Array substrate

An array substrate and glass substrate technology, applied in the display field, can solve problems such as limited bonding strength, and achieve the effect of improving surface wear resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

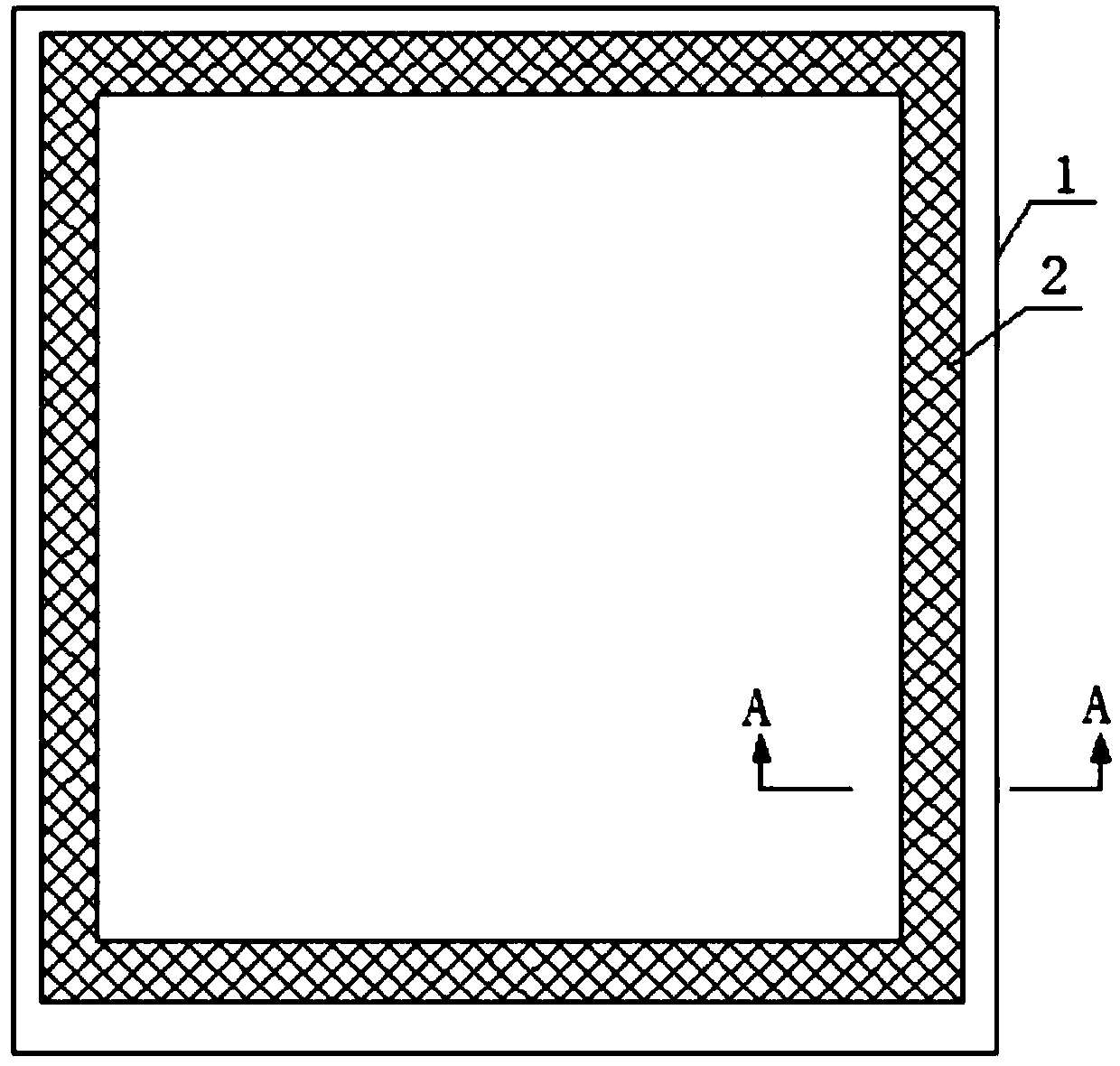

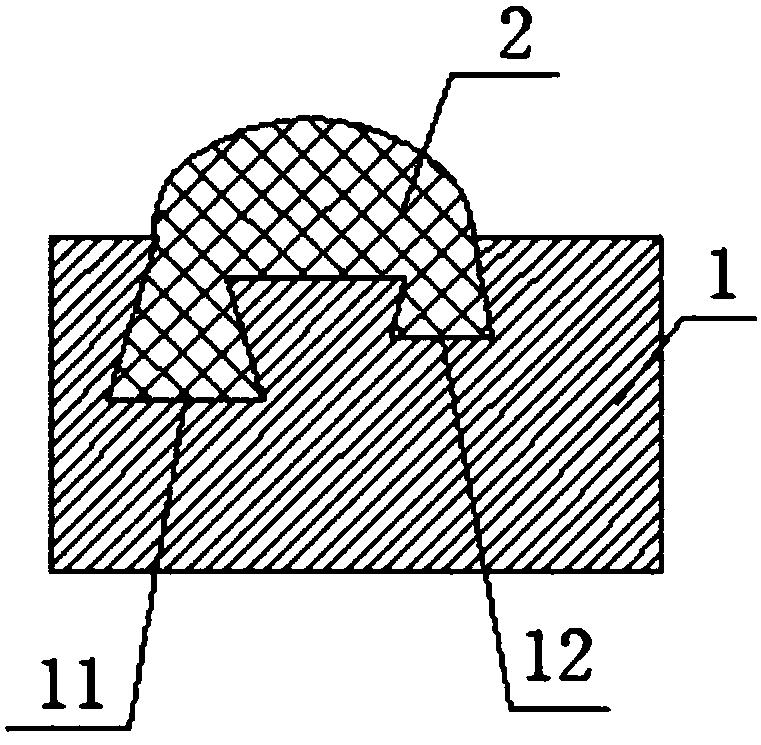

[0029] See Figure 1 to Figure 2 , The present invention provides an array substrate, including: a glass substrate 1 and a sealant 2 coated on the glass substrate 1; the glass substrate 1 is provided with a first frame-shaped groove body 11 and a second frame-shaped groove Body 12; The first frame-shaped tank body 11 is located inside the second frame-shaped tank body 12; the cross-sections of the first frame-shaped tank body 11 and the second frame-shaped tank body 12 are trapezoidal, The trapezoidal lower bottoms of the first frame-shaped tank body 11 and the second frame-shaped tank body 12 are located below, and a connecting portion is provided above the upper bottom area. The first frame-shaped tank body 11 and the second frame The upper part of the shaped tank body 12 is communicated through the connecting portion; the sealant 2 is coated on the glass substrate 1, and the sealant 2 is filled in the first frame-shaped tank body 11 and the second frame-shaped tank The insi...

Embodiment 2

[0032] A method for manufacturing a glass substrate of an array substrate, the steps are as follows:

[0033] 1), structure and separate processing

[0034] The glass substrate is provided with a first frame-shaped tank body and a second frame-shaped tank body; the first frame-shaped tank body is located inside the second frame-shaped tank body; the cross section of the first frame-shaped tank body and the second frame-shaped tank body Both are trapezoidal, the trapezoidal bottoms of the first frame-shaped tank body and the second frame-shaped tank body are located below, and the sealant is filled in the first frame-shaped tank body, the second frame-shaped tank body and the inside of the communicating part;

[0035] The glass substrate is made by the float glass manufacturing process; the frame-shaped tank is formed by cutting ruby;

[0036] 2), pre-treatment

[0037] Soak the cut glass substrate in the bath for at least 5 minutes, take it out and rinse it immediately, and then dry it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com