Production method of free nanometer columnar array for improving luminescence of OLED device

A manufacturing method and columnar technology, which is applied in the field of OLED device luminescence and micro-nano structure manufacturing, can solve the problems of high cost, high manufacturing process requirements, and complicated manufacturing process, and achieve the effects of low cost, simple process, and improved luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a detailed description of the embodiments of the present invention. Based on the technical solution of the present invention, the present embodiment provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

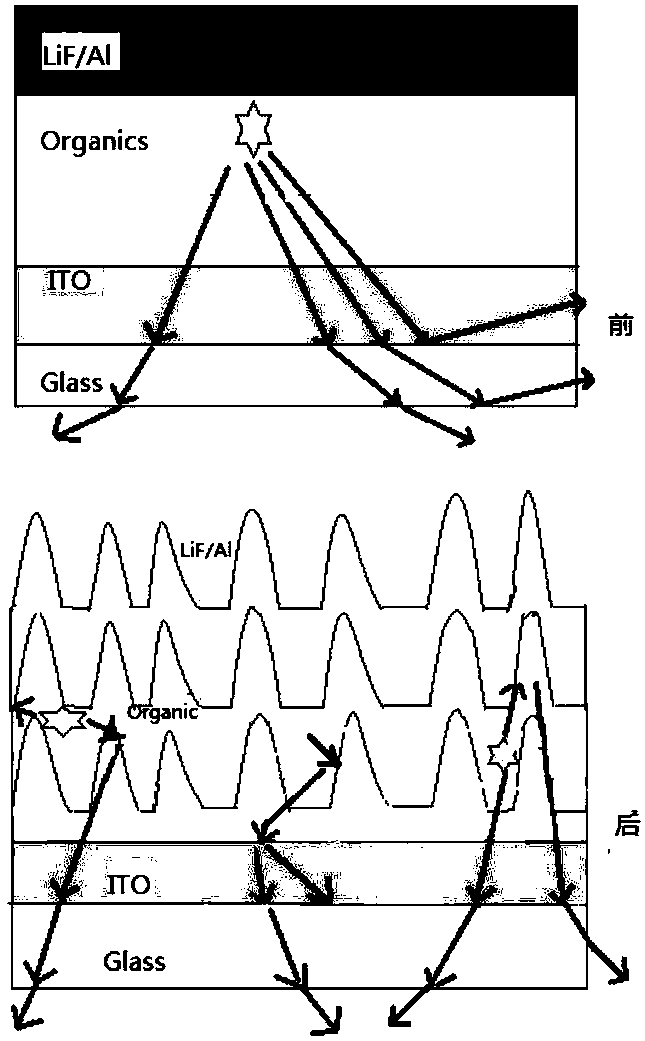

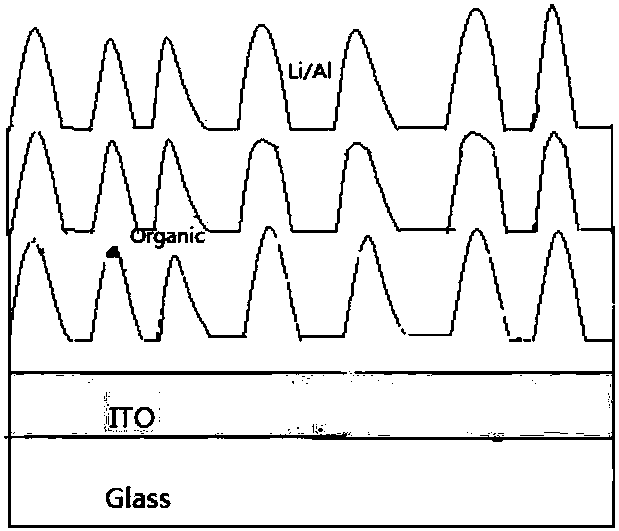

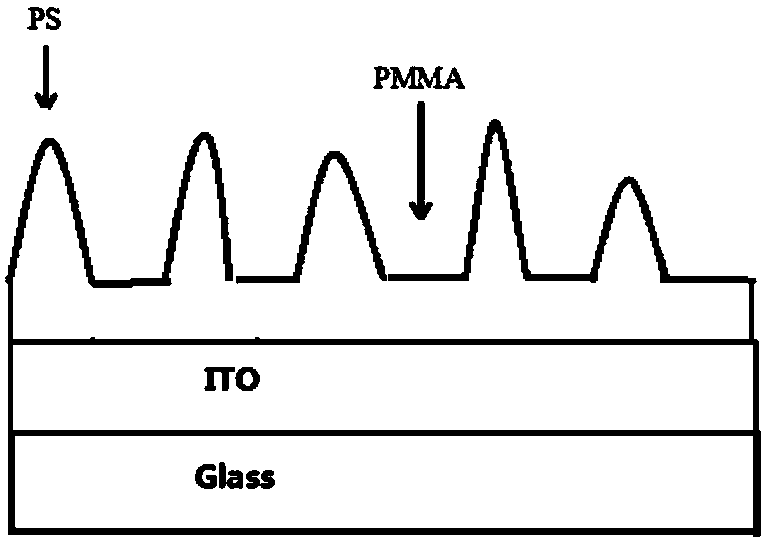

[0034] Such as figure 1 , 2 , 3, and 4, a method for making a free nanocolumn array for increasing the effective light-emitting area, comprising the following steps:

[0035] 1) ITO substrate cleaning: first rinse the ITO substrate with deionized water, then place the substrate in the laboratory ITO conductive glass cleaner with a volume concentration of 5% and deionized water for ultrasonic cleaning, and blow the cleaned substrate with nitrogen Dry, then dry on a hot table at 100°C for 10 minutes to remove residual water stains;

[0036] 2) UV ozone treatment: Place the ITO substrate cleaned in step 1) in a UV cleaning machine to remove organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com