Grain drying device

A drying device and particle technology, applied in drying, dryer, heating device and other directions, can solve the problems of affecting the cleaning effect, small stirring range of the stirring shaft, etc., to improve the degree of cleanliness, good heating effect, and prevent the reproduction of microorganisms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

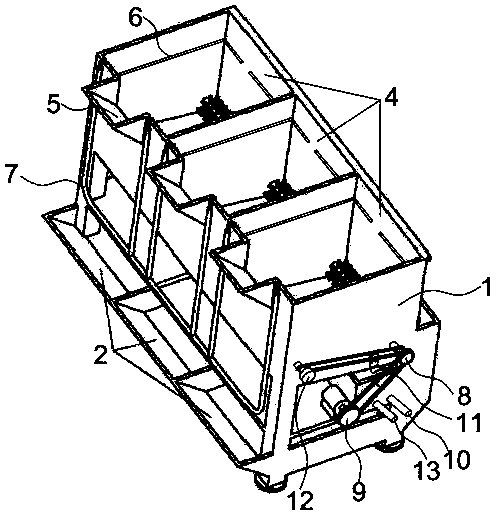

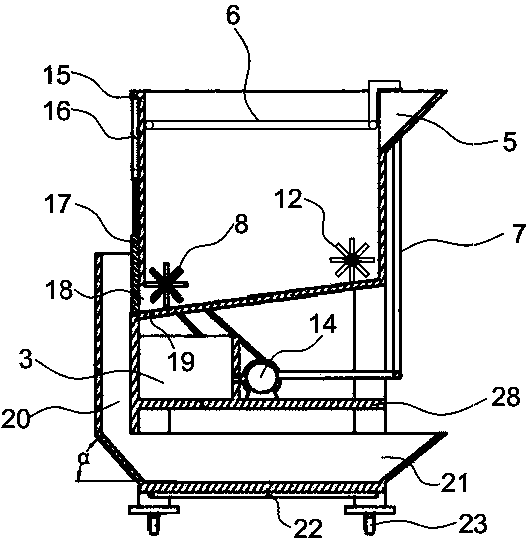

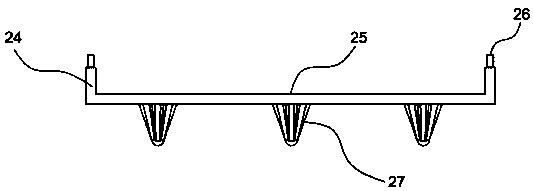

[0024] Such as Figure 1~6 As shown, a particle drying device includes a housing 1, the upper end of the housing 1 is provided with a cleaning chamber 4, the middle part of the housing 1 is provided with a support plate 28, and the upper end of the support plate 28 is provided with a water storage chamber 3, a filter mechanism 24 and Cleaning mechanism, the lower end of the housing 1 is provided with a collection bin 2, the bottom of the housing 1 is provided with a universal wheel 23, the right side wall of the housing 1 is provided with a stirring mechanism, the front side wall of the housing 1 is provided with a blocking mechanism, the cleaning chamber 4 and The bottom of the collection bin 2 is provided with a heating pipe 22. The device of the present invention has the functions of cleaning and drying, and all of them are integrated into one body, which improves the utilization rate of the device, and can clean and dry various materials at the same time, improving the work...

Embodiment 2

[0036] Such as Figure 1~6 As shown, a particle drying device, in actual operation, the cylinder 16 in the blocking mechanism is in the extended state, the discharge port 18 is blocked by the baffle plate 17, and the material containing impurities is poured into the cleaning chamber from the feed port 5 In 4, if there are many different materials, pour different materials into different cleaning chambers 4, turn on the water pump 14, and the water guide pipe 7 absorbs water from the water storage chamber 3, and flows into the cleaning chamber 4 through the water spray pipe 6. At the same time, turn on the motor 9 to make the stirring shaft I8 and the stirring shaft II12 work, and then drive the materials inside the cleaning chamber 4 to stir, so that the materials are cleaned more fully. The water in the cleaning chamber 4 passes through the bottom of the cleaning chamber 4. The outlet hole flows out into the water storage bin 3, and the impurities are collected in the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com