Robot workpiece locating control system and method

A technology of positioning control and robotics, which is applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve problems such as inaccurate workpiece processing, and achieve the effect of simple, easy to implement, and solve inaccurate workpiece processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

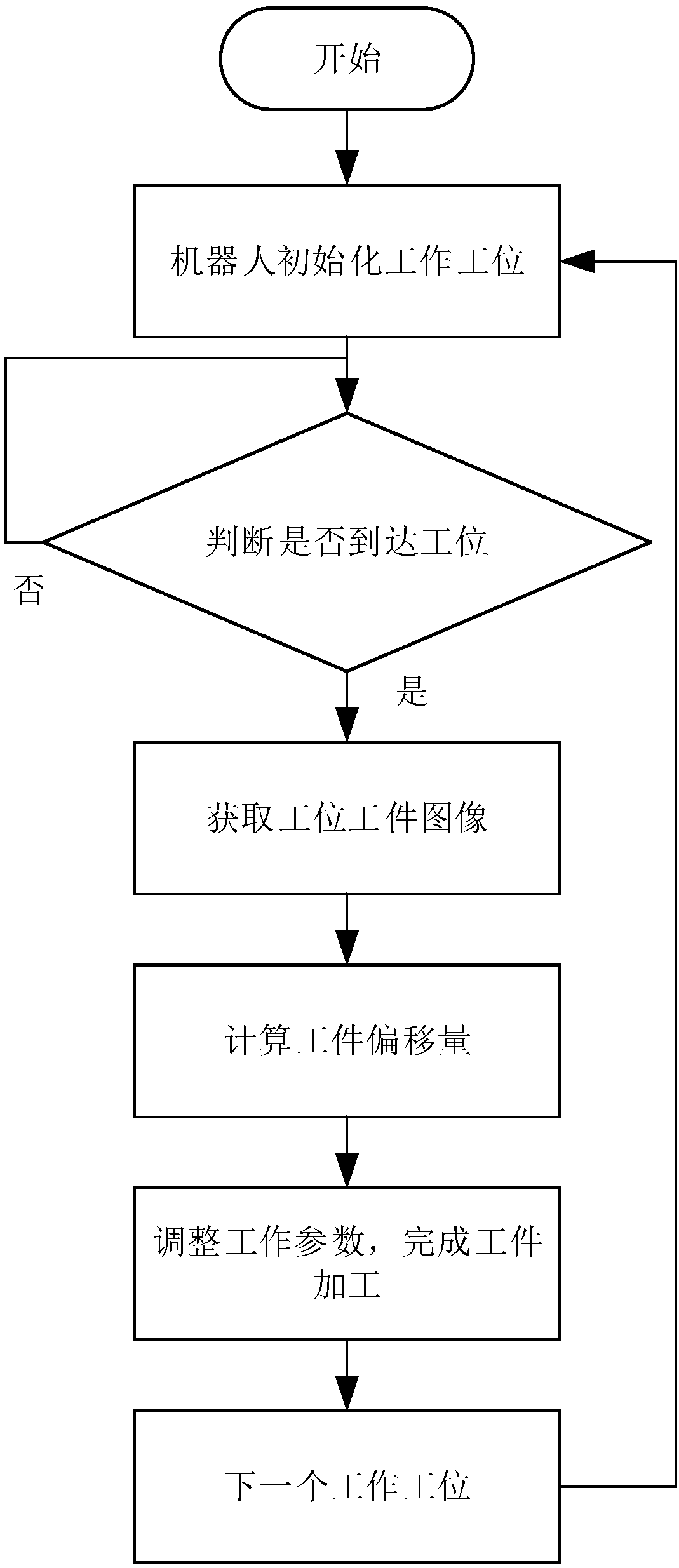

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

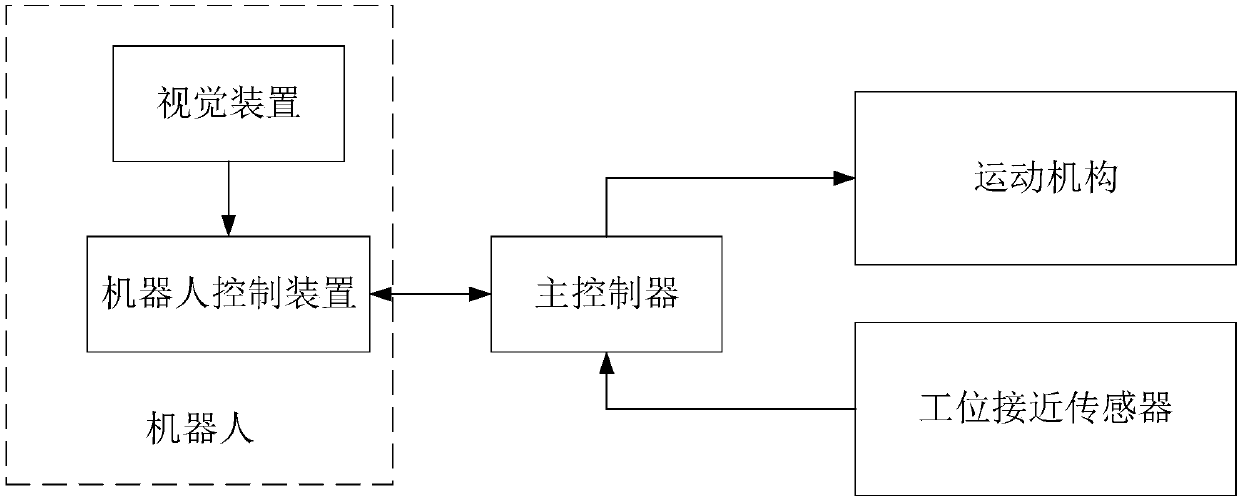

[0025] The invention provides a robotic workpiece positioning control system, such as figure 1 As shown, including robot, main controller, kinematic mechanism and station proximity sensor. Wherein the robot includes a robot control device and a vision device.

[0026] The main controller controls and connects the motion mechanism, the input signal of the main controller is connected with the station proximity sensor, the output signal of the main controller is connected with the robot control device; the signal of the robot control device is connected with the vision device.

[0027] The motion mechanism is used to drive the robot to switch stations, such as the transmission mechanism that provides the robot with linear motion. There are many types of such linear transmission mechanisms, such as synchronous belt type linear slide table or ball screw type lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com