Multifunctional cutting blade

A cutting disc, multi-functional technology, applied in the field of multi-functional cutting discs, can solve the problems of diamond cutting discs such as loud noise, affecting work and physical and mental health, and affecting the normal life of others, and achieves long service life, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

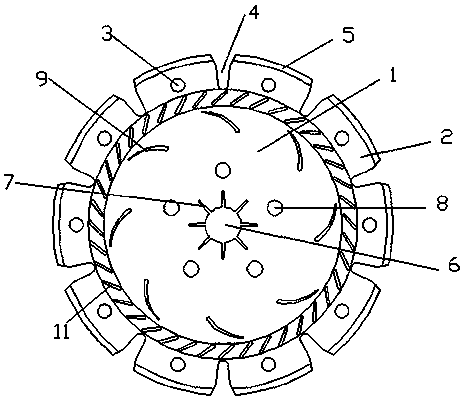

[0012] Such as figure 1 Shown is a schematic diagram of the overall structure of the present invention, a multifunctional cutting blade, including a saw blade body 1 and saw teeth 2, the saw blade body 1 is surrounded by a circle of saw teeth 2, and a circular noise reduction hole 3 is provided on the saw teeth 2 , between the sawtooth 2 is provided with a chip removal groove 4, the sawtooth 2 is provided with a hard alloy cutter head 5, the center of the saw blade body 1 is provided with a central hole 6, and the surrounding of the central hole 6 is provided with divergent strip grooves 7 , the strip groove 7 communicates with the central hole 6, the saw blade body 1 is provided with a transmission hole 8 and a noi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap