Wine distillation equipment

A technology of distillation equipment and steam, applied in the field of wine distillation equipment, can solve the problems of affecting production efficiency, increasing production cost, waste, etc., and achieve the effect of accelerating industrial production efficiency, reducing production cost, and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

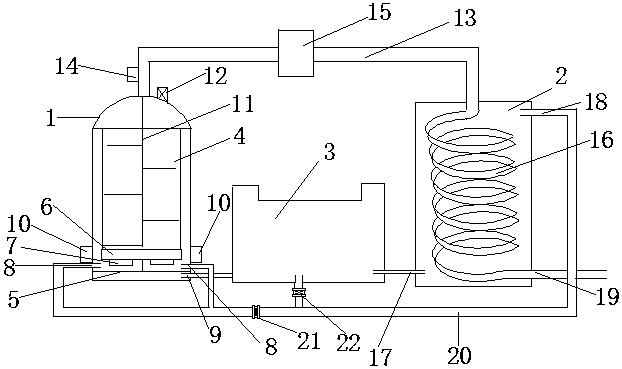

[0021] A wine distillation equipment, comprising a distillation cylinder 1, a condensation cylinder 2 and a cooling water tank 3, the distillation cylinder 1 is composed of an upper cylinder 4 and a lower cylinder 5, the upper cylinder 4 is placed on a cylinder base 6, the The lower cylinder 5 is divided into upper and lower layers, and the upper layer is evenly divided into left and right parts, each of which is provided with a heating motor 7, and the heating motor 7 is installed on the bottom of the cylinder seat 6, and two left and right Each heating space can significantly improve steam generation efficiency and save working time; there is a water inlet 8 on the left and right sides of the upper layer, and the water inlet 8 is used to deliver cold water for heating by the heating motor 7, and the lower layer There is a water outlet 9 on the right side of the lower layer of the cylinder 5, which is used to adjust the water level in the lower cylinder 5, and there is a water...

Embodiment 2

[0030] The difference between Embodiment 2 and Embodiment 1 is that the hot water outlets 18 are connected to the hot water pipes 20 respectively, and are connected with the water inlet 8 and the cooling water tank 3, and a regulating device is installed on the hot water pipes 20. Valve one 21 and control valve two 22, when the lower tube 5 needs water supply, open the control valve one 21, close the control valve two 22, the hot water flowing out of the hot water outlet 18 is preferentially supplied to the lower tube 5 Need, because what flows out is hot water, can meet the requirement without heating for a long time after entering described lower cylinder 5, has saved electric power greatly. When the lower cylinder 5 does not need water supply, close the control valve 1 21, open the control valve 2 22, the liquid flowing out of the hot water outlet 18 enters the cooling water tank 3, and continues to supply the cooling work of the condensing cylinder after cooling .

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com