A kind of preparation method of biogas fermentation promoting bacterial agent

A biogas fermentation and bacterial agent technology is applied in the field of biogas fermentation-promoting bacterial agent preparation, which can solve the problems of severe separation and cultivation, affecting popularization and application, and difficulty in obtaining bacterial strains, and achieves reduction of labor costs and time costs, low cost, and low cost. The effect of easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

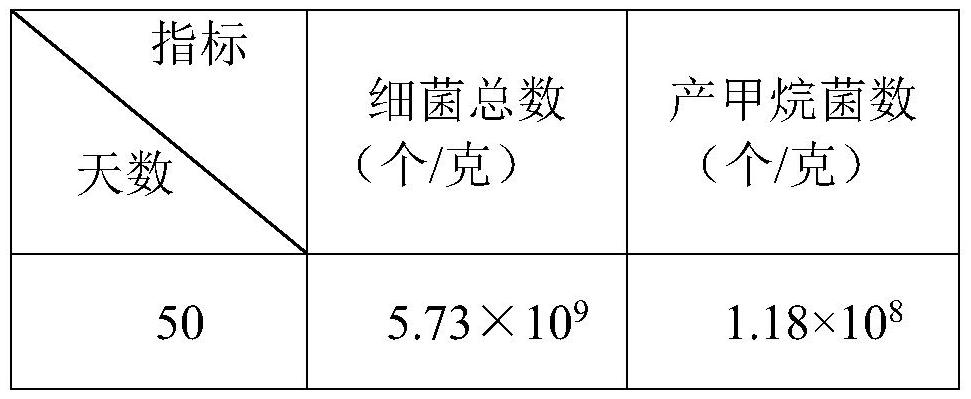

Embodiment 1

[0052] Fresh pig manure and rice straw powder with a weight ratio of 1:1 were used as fermentation substrates. The culture solution of each functional microorganism in the composite bacteria as inoculum is calculated by volume parts, respectively: the culture solution volume fraction of the rumen proteolytic bacteria is 8 parts, the culture fluid volume fraction of the syntrophomonas palmitic acid is 4 parts, the volume fraction of the culture solution of Thermobacterium faecalis is 8 parts, the volume fraction of the culture solution of Cellulophilus macroji is 10 parts, and the volume fraction of the culture solution of Proteobacterium glycolyticum is 10 parts, The volume fraction of the culture solution of Spirochete spirochete is 5 parts, the volume fraction of the culture fluid of Tunisia effluent toga is 5 parts, the volume fraction of the culture fluid of Enterobacter aerogenes is 5 parts, and the volume fraction of the culture fluid of Aminobacterium columbia is 5 part...

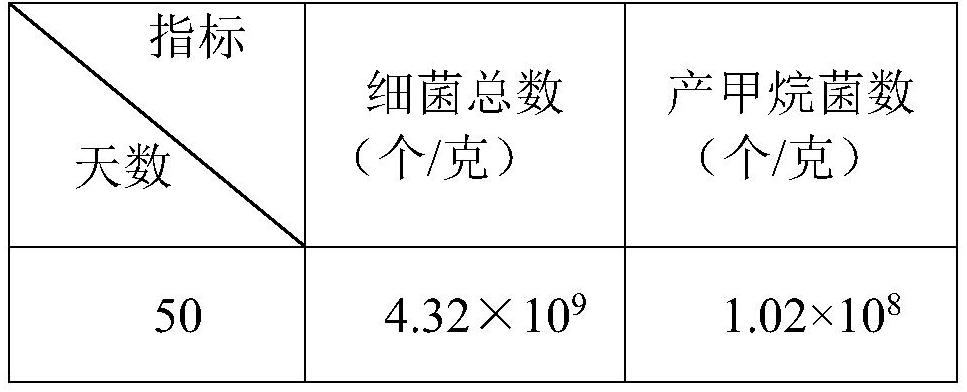

Embodiment 2

[0056] Fresh cow dung and rice straw powder with a mass ratio of 2:1 were used as fermentation substrates. The volume collocation ratios of each functional microorganism in the composite bacteria as the inoculum are respectively: the volume fraction of the culture solution of the rumen proteolytic bacteria is 5 parts, and the culture fluid volume fraction of the syntrophomonas palmitic acid is 5 parts. The volume fraction of the culture solution of Thermobacterium faecalis is 10 parts, the volume fraction of the culture solution of Cellulophilus gigantea is 12 parts, the volume fraction of the culture solution of Proteobacterium glycolyticum is 8 parts, and the cultivation of Spirochete spirochetes The volume fraction of the liquid is 5 parts, the volume fraction of the culture fluid of Tunisia effusions is 6 parts, the volume fraction of the culture fluid of Enterobacter aerogenes is 5 parts, and the volume fraction of the culture fluid of Aminobacterium Columbia is 5 parts, t...

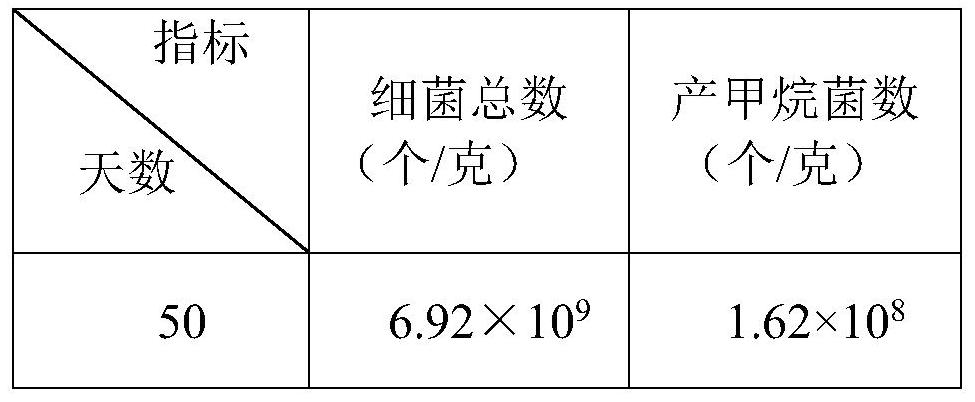

Embodiment 3

[0060] Fresh pig manure and corn stalk powder with a mass ratio of 1:1 were used as fermentation substrates. The volume collocation ratio of each functional microorganism in the composite bacteria as inoculum is respectively: the volume fraction of the culture solution of the rumen proteolytic bacteria is 8 parts, and the culture fluid volume fraction of the syntrophomonas palmitic acid is 4 parts, and the The volume fraction of the culture solution of Thermobacterium faecalis is 7 parts, the volume fraction of the culture solution of Cellulophilus gigantea is 9 parts, the volume fraction of the culture solution of Proteobacter glycolyticum is 10 parts, and the cultivation of Spirochete spirochetes The volume fraction of the liquid is 5 parts, the volume fraction of the culture fluid of Tunisia effusions is 5 parts, the volume fraction of the culture fluid of Enterobacter aerogenes is 5 parts, and the volume fraction of the culture fluid of Aminobacterium Columbia is 4 parts, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com