Laser adjusting device and method for adjusting stress generated during laser additive manufacturing or remanufacturing

A laser additive and control device technology, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of difficulty in ensuring the global optimal parameters of process parameters, and difficulty in realizing optimization methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

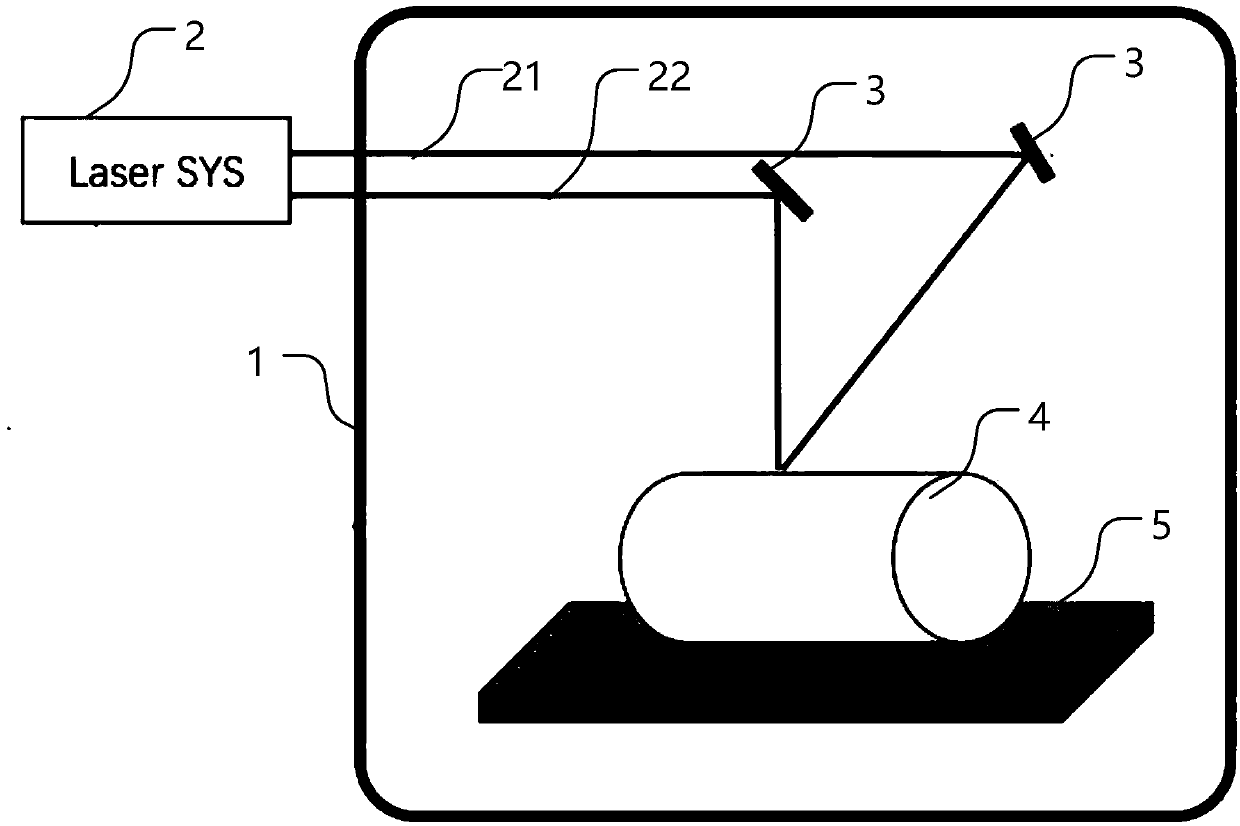

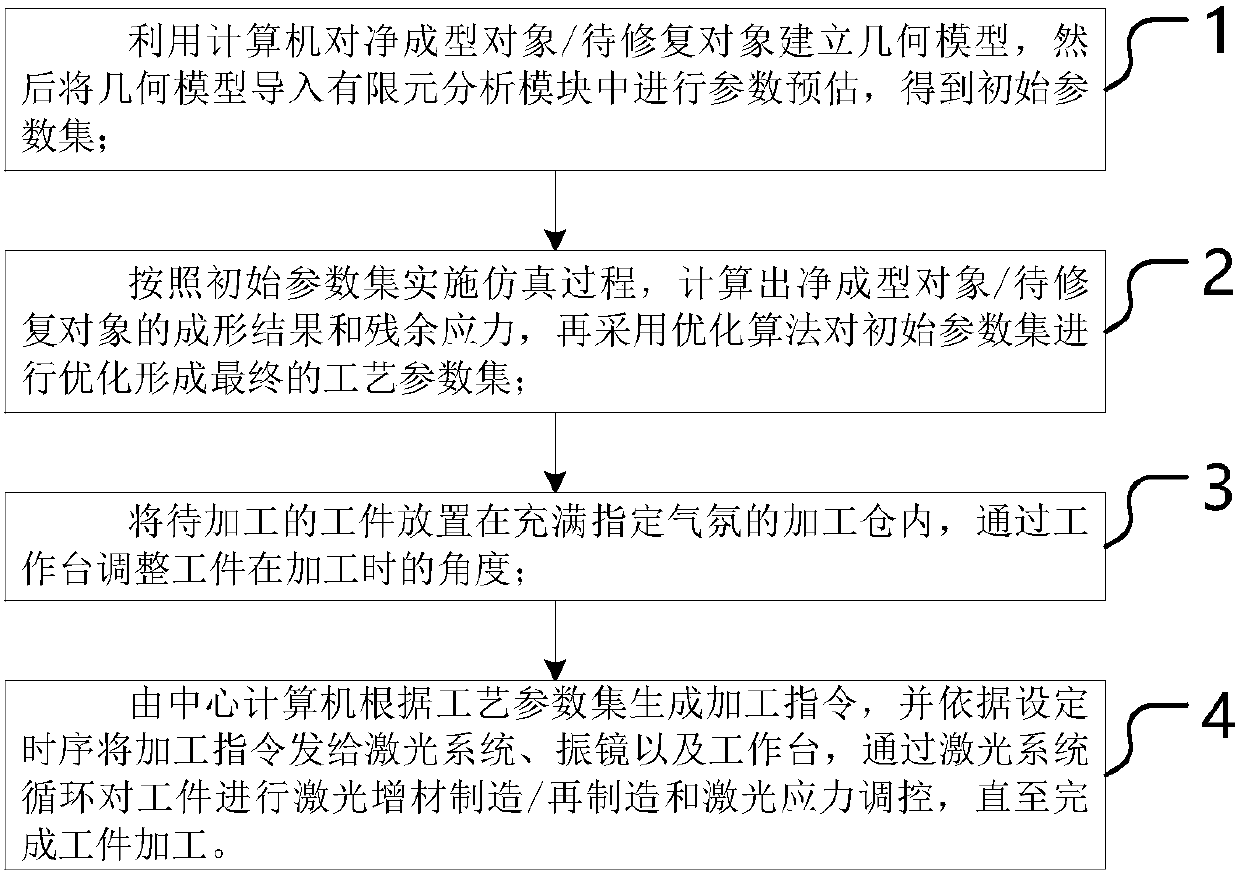

[0025] Such as figure 1 As shown, a laser control device for adjusting stress during laser additive manufacturing or remanufacturing according to an embodiment of the present invention generally includes a processing chamber 1 , a laser system 2 and a vibrating mirror 3 .

[0026] The processing chamber 1 is used to provide a working space for workpiece processing, and is a box-like structure that is sealed and filled with ambient atmosphere.

[0027] The laser system 2 performs laser additive manufacturing / remanufacturing on the workpiece 4 placed in the processing chamber 1 according to the pre-simulated process parameter set, and performs laser additive manufacturing / remanufacturing on the processing point of the current workpiece while laser additive manufacturing / remanufacturing Laser stress regulation to eliminate the stress generated at the current processing point during laser additive manufacturing / remanufacturing. In the specific work, each processing point uses las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com