Refined mixed aromatic narrow fraction separation method and device

A technology for mixing aromatic hydrocarbons and rectifying separation, which is applied in distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc. The effect of lower production costs and greater operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

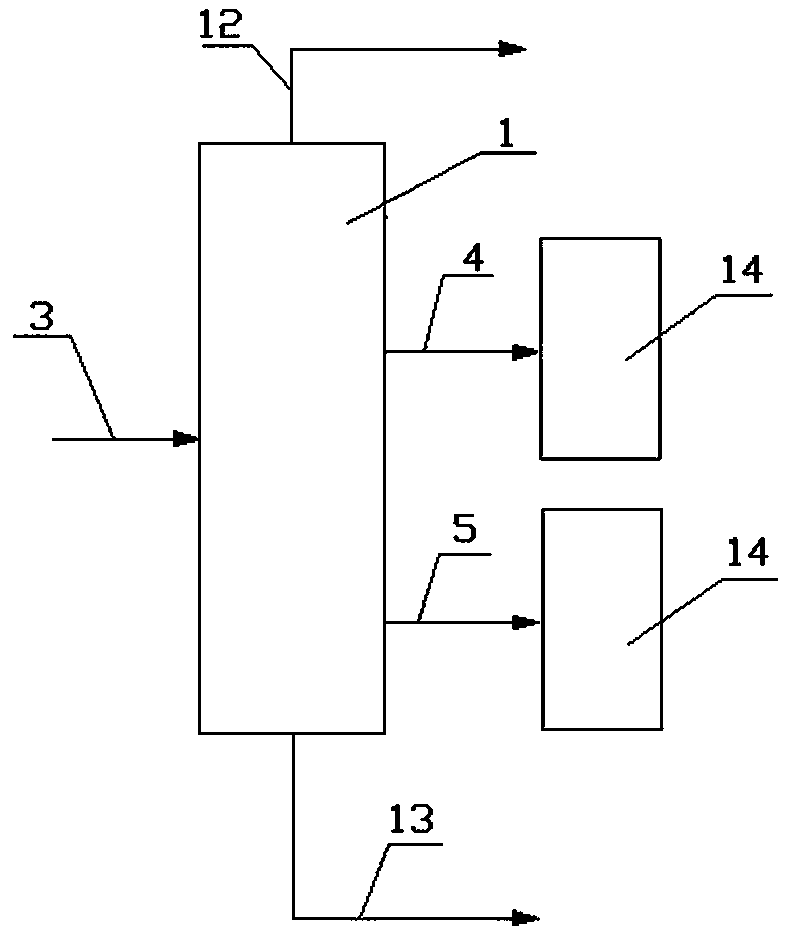

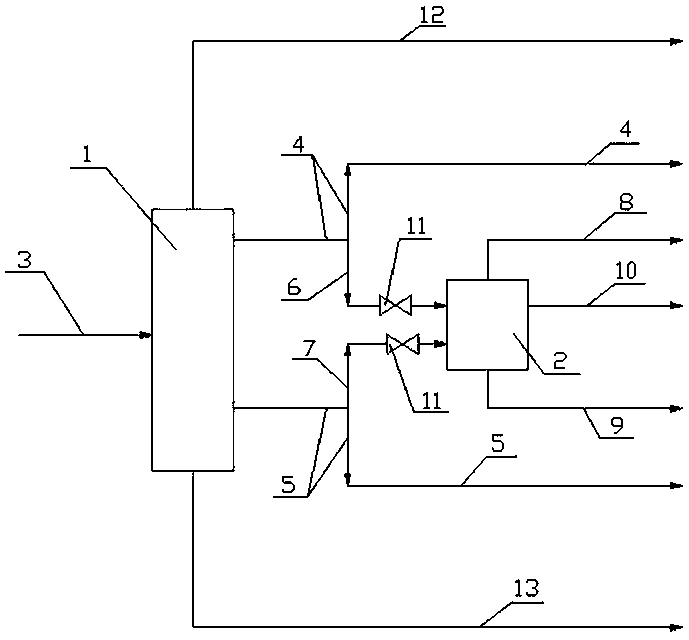

[0024] Embodiment 1, as attached figure 2As shown, the method for refining the narrow fraction separation of mixed aromatics is carried out according to the following steps: the first step, a narrow fraction separation tower 2 is connected after the mixed aromatics separation tower 1; the second step, the refined mixed aromatics enters the mixed aromatics Carry out rectification separation of mixed xylenes, mixed trimethylbenzenes, mixed tetramethylbenzenes and oil slurry in the separation tower 1, after rectification separation, discharge the mixed xylenes from the top of the mixed aromatics separation tower 1, and discharge the mixed xylenes from the bottom of the mixed aromatics separation tower 1 The oil slurry is discharged, and the mixed trimethylbenzenes and mixed tetramethylbenzenes are respectively discharged from the side line of the mixed aromatics separation tower 1; in the third step, when the mixed trimethylbenzenes need to be further separated, the mixed trimeth...

Embodiment 2

[0026] Embodiment 2, as the optimization of above-mentioned embodiment, according to needs, narrow fraction separation tower 2 is conventional plate rectification tower, and 60 trays are arranged in conventional plate rectification tower, in conventional plate rectification tower, from bottom to bottom And the position of the 40th tray on the top is the side draw position of 1# narrow cut and 3# narrow cut.

Embodiment 3

[0027] Example 3, as an optimization of Example 1, as needed, in the first step, the top temperature of the mixed aromatics separation tower 1 is 145°C to 185°C, the top pressure is 0.08MPa to 0.1MPa, and the bottom temperature is 214 °C to 254 °C, the pressure at the bottom of the tower is 0.11MPa to 0.13MPa, and the reflux ratio is 3 to 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com