Long-distance steel rail damage detector

A damage detection, long-distance technology, applied to instruments, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, analyze materials, etc., can solve the problem of inability to detect rail status, inability to detect rail fractures and damages in time, inability to monitor on rails for a long time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

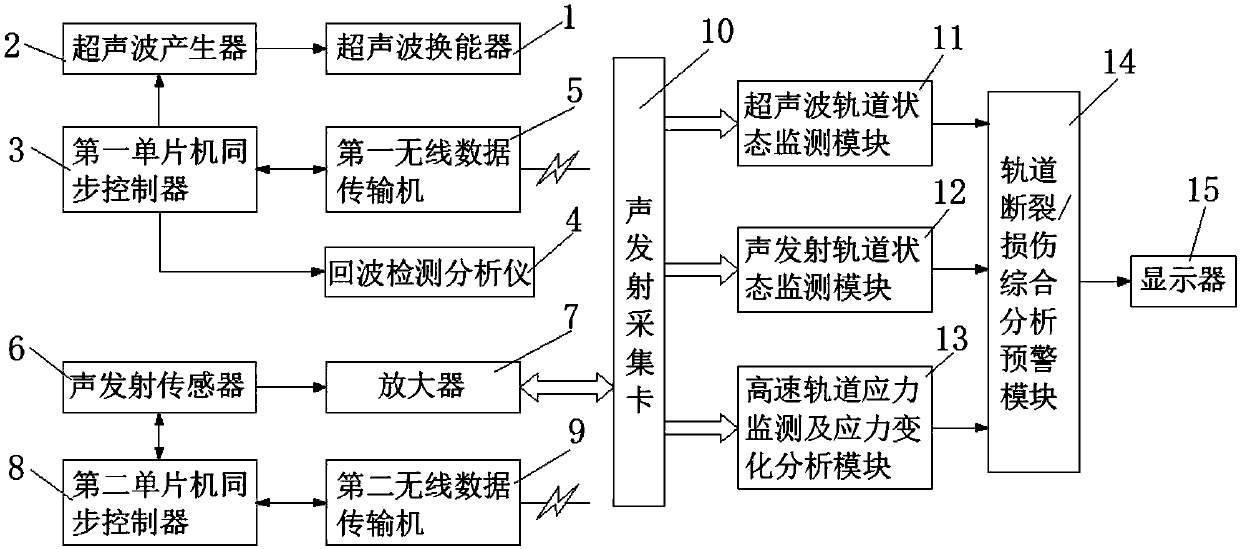

[0031] The invention provides a long-distance rail damage detector, specifically as image 3 As shown, it includes a synchronous sound wave generating module, a sound wave receiving module and an ultrasonic analysis module;

[0032] The synchronous sound wave generation module comprises ultrasonic transducer 1, ultrasonic generator 2, the first single-chip synchronous controller 3, echo detection analyzer 4 and the first wireless data transmission machine 5, the signal input end of ultrasonic transducer 1 and ultrasonic wave The signal output end of generator 2 is connected, and the signal signal input end of ultrasonic generator 2 is connected with the first signal output end of the first single-chip microcomputer synchronous controller 3, and the second signal output end of the first single-chip microcomputer synchronous control circuit 3 is connected with the echo The signal input terminal of the detection analyzer 4 is connected, the signal output terminal of the echo dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com