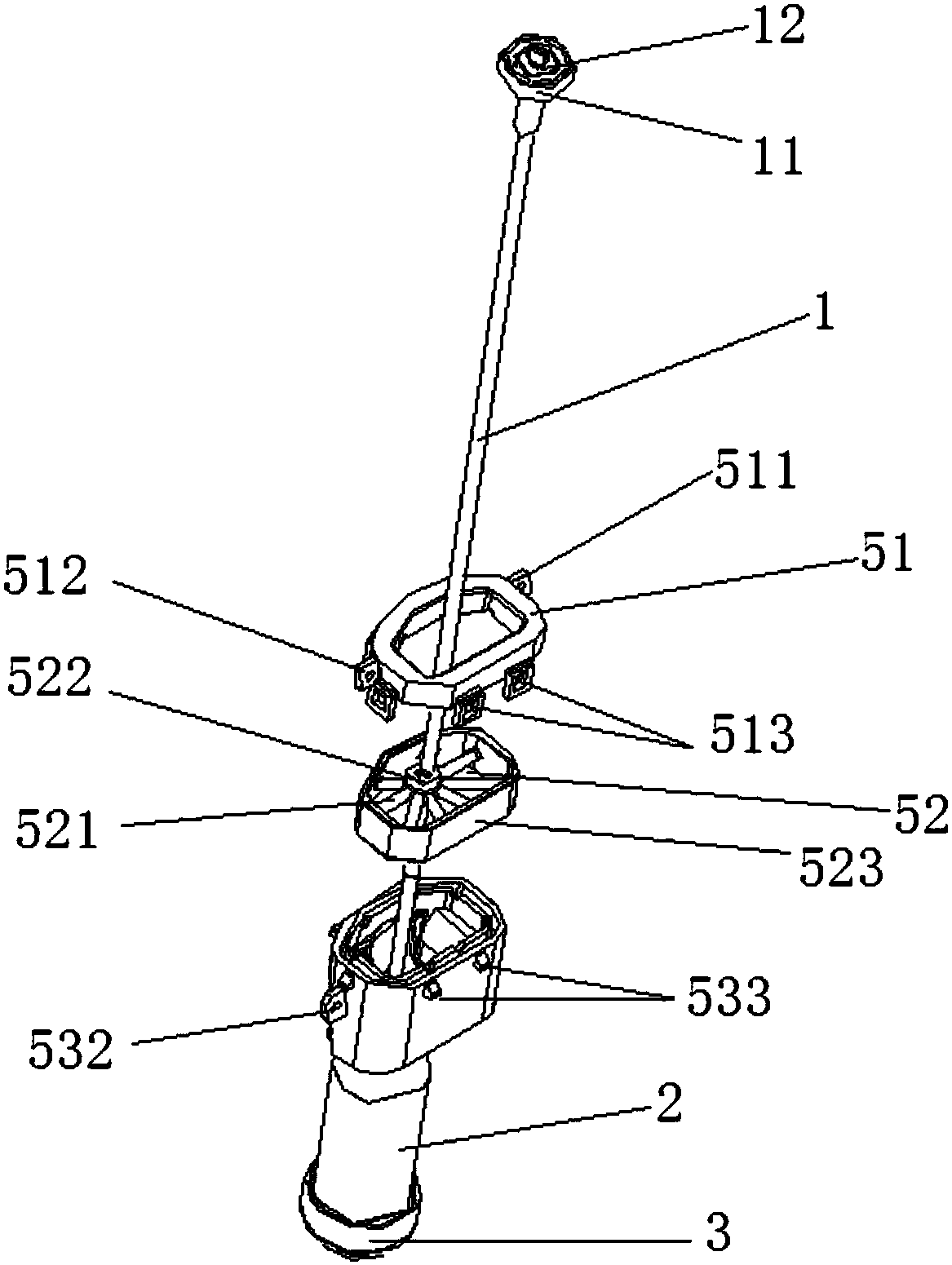

[0042] The upper end of the boom 1 described in this embodiment is provided with a boom seat 11, and a gasket 12 is arranged inside the boom seat 11, and the boom 1 is connected with the corner reinforcement plate 7 of the washing machine through the boom seat 11 Fixed on the box body 8, the sleeve part 2 in this embodiment is provided with a damping spring, the sleeve part 2 is arranged on the outer barrel suspension seat 4, and the spring setting in the sleeve part 2 adopts the prior art Design, when the washing machine is running, the outer tub 6 will vibrate in different degrees along with the washing and dehydration, compress the spring, and the expansion and contraction of the spring fluctuate randomly with the vibration, which has a good resistance to the aggravation of vibration, and realizes load-bearing and For the function of damping, the damping assembly of the present implementation utilizes the combined effect of the sleeve part 2 and the damping ring 5 of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com