Flotation built-in ceramic membrane water purification system and method

A ceramic membrane and water purification technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage treatment, etc., can solve problems such as limited removal efficiency and threats to the health of urban residents, and achieve short implementation period, The effect of saving equipment investment, saving space and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A water purification method with a built-in ceramic membrane in air flotation, comprising the following steps:

[0028] 1) Use the above-mentioned air flotation built-in ceramic membrane water purification system;

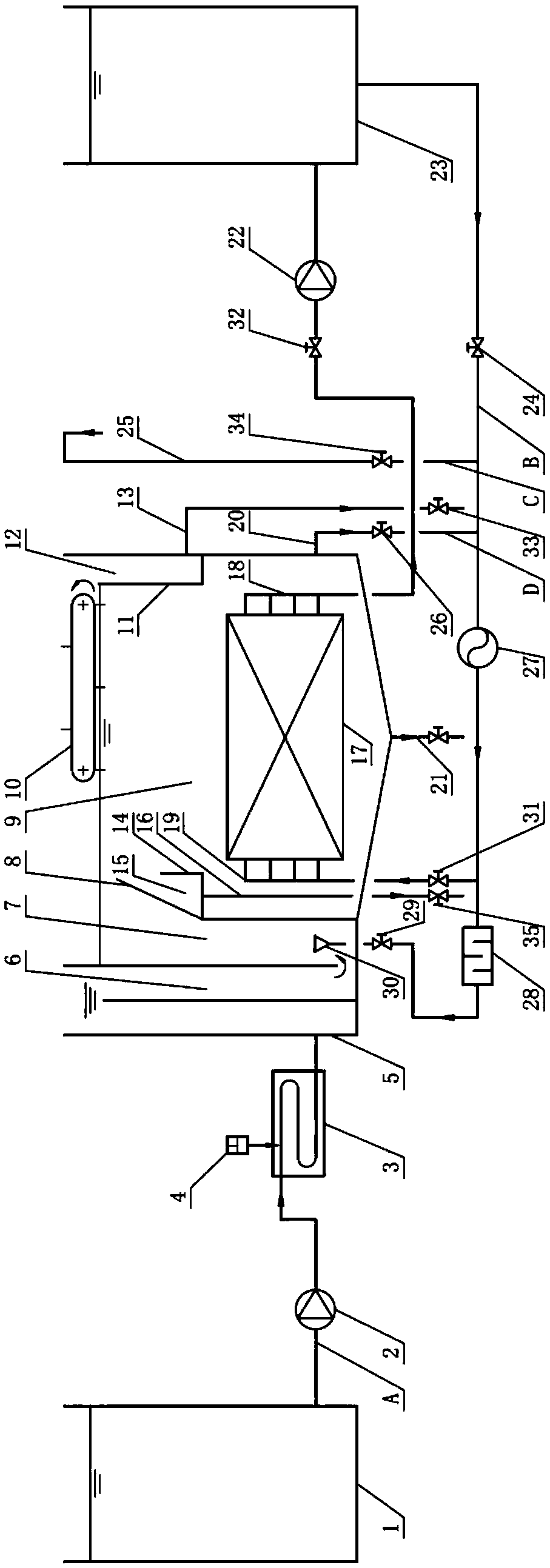

[0029] 2) Filtration stage: the effluent A of the raw water tank 1 is pressurized by the raw water pump 2 and enters the tubular mixer 3, mixed with the coagulant flowing out of the dosing device 4, and then enters the flocculation zone 6 in the air flotation tank 5 for flocculation and maturation; After the water flows out from the bottom of the flocculation zone 6, it enters the reaction zone 7 after contacting the dissolved air return water sprayed from the nozzle 30, and then enters the separation zone 9 through the baffle plate 8; Primary separation, the scum in the upper part of the separation area 9 is scraped by the slag scraper 10, after crossing the high overflow weir 11, it enters the slag discharge tank 12, and then is discharged from the scum di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap