Preparation method of inorganic porous ceramic membrane

An inorganic porous and ceramic membrane technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of low oil removal rate of ceramic membranes, and achieve high renewable utilization rate, good reproducibility, acid and alkali resistance Good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0035] A preparation method of an inorganic porous ceramic membrane, comprising the following steps:

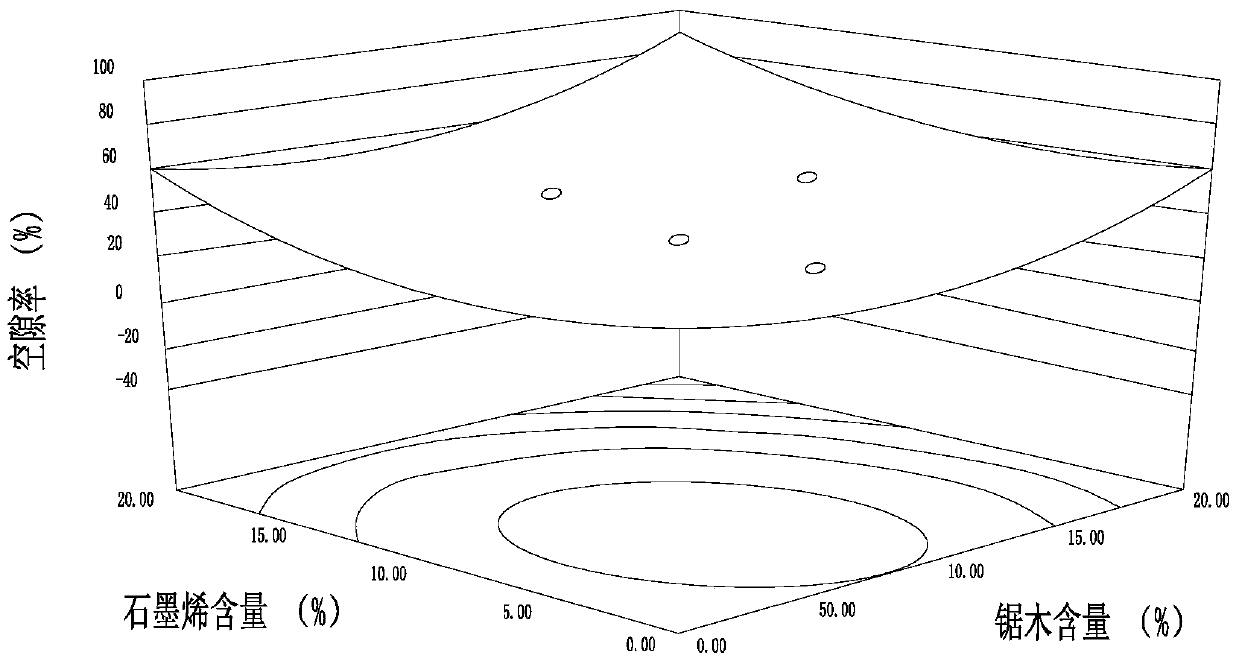

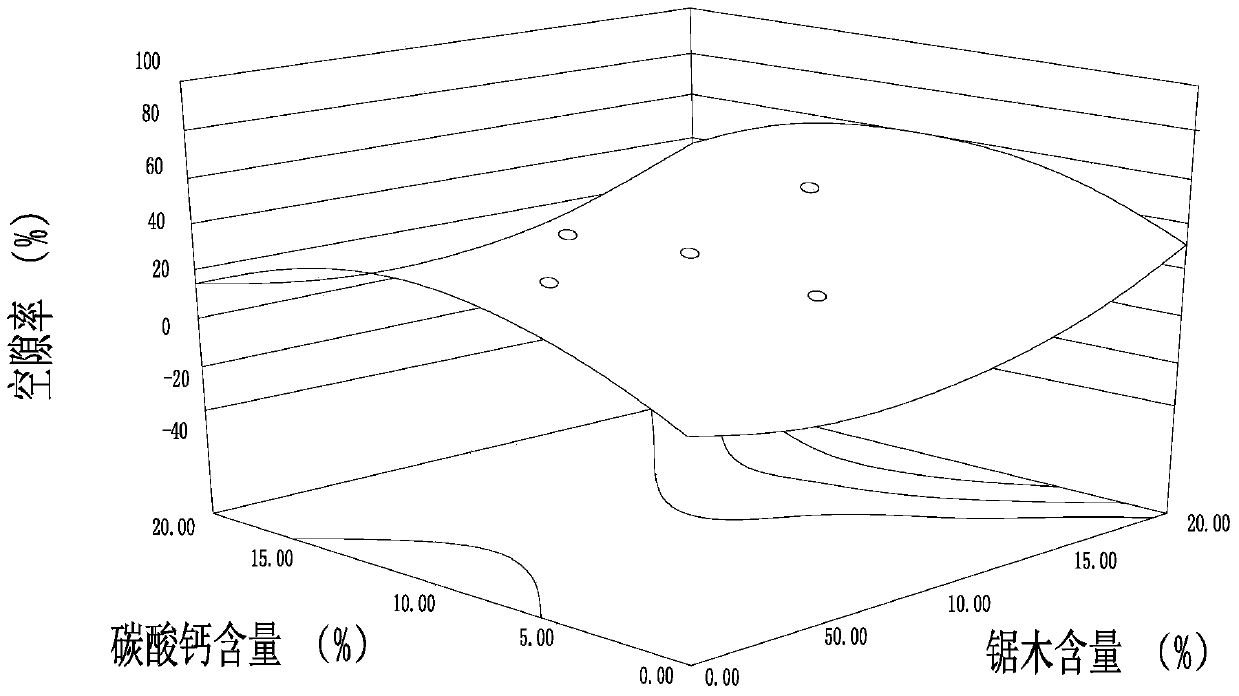

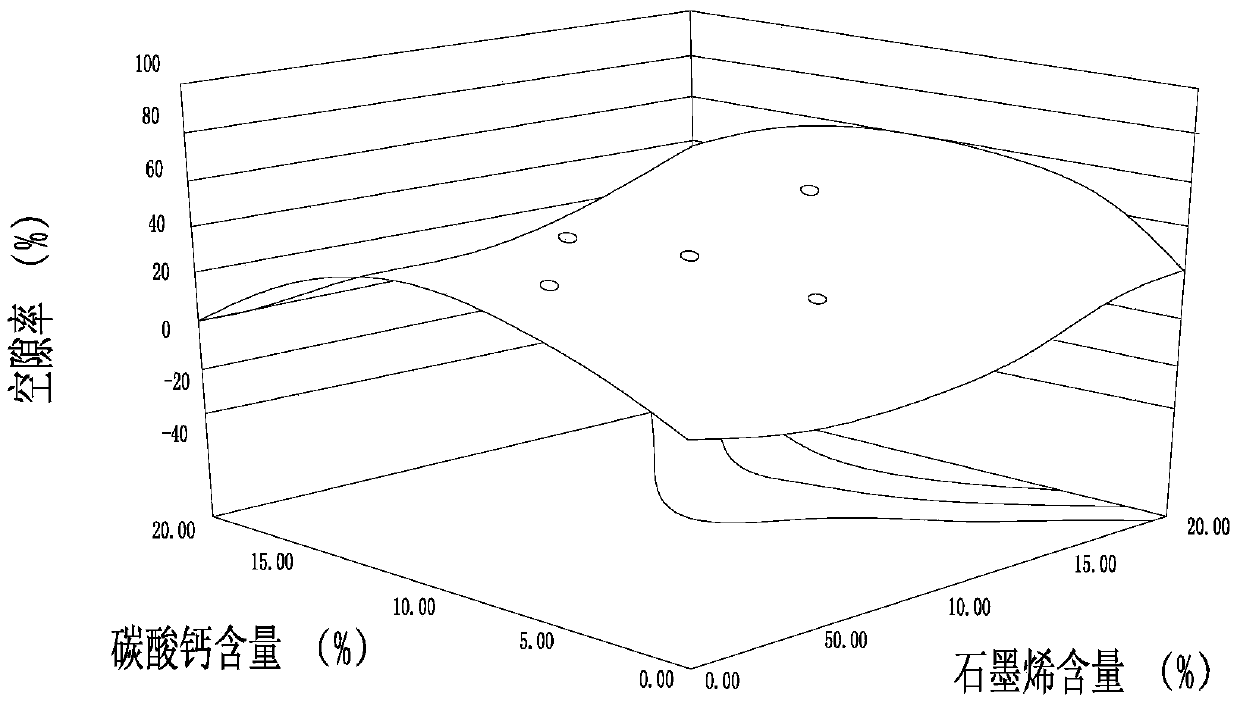

[0036] ① Weighing: Weigh the raw materials, pore-forming agent, and sintering aid according to a certain ratio, and mix them; the raw material is diatomite, and the pore-forming agent includes sawdust, graphene and CaCO 3 , the sintering aid is TiO 2 ;

[0037] ② Wet milling: select a ball mill, put the weighed materials, agate beads and distilled water into the ball mill together, the ratio of materials, agate beads and distilled water is 2:1:1, the materials include raw materials, pore-forming agents, sintering aids The agent is fully rotated by the ball mill to make the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com