Efficient sweeping robot

A sweeping robot and robot body technology, applied in the field of sweeping robots, can solve problems such as weak dust raising ability, difficulty in capturing dust at the suction port, and limitation of dust cleaning ability, so as to improve the dust cleaning effect and restrain outward diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

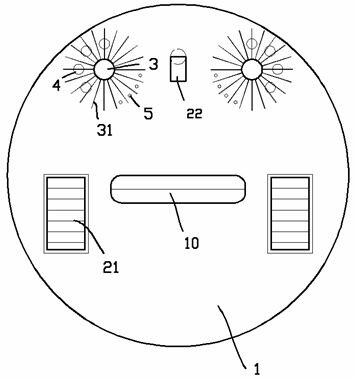

[0019] exist figure 1 In the first shown embodiment, the high-efficiency sweeping robot includes a robot body 1; the lower part of the robot body 1 is provided with a driving wheel 21 and a steering wheel 22; and the lower part of the robot body 1 is provided with a dust suction port 10; The front of the dust suction port 10 is provided with a dust brush 3 driven by a motor to continuously rotate; the bristles 31 of the dust brush 3 are made of conductive fibers; In the sweep area, there are permanent magnet posts 4 and metal needles 5; the permanent magnet posts 4 are set on the side of the sweep area away from the center of the dust suction port 10, and the metal pins 5 are set On the side of the sweeping area facing the center of the dust suction port 10 ; the metal needle 5 is grounded; and the bristles 31 of the dust brush 3 hit the metal needle 5 during the rotation process.

[0020] In the above-mentioned high-efficiency sweeping robot, the inner end of the bristles 31...

Embodiment 2

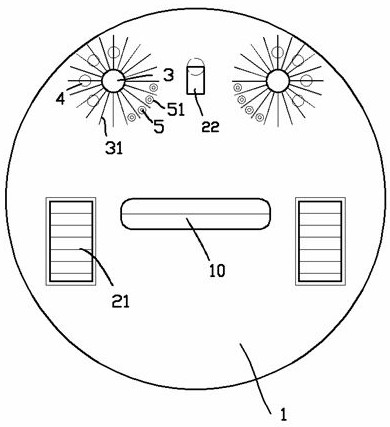

[0023] for figure 2 The second embodiment shown differs from the first embodiment in that: the metal needle 5 is rigidly connected to the bottom of the robot body 1, and its lower end forms a disc-shaped end cap 51, so that the middle section of the bristle 31 is covered with metal. After the needle 5 is blocked, the outer end of the bristle 31 is lifted upwards under the constraints of the metal needle 5 and the end cap 51, and passes over the end cap 51, so that the electrostatic charge at the end of the bristle 31 is absorbed by the metal needle 5 and the end cap. The cap 51 guides away, and also promotes the ejection effect of the outer end of the bristle 31, so that the dust is easy to fall off; and prevents the outer end of the bristle 31 that is inclined downward from reaching the metal needle 5, resulting in the outer end of the bristle. Static charges are difficult to conduct away.

Embodiment 3

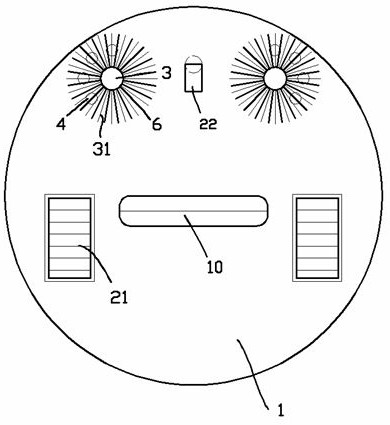

[0025] exist image 3 In the third embodiment shown, the high-efficiency sweeping robot includes a robot body 1; the lower part of the robot body 1 is provided with a driving wheel 21 and a steering wheel 22; and the lower part of the robot body 1 is provided with a dust suction port 10; The front of the dust suction port 10 is provided with a dust brush 3 driven by a motor to continuously rotate; the dust brush 3 includes circumferentially evenly distributed bristles 31, and a circumferentially evenly distributed metal wire 6 arranged above the bristle 31; The bottom of the robot body 1, in the sweeping area of the dust brush 3, is provided with a permanent magnet post 4; side.

[0026] In the above-mentioned high-efficiency sweeping robot, the permanent magnet column 4 is arranged inside the robot body 1 and does not protrude from the bottom of the robot body 1; the metal wire 6 is rigid.

[0027] When the high-efficiency sweeping robot in the third embodiment is working...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap