Pretreatment device and soil in-situ remediation system

A pretreatment device and in-situ remediation technology, applied in the field of soil remediation, can solve the problems of unsatisfactory and unsatisfactory remediation effects of soil secondary pollution, and achieve the effect of improving secondary pollution, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

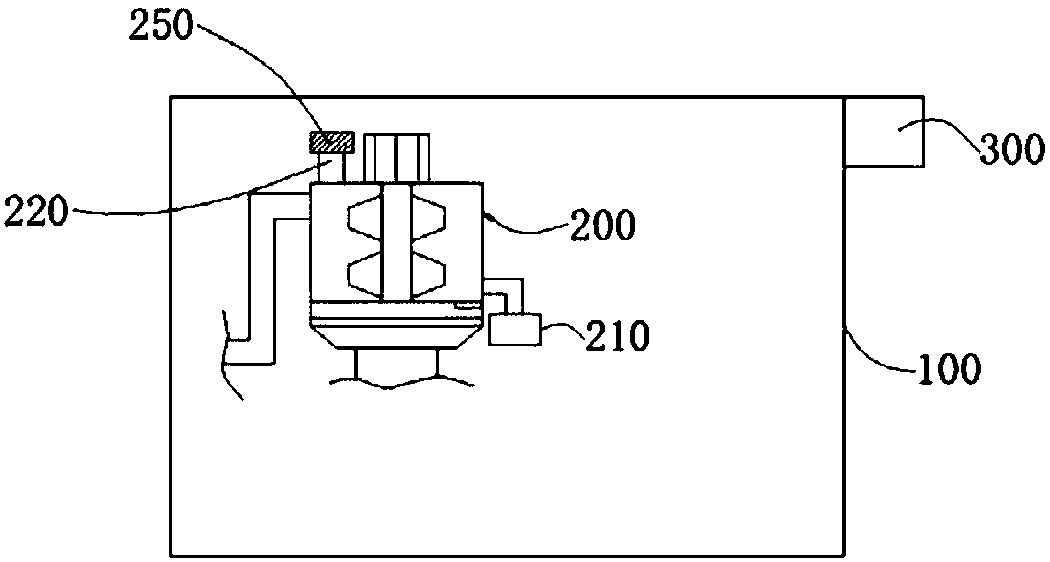

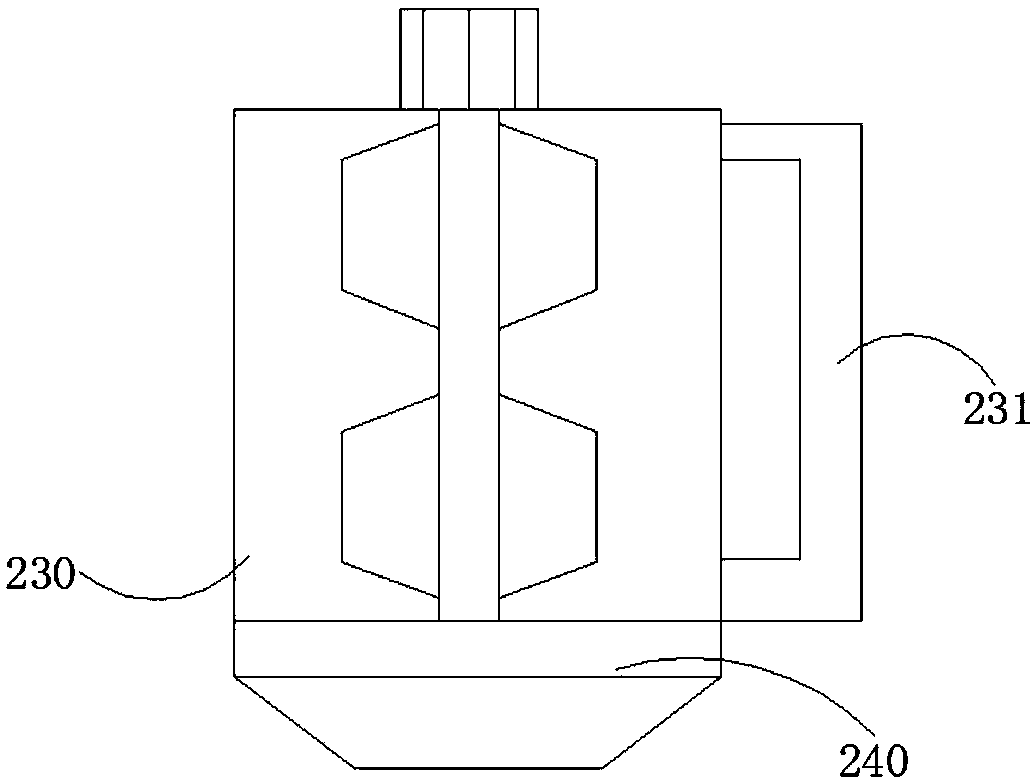

[0037] Such as Figure 1 to Figure 4 As shown, this embodiment provides a pretreatment device, including a closed chamber 100, a crushing and screening device 200 disposed in the closed chamber 100, and an exhaust gas treatment device 300 communicated with the closed chamber 100; wherein, the crushing and screening device 200 is used for crushing and screening the soil to be repaired. The crushing and screening device 200 is fixed with a first blower 210, and the first blower 210 blows air to the soil to be repaired in the crushing and screening device 200, and blows the air in it. Exhausted from the first exhaust port 220 into the closed chamber 100 ; the exhaust gas treatment device 300 is used to treat the gas in the closed chamber 100 and discharge the gas to the outside of the closed chamber 100 .

[0038]In this pretreatment device, the crushing and screening device 200 is used for crushing and screening the soil to be repaired in it, so that the particle size of the soi...

Embodiment 2

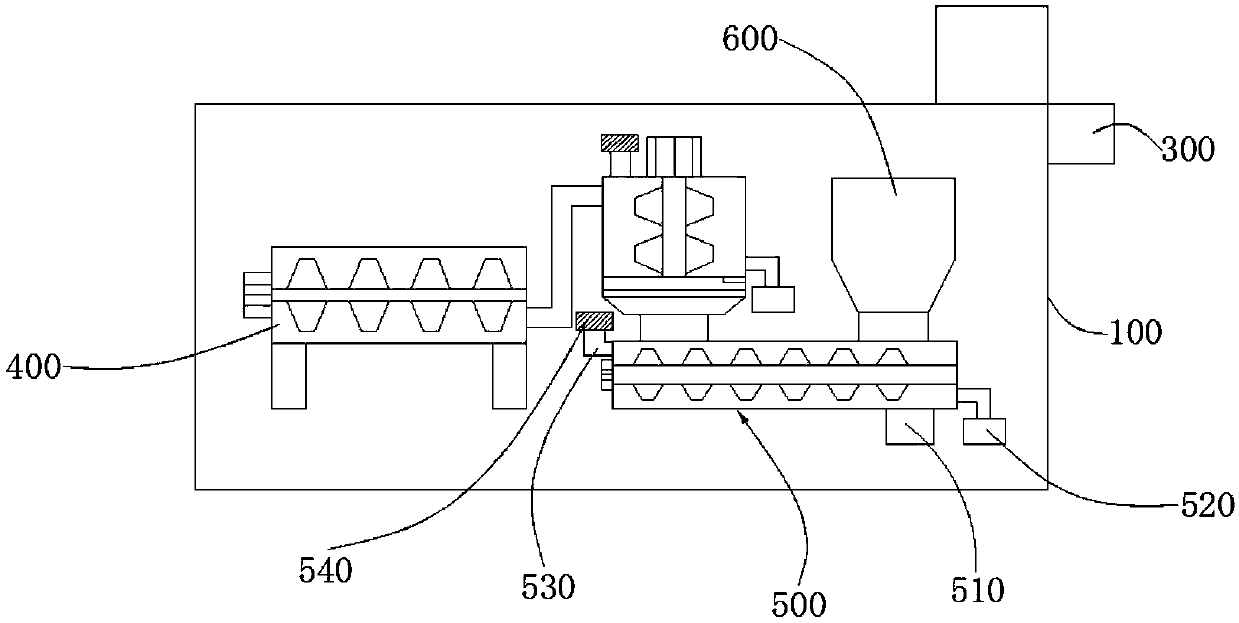

[0046] Such as image 3 and Figure 4 As shown, the present embodiment 2 provides a soil in-situ remediation system, including the pretreatment device in the above-mentioned embodiment 1, and also includes the conveying device 400, the stirring device 500 and the stirring device 500 arranged in the closed chamber 100 Provide a medicament storage device 600 for repairing soil agents; the delivery device 400 is used to transport the soil to be repaired to the crushing and screening device 200 for crushing and sieving, and the crushed and sieved soil is transported to the stirring device 500, and from Outlet 510 discharges.

[0047] By setting the above-mentioned pretreatment device in the soil in-situ remediation system, wherein, the parts involved in the pretreatment device in the second embodiment are the parts with the same name as the parts involved in the pretreatment device in the first embodiment, in terms of structure, Transformation forms, connection relationships, wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com