Polishing device and process for ceramic tile with polishing grinding heads arranged in multiple rows

A polishing device and grinding head technology, applied in the ceramic tile field, can solve problems such as inability to eliminate pans, and achieve the effects of improving effective coverage, improving production efficiency and product quality, and reducing wear and tear of abrasives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

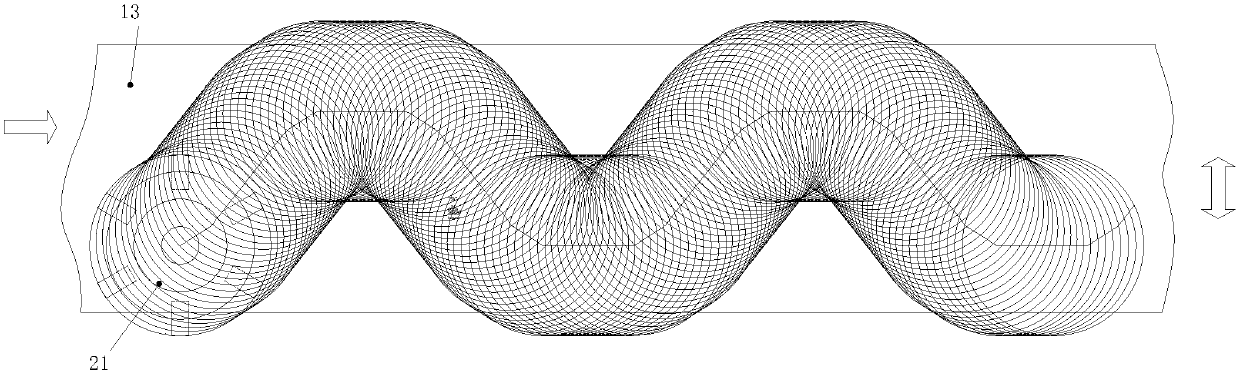

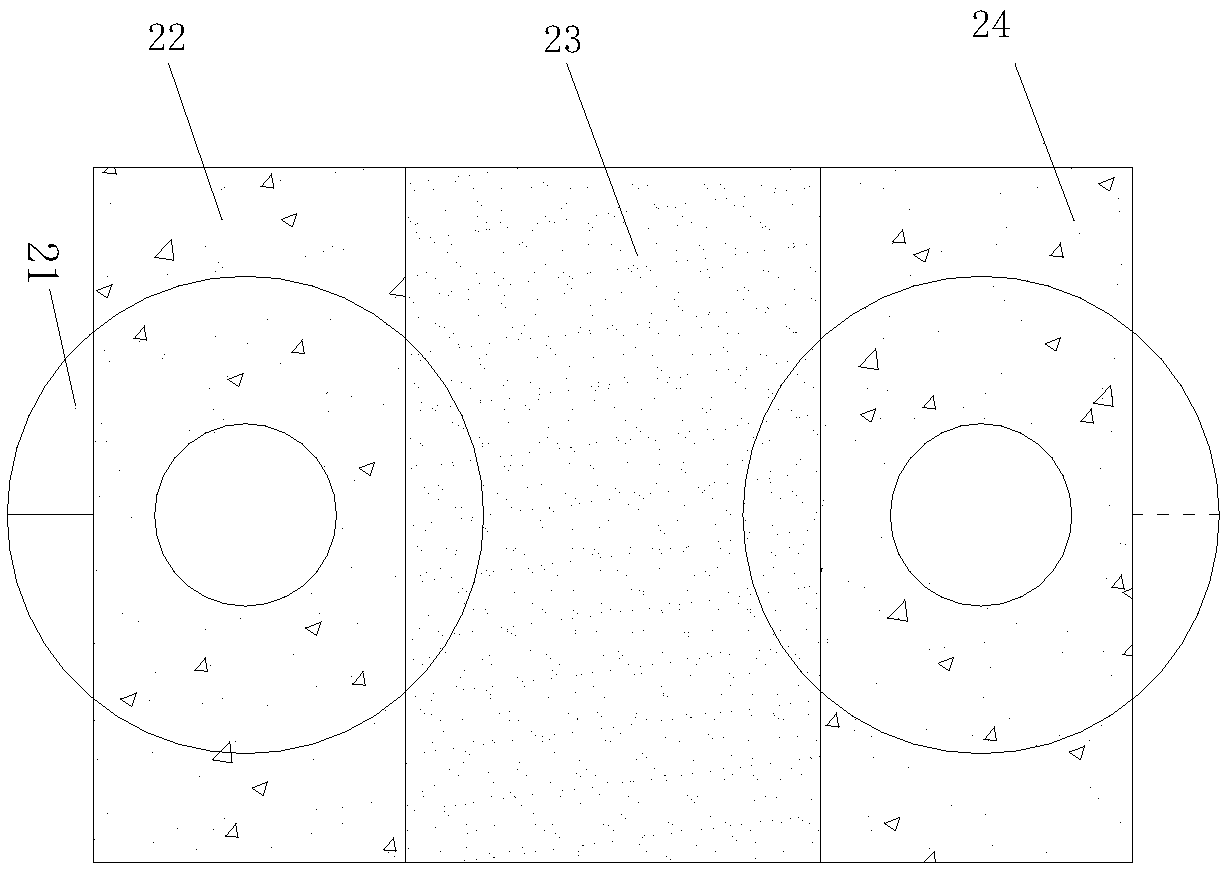

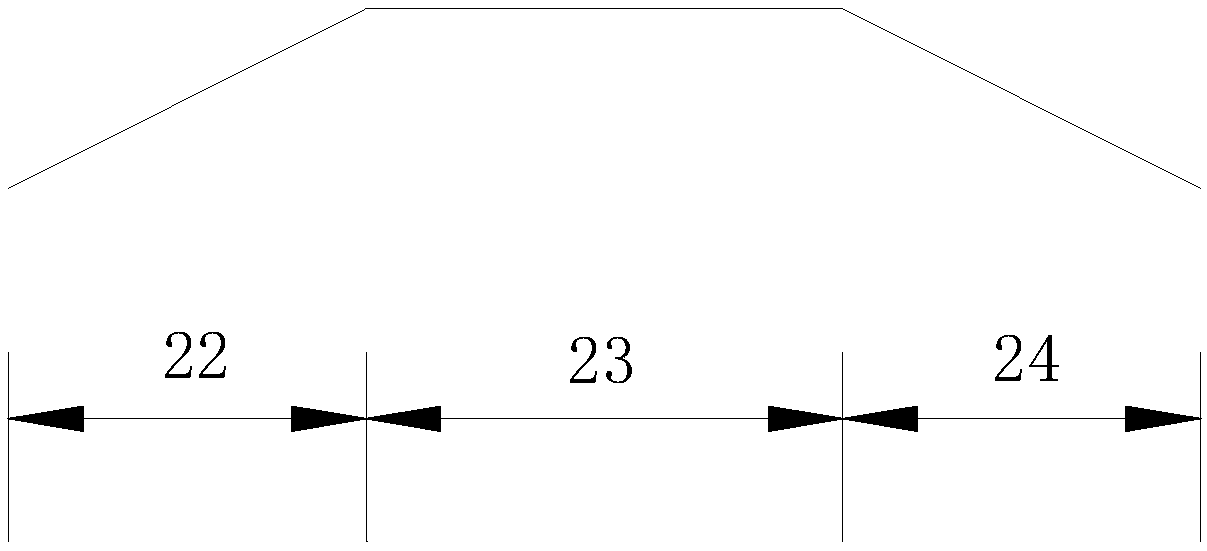

[0040]A polishing device with tiles arranged in multiple rows of polishing grinding heads, including a tile feeding system, the tile feeding system is installed on the frame 3, the tile feeding system drives the tiles 13 to feed along the length direction of the tiles 13, and the polishing device also includes The beam system and the grinding head system, the beam system is installed on the frame 13, the beam system includes at least two beams 10 (11) arranged in parallel along the tile feed direction, the grinding head system is at least two groups, and each group of grinding head systems is installed On a beam 10 (11), several grinding heads 21 are arranged on the grinding head system for polishing ceramic tiles 13. The number of beams 10 (11) is greater than the number of groups of grinding head systems, and the grinding head systems are arranged on adjacent beams 10 (11). According to the tiles of different specifications and sizes, the number of groups of the grinding hea...

Embodiment 2

[0049] Such as Figure 10 and 11 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. Grinding head 21 and grinding head driving motor 25 are all installed on the crossbeam 10 (11), and the direction that grinding head driving motor 25 is installed is vertical to the direction that tile 13 is fed, that is, the grinding head driving motor 25 and grinding head 21 are connected. Direction is perpendicular to the feeding direction of ceramic tile 13, and the grinding head driving motor 25 is protruded outside the crossbeam 10 (11) and installed, and the length of the crossbeam 10 (11) can be reduced by setting the grinding head driving motor 25 like this.

[0050] Another object of the present invention is to provide a polishing process for ceramic tiles arranged in multiple rows of polishing grinding heads, comprising the steps of:

[0051] (1). The processing area on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com