Method for preparing edible oil by cold pressing process

A technology of edible oil and cold pressing, which is applied in the direction of edible oil/fat, application, food science, etc., to achieve the effects of simple preparation process, increased industrial added value, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

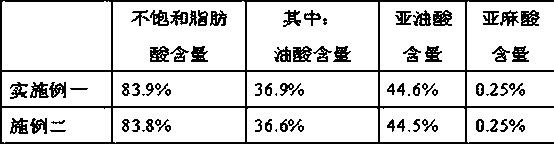

Examples

Embodiment 1

[0021] A) Stir-fry: Take fresh shelled Trichosanthes seeds, dry them in the sun, weigh 1000 kg, stir-fry at 55°C for 1 hour;

[0022] B) crushing: crushing the prepared material in step A); the mesh number of crushing is controlled at 20~100 mesh;

[0023] C) Heat preservation: Add 8kg of calcium bicarbonate evenly to the material. Then seal the material in the container and keep it warm for 2 hours at 55°C;

[0024] D) cake making: the material prepared by step C) is packaged as a round cake;

[0025] E) Cooking: place the material prepared in step D) in a steamer, and steam for 0.5 hours;

[0026] F) Squeeze: Squeeze the material prepared in step E) to obtain 152 kg of crude oil.

[0027] G) According to the weight ratio of the crude oil after pressing, add 0.23 kg of activated carbon, stir evenly, and filter with a diatomite filter tower to obtain 144.4 kg of refined oil.

[0028] The finished oil can be directly used for cooking food or mixed with other edible oils.

...

Embodiment 2

[0033] In the process of preparing Trichosanthes seed snack food, the raw material particles are required to be larger and have a higher particle consistency. The remaining products after classification are usually not plump enough, the particles are small, and the market added value is low. In this embodiment, the above raw materials Prepare cooking oil.

[0034] A) Stir-fry: Take fresh shelled Trichosanthes seeds, dry them in the sun, weigh 1000 kg of the remaining products after grading, and stir-fry for 1 hour at 52°C;

[0035] B) crushing: crushing the prepared material in step A); the mesh number of crushing is controlled at 20~100 mesh;

[0036] C) Heat preservation: Add 8.5kg of calcium bicarbonate evenly to the material. Then seal the material in the container and keep it warm for 2 hours at 55°C;

[0037] D) cake making: the material prepared by step C) is packaged as a round cake;

[0038] E) Cooking: place the material prepared in step D) in a steamer, and steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com