Double-layer wick imperforated high-efficiency cooling turbine guide vane device

A technology for cooling turbine and guide vane devices, which can be applied to stators, engine components, machines/engines, etc., and can solve problems such as complex flow and flow field structures in cascade flow channels, uneven temperature of turbine blades, and increased cooling gas consumption. , to achieve the effect of increasing the carrying limit, increasing the capillary limit, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

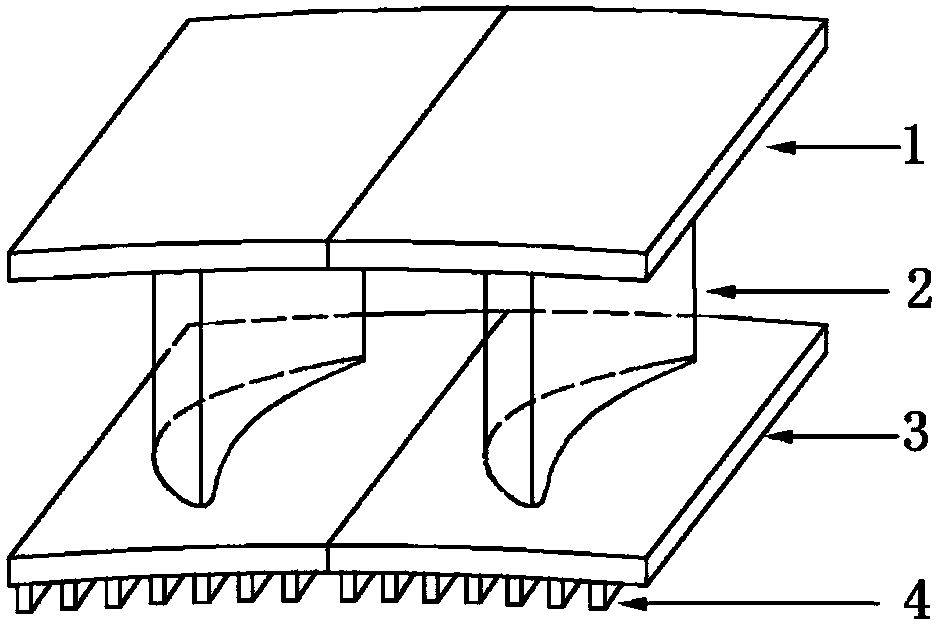

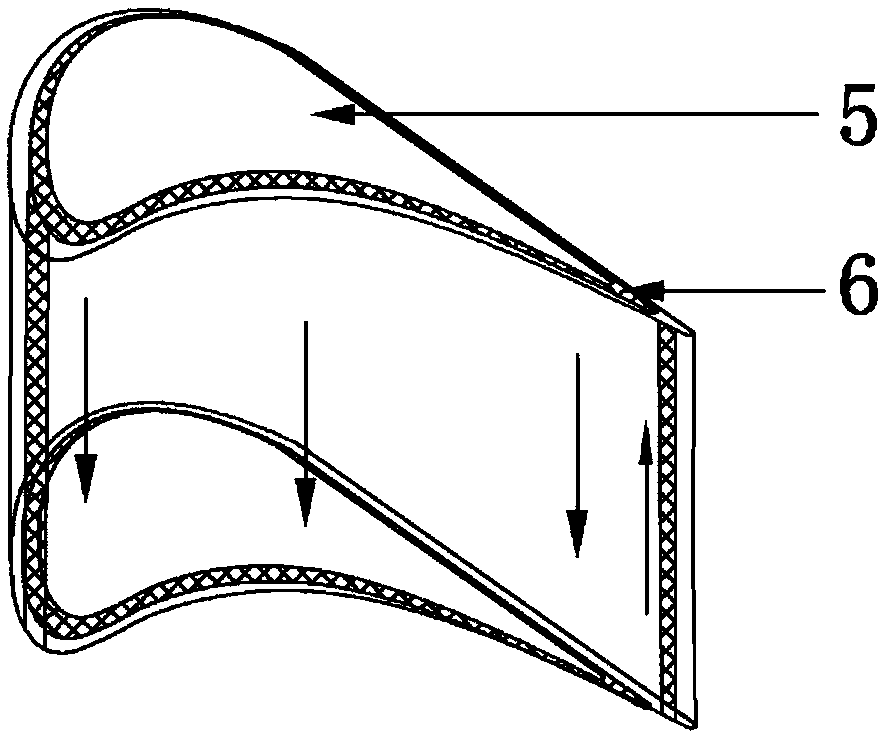

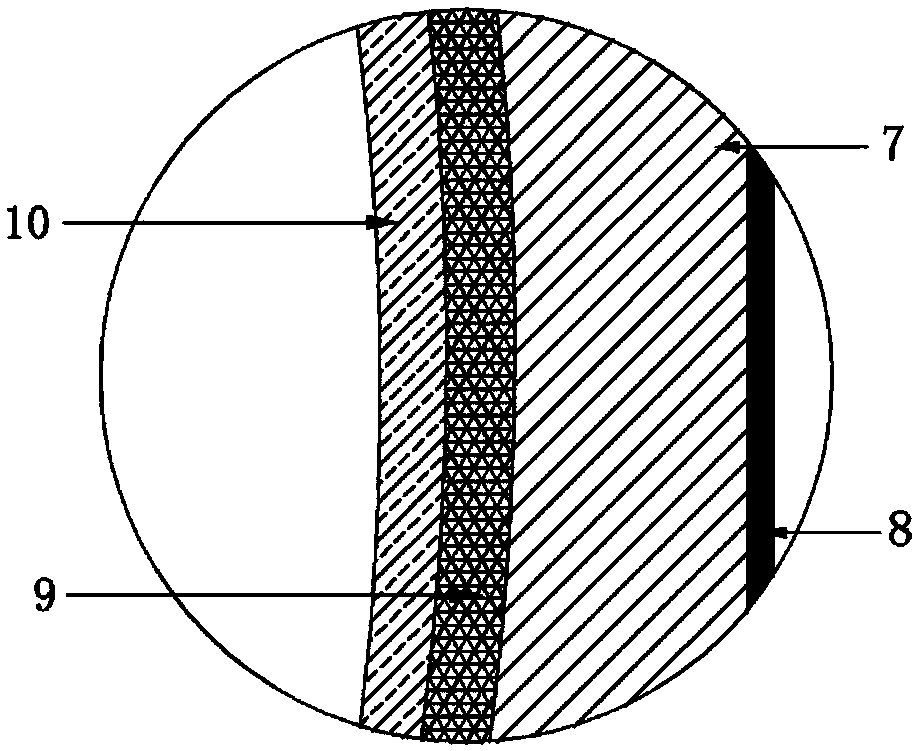

[0021] The utility model relates to a double-layer liquid-absorbing core without openings and a high-efficiency cooling turbine guide vane device, which comprises a turbine guide vane device and a double-layer liquid-absorbing core hot plate. The turbine guide vane device includes a diaphragm outer ring 1, a turbine blade 2, a vane holding ring 3, and fins 4, wherein the turbine blade 2 is an evaporation section, and the vane holding ring 3 is a condensation section. The diaphragm outer ring 1 is fixed on the upper surface of the turbine blade 2 . The ribs 4 are rectangular parallelepiped groove structures. The vane holding ring 3 is a hollow structure, the upper surface of the vane holding ring 3 has an opening, the outer edge of the opening is fixed to the lower surface of the turbine blade 2, the vane holding ring 3 communicates with the interior of the turbine blade 2 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com