A vacuum percolation flash tank and online regeneration method for heat transfer oil

A heat-conducting oil and flash tank technology, which is applied in the petroleum industry, hydrocarbon oil treatment, and multi-stage series-connected refining process treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

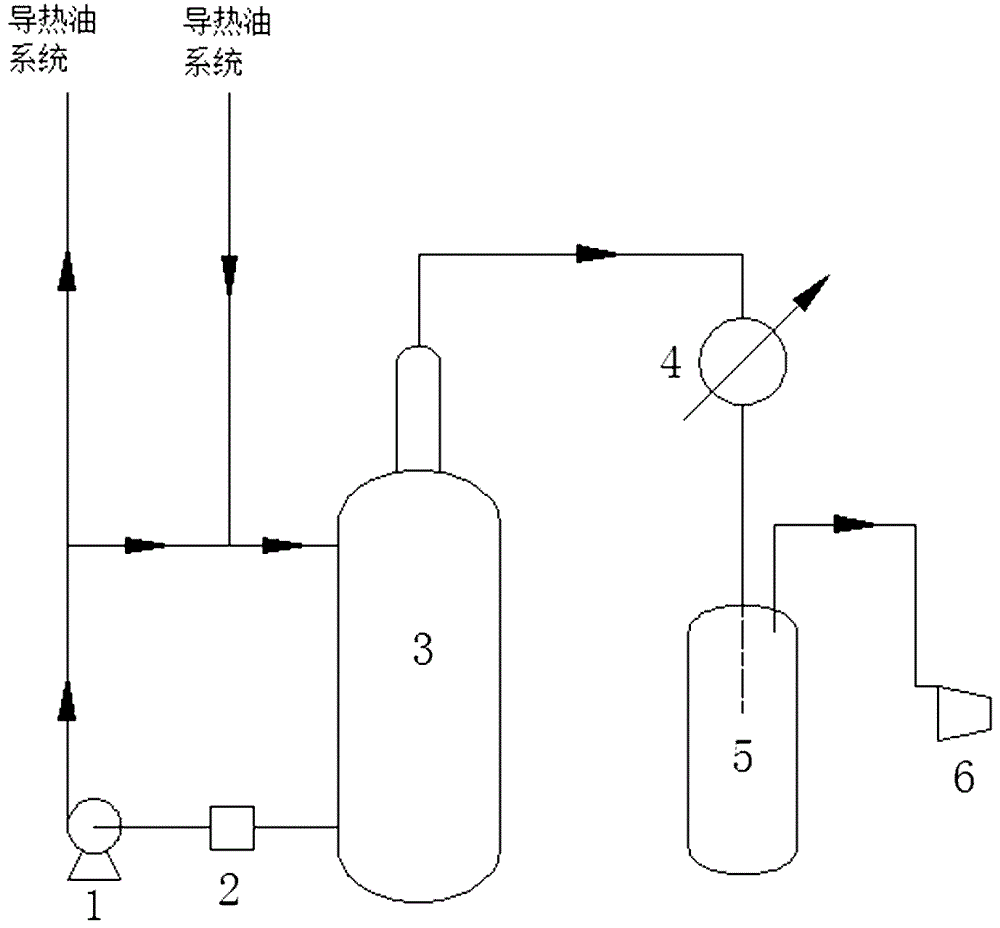

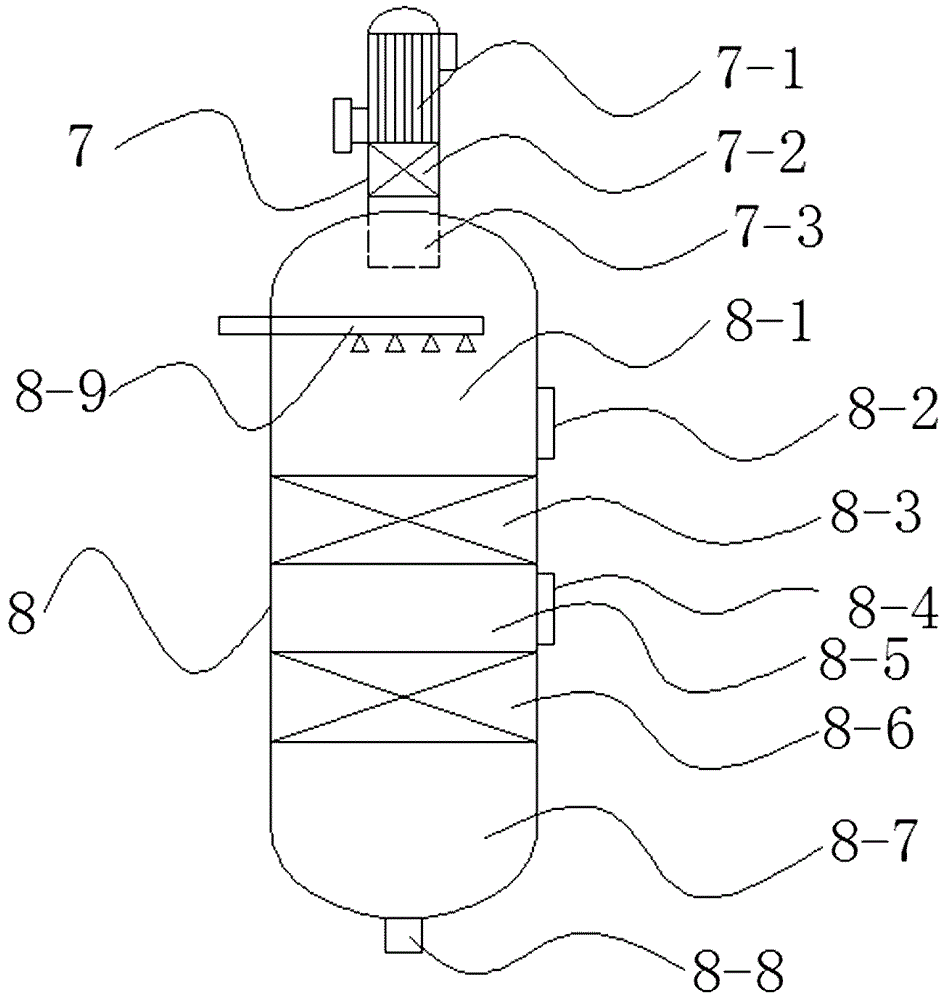

[0018] combined with figure 1 and attached figure 2 A method of on-line regeneration of the heat-conducting oil of the method of the present invention is as follows: the heat-conducting oil to be regenerated from the heat-conducting oil system flows into the decompression percolation flash tank 3 through the first pipeline, and passes through the Feed distributors 8-9 spray evenly. The heat transfer oil is flashed and gas-liquid separated in the gas-liquid separation chamber 8-1 to obtain a gas phase and a liquid phase. The liquid phase falls down into the oxide packing layer 8-3 for diafiltration. The material of the oxide packing layer 8-3 is a mixture of sodium hypochlorite and white clay, the mass ratio of sodium hypochlorite and white clay in the mixture is 1:20, and the mixture of sodium hypochlorite and white clay is Packed into bags with glass fiber cloth, the weight of each bag is 0.1 kg, the heavy components such as colloid and asphaltene in the liquid phase are a...

Embodiment 2

[0021] combined with figure 1 and attached figure 2 A method of on-line regeneration of the heat-conducting oil of the method of the present invention is as follows: the heat-conducting oil to be regenerated from the heat-conducting oil system flows into the decompression percolation flash tank 3 through the first pipeline, and passes through the Feed distributors 8-9 spray evenly. The heat transfer oil is flashed and gas-liquid separated in the gas-liquid separation chamber 8-1 to obtain a gas phase and a liquid phase. The liquid phase falls down into the oxide packing layer 8-3 for diafiltration. The material of the oxide packing layer 8-3 is a mixture of sodium hypochlorite and white clay, the mass ratio of sodium hypochlorite and white clay in the mixture is 1:10, and the mixture of sodium hypochlorite and white clay is Packed into bags with glass fiber cloth, the weight of each bag is 1.0 kg, the heavy components such as colloid and asphaltene in the liquid phase are a...

Embodiment 3

[0024] combined with figure 1 and attached figure 2, a heat transfer oil online regeneration method of the method of the present invention is as follows: the heat transfer oil to be regenerated from the heat transfer oil system flows into the decompression percolation flash tank 3 through the first pipeline, and passes through the gas-liquid separation chamber 8-1. Feed distributors 8-9 spray evenly. The heat transfer oil undergoes flash evaporation and gas-liquid separation in the gas-liquid separation chamber 8-1 to obtain a gas phase and a liquid phase. The liquid phase falls into the oxidation packing layer 8-3 for percolation, the material of the oxidation packing layer 8-3 is a mixture of sodium hypochlorite and clay, the mass ratio of sodium hypochlorite and clay in the mixture is 3:20, the mixture of sodium hypochlorite and clay Packed into bags with glass silk cloth, each bag has a mass of 2.0 kg, heavy components such as colloids and asphaltene in the liquid phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com