Air cylinder structure, compressor and air conditioner

A technology of cylinder and cylinder body, which is applied in the field of compressors, can solve the problems of increasing the friction between the cylinder and the roller, and the sliding plate is stuck, and achieve the effects of reducing the total weight of the cylinder, reducing friction, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

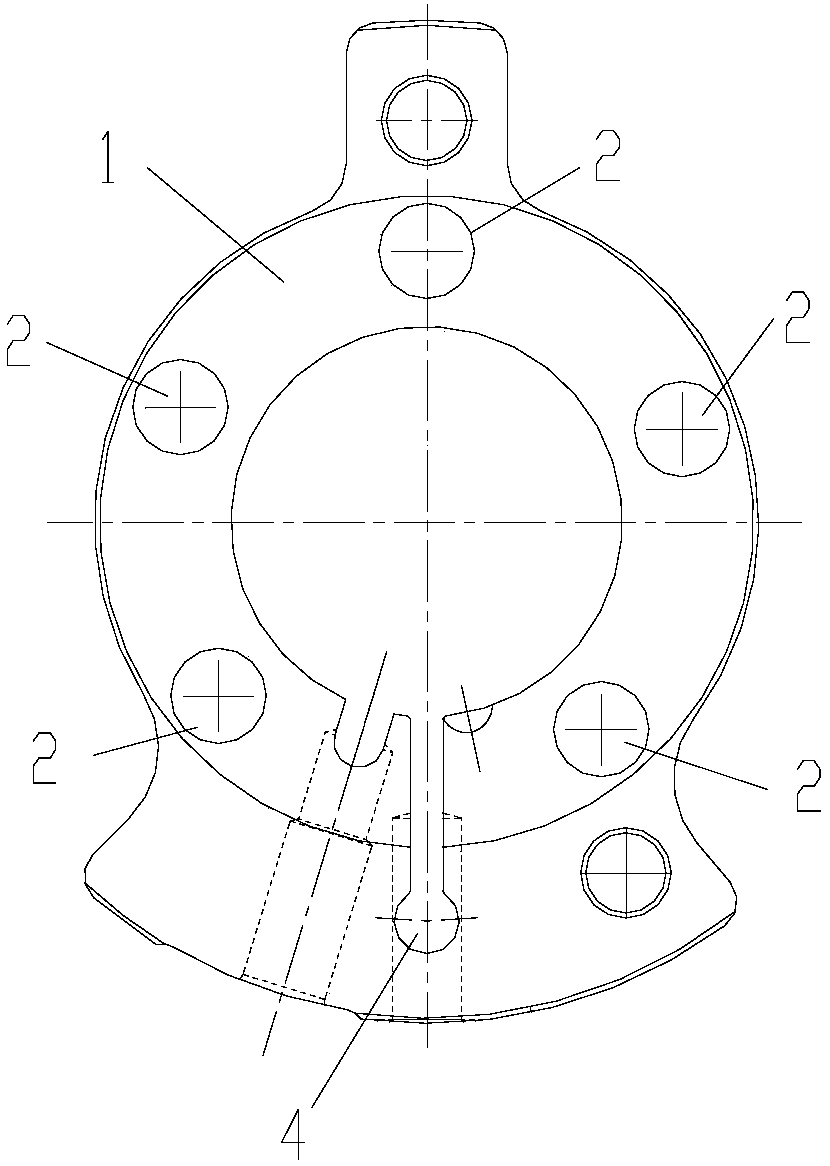

[0039] Such as Figure 1-3 Shown, the present invention provides a kind of cylinder structure, it comprises:

[0040] Cylinder body 1;

[0041] There is at least one mounting hole, which is arranged on the cylinder body 1 and is used to cooperate with threaded connectors (preferably screws) (to install the cylinder, upper flange, lower flange, etc.); and in the mounting hole At least one hole diameter is larger than the outer diameter of the threaded connector, forming an assembly hole 2;

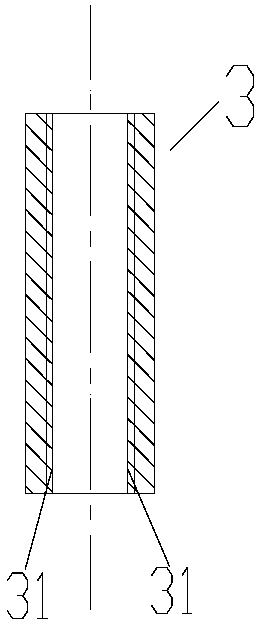

[0042] The sealing part 3 can be fitted into the fitting hole 2, and the threaded connector can be inserted into the inside of the sealing part 3 and mated with it.

[0043] By setting the sealing part, fitting it into the assembly hole, and making the diameter of the assembly hole larger than the threaded connector, and the threaded connector is inserted into the sealing part to connect with it, the threaded connector can be removed during the assembly process of the pump body assembly o...

Embodiment 2

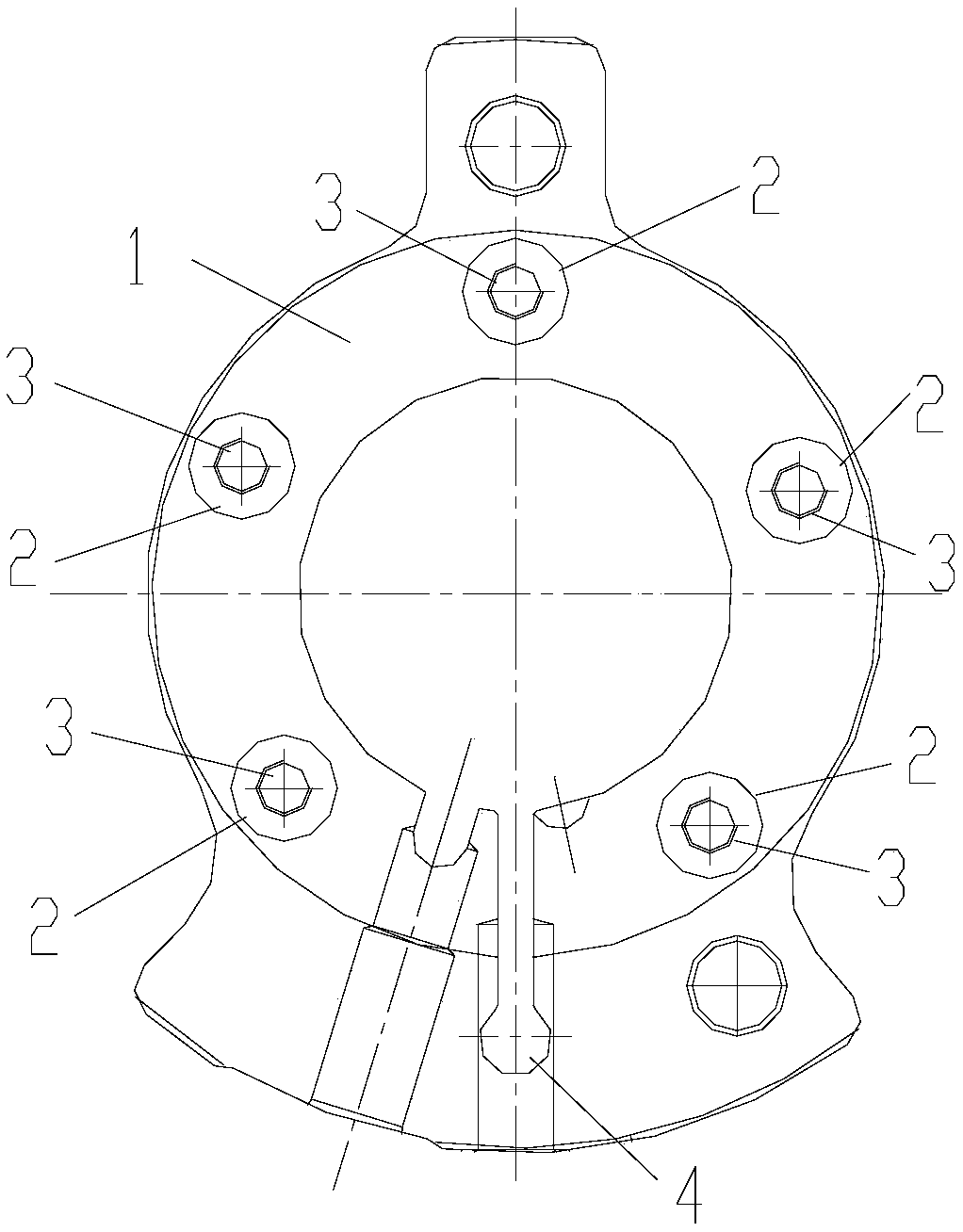

[0057] Such as Figure 4-6 As shown, this embodiment changes the number of mounting holes on the basis of Embodiment 1. The cylinder structure also includes a slide slot 4. In the installation hole, the Mounting holes are processed into the mounting holes 2 , and the rest of the mounting holes are processed into threaded holes 5 . In the cylinder structure of the present invention, the light holes are processed at the screw holes on both sides of the traditional cylinder near the slide groove, and then the seals processed with threaded holes are inserted into the light holes (the seals are iron hibiscus, which are equal to the cylinder, and the The threaded hole size on the cylinder is exactly the same as the original threaded hole size of the cylinder). Assembly is done by mating the screw in the threaded hole on the seal.

[0058] 1. During the assembly process of the pump body components of the compressor, the threaded part of the screw cooperates with the seal, which doe...

Embodiment approach 1

[0060] The first embodiment is that all the screw holes on the cylinder are improved, which can reduce the deformation of the inner wall of the cylinder and the inner wall of the slide groove at the same time. In the second embodiment, only the two screw holes on both sides of the slide groove are improved, so that the deformation of the inner wall of the slide groove is improved, but the deformation of the inner wall of the cylinder is not greatly improved. Generally, if the deformation of the inner wall of the cylinder is not large, no serious consequences will be caused, but the deformation of the slide groove can easily cause the slide to be stuck, or there will be a slide sound during operation, and the noise is abnormal.

[0061] Preferably,

[0062] The threaded connector can be inserted into the threaded hole 5 , and the external thread of the threaded connector is mated with the internal thread of the threaded hole 5 . In this way, the direct threaded connection betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com