A kind of bromine/antimony flame-retardant reinforced PBT composite material and preparation method thereof

A composite material and PBT resin technology, applied in bromine/antimony flame-retardant reinforced PBT composite material and its preparation field, can solve problems such as blurring, insufficient whiteness, and reduced laser marking performance of PBT materials, etc., to achieve contrast improvement and excellent Effect of Mechanical Properties and Flame Retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

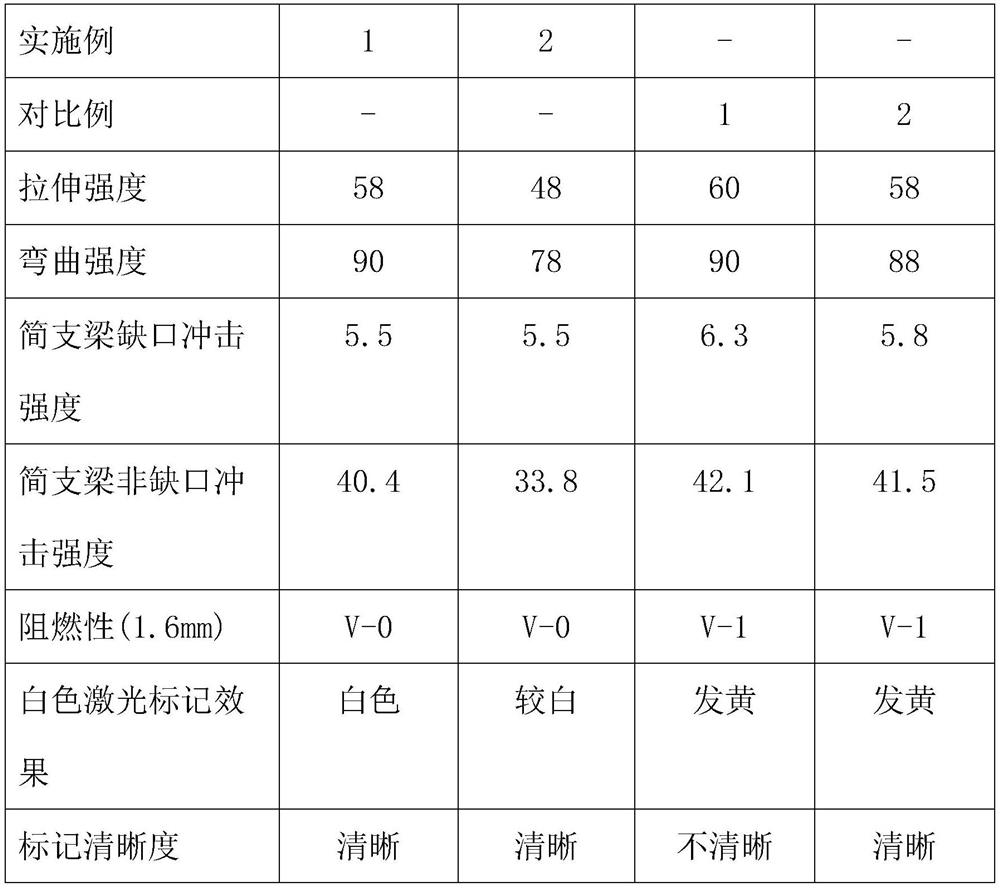

Examples

Embodiment 1

[0050] 100 parts by weight of PBT TH6100 dried at 120°C for 4 hours, 16 parts by weight of CR-225K, 4 parts by weight of antimony trioxide, 2 parts by weight of LaserAT-8733, and 12 parts by weight of self-made white laser marking masterbatch , Carbon black M800 weight part is 1, 1010 weight part is 0.2, 168 weight part is 0.4, mixes uniformly at room temperature, and pelletizes by twin-screw extruder. The processing technology is: the speed of the main engine is 200rpm, the temperature of the first stage is 200°C, the temperature of the second stage is 220°C, the temperature of the third stage is 230°C, the temperature of the fourth stage is 230°C, the temperature of the fifth stage is 240°C, and the temperature of the sixth stage is 240°C.

Embodiment 2

[0052] 100 parts by weight of PBT TH6100 dried at 120°C for 4 hours, 16 parts by weight of CR-225K, 4 parts by weight of antimony trioxide, and 2 parts by weight of LaserAT-8733, self-made white laser marking masterbatch (white laser marking Auxiliaries are XAP-03 and A11295) 12 parts by weight, carbon black M800 parts by weight 1, 1010 parts by weight 0.2, 168 parts by weight 0.4, mixed uniformly at room temperature, and granulated by a twin-screw extruder. The processing technology is: the speed of the main engine is 200rpm, the temperature of the first stage is 200°C, the temperature of the second stage is 220°C, the temperature of the third stage is 230°C, the temperature of the fourth stage is 230°C, the temperature of the fifth stage is 240°C, and the temperature of the sixth stage is 240°C.

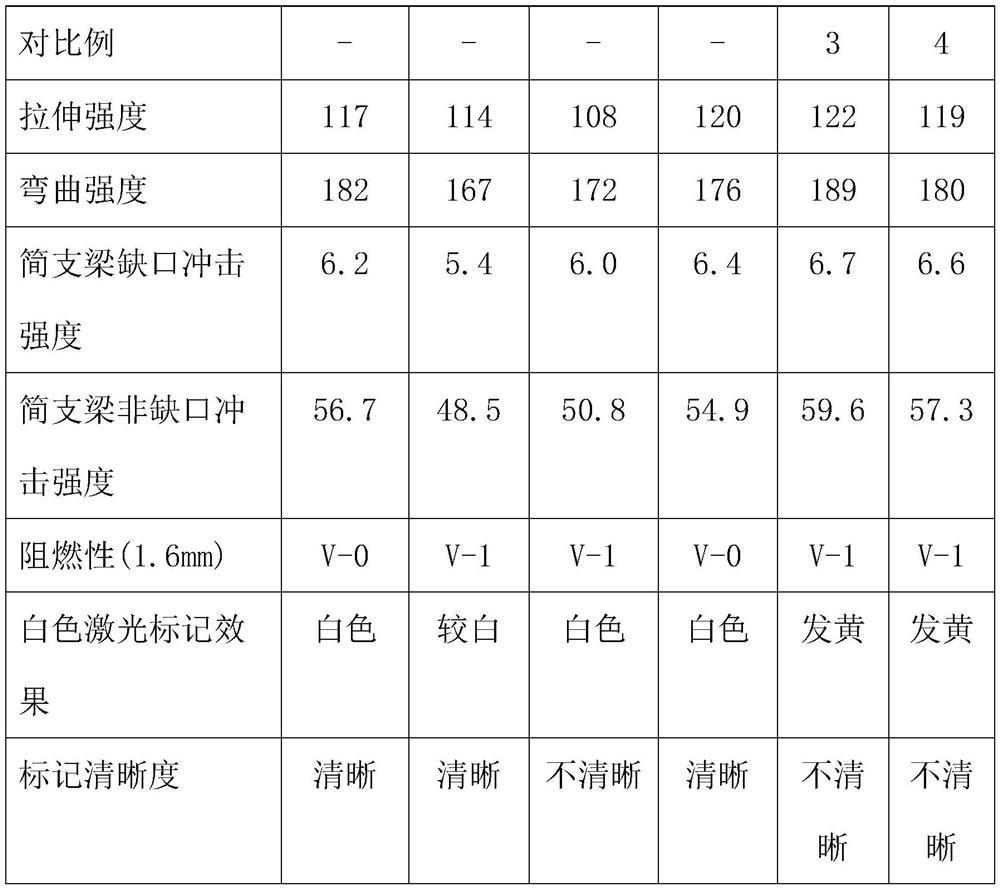

Embodiment 3

[0054] 50 parts by weight of PBT TH6100, 50 parts by weight of PBT TH6082, 16 parts by weight of decabromodiphenylethane, 4 parts by weight of antimony trioxide, and 2 parts by weight of LaserAT-8733, which were dried at 120°C for 4 hours, were made by White laser marking masterbatch is 12 parts by weight, carbon black M800 is 1 part by weight, 1010 parts by weight is 0.2, and 168 parts by weight is 0.4, mix well at room temperature, add long glass fiber EDR17-2400 -988A granulation, control glass fiber content at 20. The processing technology is: the speed of the main engine is 200rpm, the temperature of the first stage is 210°C, the temperature of the second stage is 220°C, the temperature of the third stage is 230°C, the temperature of the fourth stage is 240°C, the temperature of the fifth stage is 240°C, and the temperature of the sixth stage is 250°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com