Slant product width detecting device and detecting method based on same

A width detection and product technology, applied in the field of measurement, can solve the problem of not satisfying the Gaussian imaging formula, etc., and achieve the effect of easy batch detection and control, fast detection speed and sensitive response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

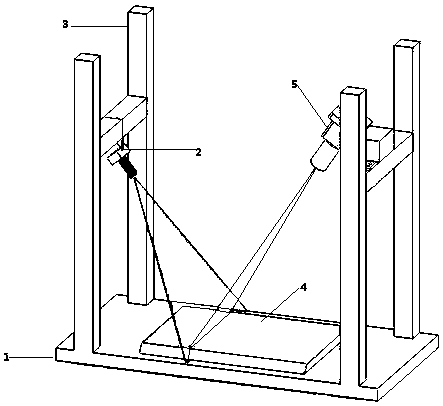

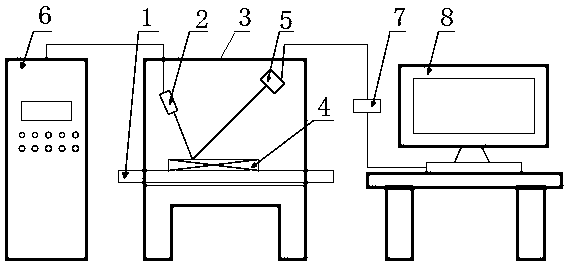

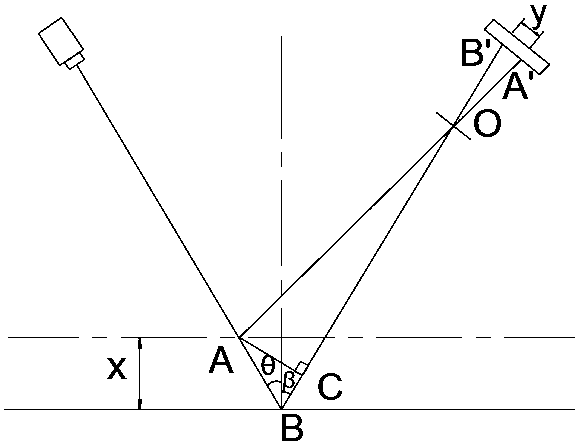

[0026] figure 1 It is a structural schematic diagram of an oblique beam product width detection device according to the present invention; figure 2 It is a system structure diagram of the oblique-beam type product width detection device described in the present invention.

[0027] Such as figure 1 and figure 2 Shown: Oblique-type product width detection device, including conveyor 1, laser emitter 2, bracket 3, area array industrial camera 5, bracket 3 bridge-type erected on conveyor 1, along the conveying direction of conveyor 1, in turn on A laser emitter 2 and an area array industrial camera 5 are arranged on the bracket 3, and the light source emitted by the laser emitter 2 to the surface of the product 4 under test on the transfer table 1 is received by the area array industrial camera 5 after being reflected by the product 4 under test , while the area array industrial camera 5 communicates with a computer 8 at the same time, a data acquisition card 7 is also arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com