Low-defect-porous polishing pad

A polishing pad and polishing layer technology, which is applied in the direction of grinding machine tools, manufacturing tools, grinding tools, etc., can solve the problem of increasing the polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] This example is based on 1.5mm thick porous polyurethane polishing pad, which has 0.002m. 2 Opened vertical pores of an average pore area and a height of 0.39 mm. The polishing pad has a weight density of 0.409 g / ml. The polishing pad has an embossing groove of the size of Table 1.

[0047] Table 1

[0048] Size / slope

unit

Pad A

Pad 1

Pillow width

μM

1360×1360

1030×1030

Snap width at polished surface

μM

1200

1600

Groove depth

μM

400

580

Fluff layer (condensation) thickness

μM

530

530

Bottom pillar width

μM

2150

2100

Bottom groove width

μM

490

440

Groove taper

Spend

45

45

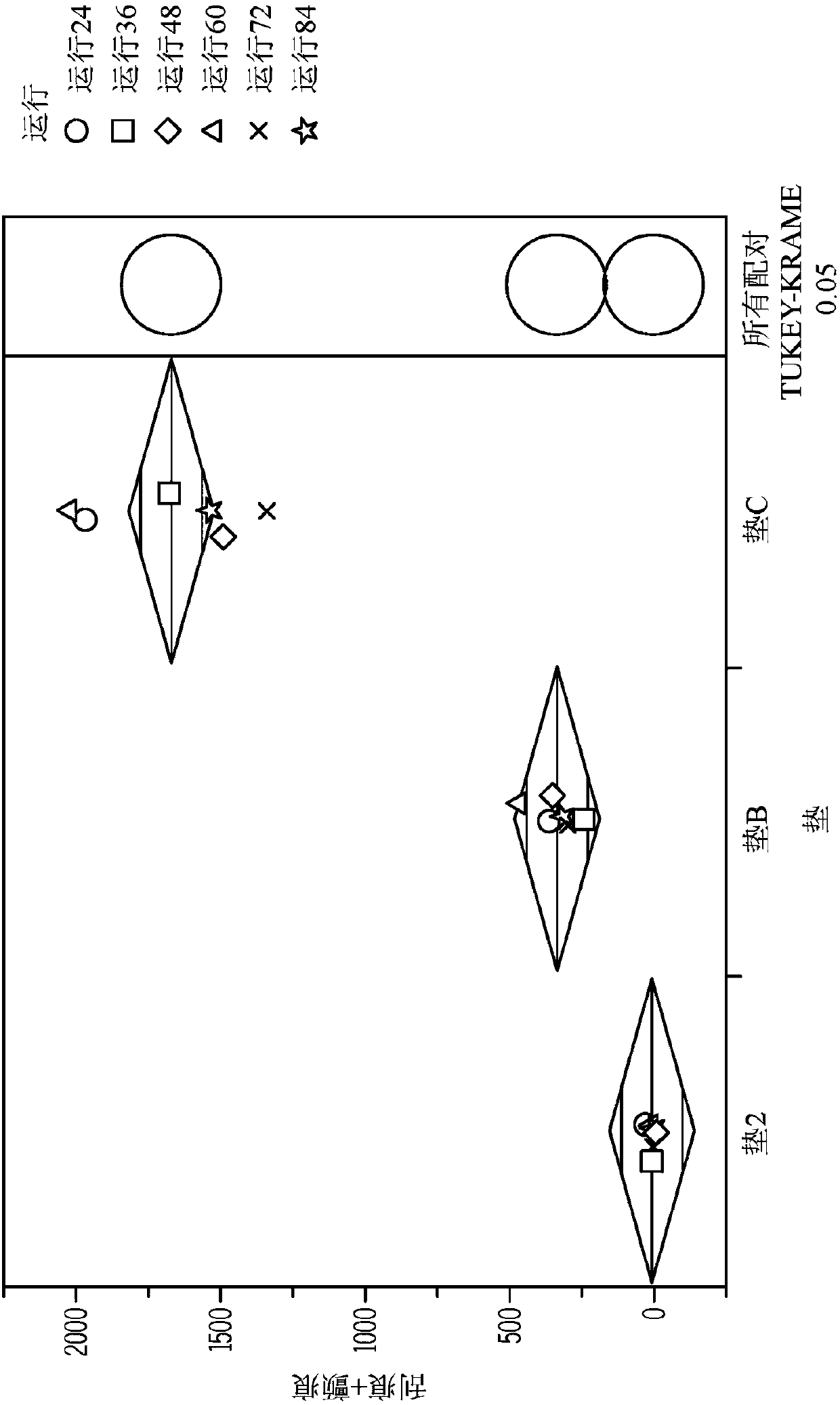

[0049] The table 1 embossed test pad was evaluated under an oxide CMP process configured for embossed depth styles. Each pad type is tested under the same process conditions. The removal rate, no uniformity% (NU%) and defects of the performance wafer are checked with the KLA-T...

example 2

[0116] The polyester felt roll has a thickness of 1.1 mM, and the weight of 334 g / m2 and the density of 0.303 g / m3. The felt is a blend of two polyester fibers that can be contracted (-55% at 70 ° C) than a ratio of contraction (-2.5% at 70 ° C). The first fiber has a weight of 2.10 Cg / 1000m, and the strength of 3.30 cn / dtex and 75% fracture elongation. The second fiber has a weight of 2.29 dtex (kg / 1000m), the strength of 2.91 c N / DTEX and 110% elongation at break. The upper surface of the felt is applied with Ag-E092 perfluorocarboxylic acid and its precursor. After the waterproof, the felt dried and burned to remove any fiber terminal protruding through the top layer of the felt.

[0117] A series of porous polishing pads are produced by the blend of thermoplastic plastics in the dimethylformamide solvent and embossed to the size of the pad 3-2 of Example 3. Table 6 provides a list of thermoplastic polyurethane components and their molar formulations. Samprene and C...

example 3

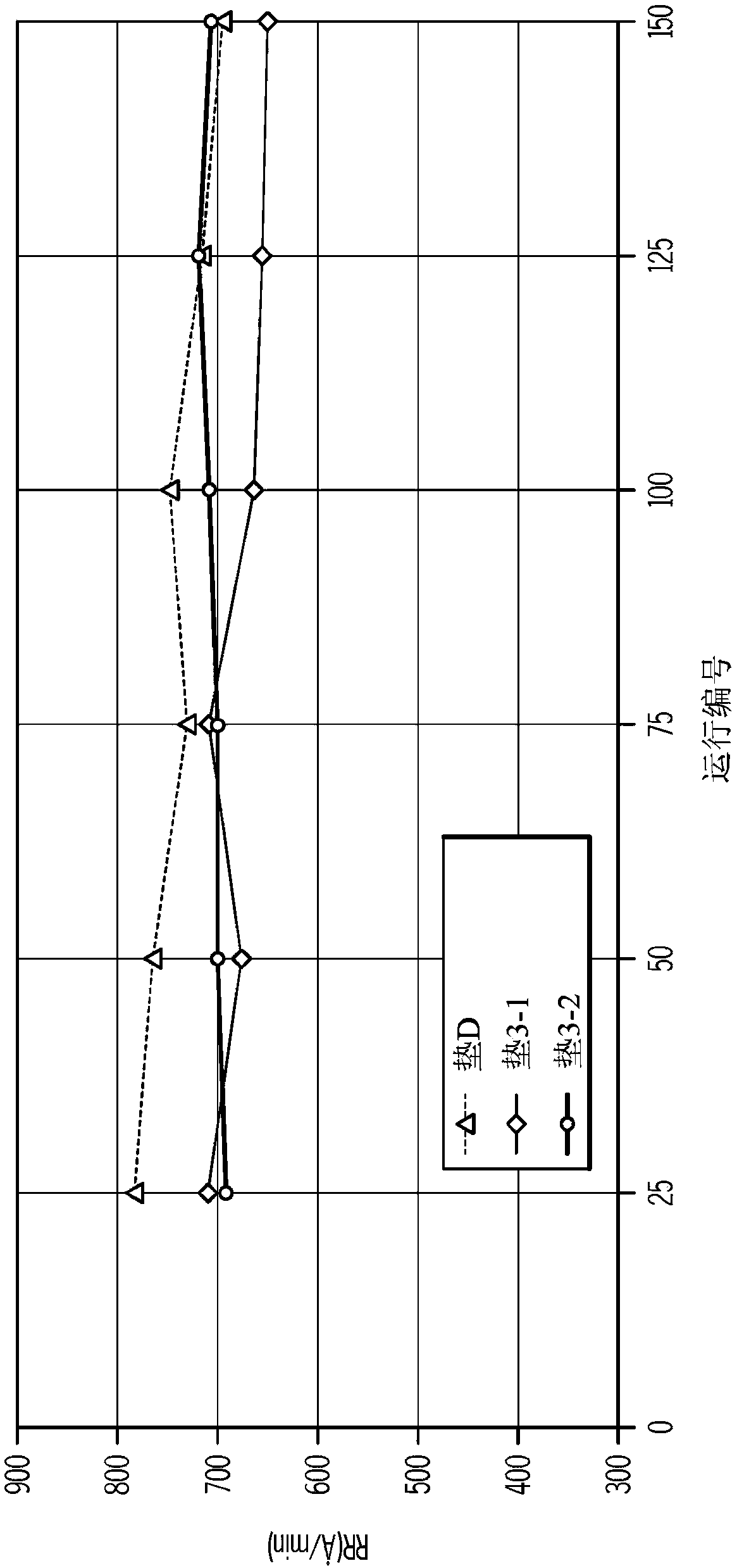

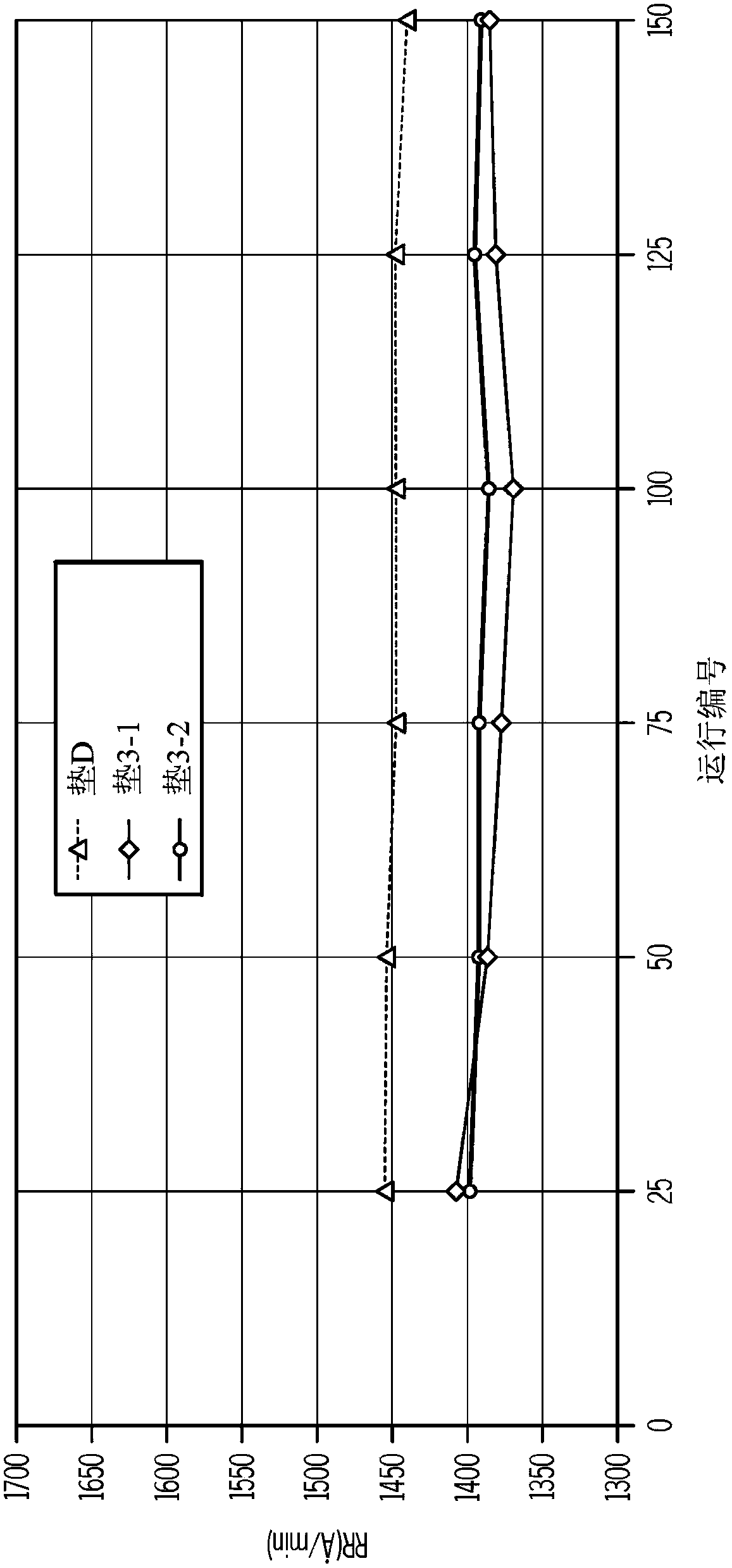

[0156] Two mats (pad 3; pad 3-1 and mat 3-2) of the commercial porous polishing pad "D" and Example 2 are embossed to different sizes. The pad 3-1 has an embossing design, wherein the width of the pillow is above the groove width at the polishing surface; and the pad 3-2 has an embossing design, wherein the groove width is more than the pillow width as measured at the polishing surface.

[0157] Table 12

[0158] Size / slope

unit

Pad D

Pad 3-1

Pad 3-2

Pillow width

μM

2750×2750

1480×1480

1135×1135

Snap width at polished surface

μM

1250

1026

1500

Groove depth

μM

450

342

480

Fluff layer (condensation) thickness

μM

720

489

489

Bottom pillar width

μM

2164

2095

Bottom groove width

μM

309

572

Groove taper

Spend

0

45

45

[0159] The mat was then polished under the conditions of Example 2. Table 13 and figure 2 As shown in the middle, pad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com