Production method of high-magnetic-induction-orientation silicon steel

A technology of high magnetic induction orientation and production method, applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problems of waste of resources, high cost, cumbersome process, etc., to save resources, simplify processes, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

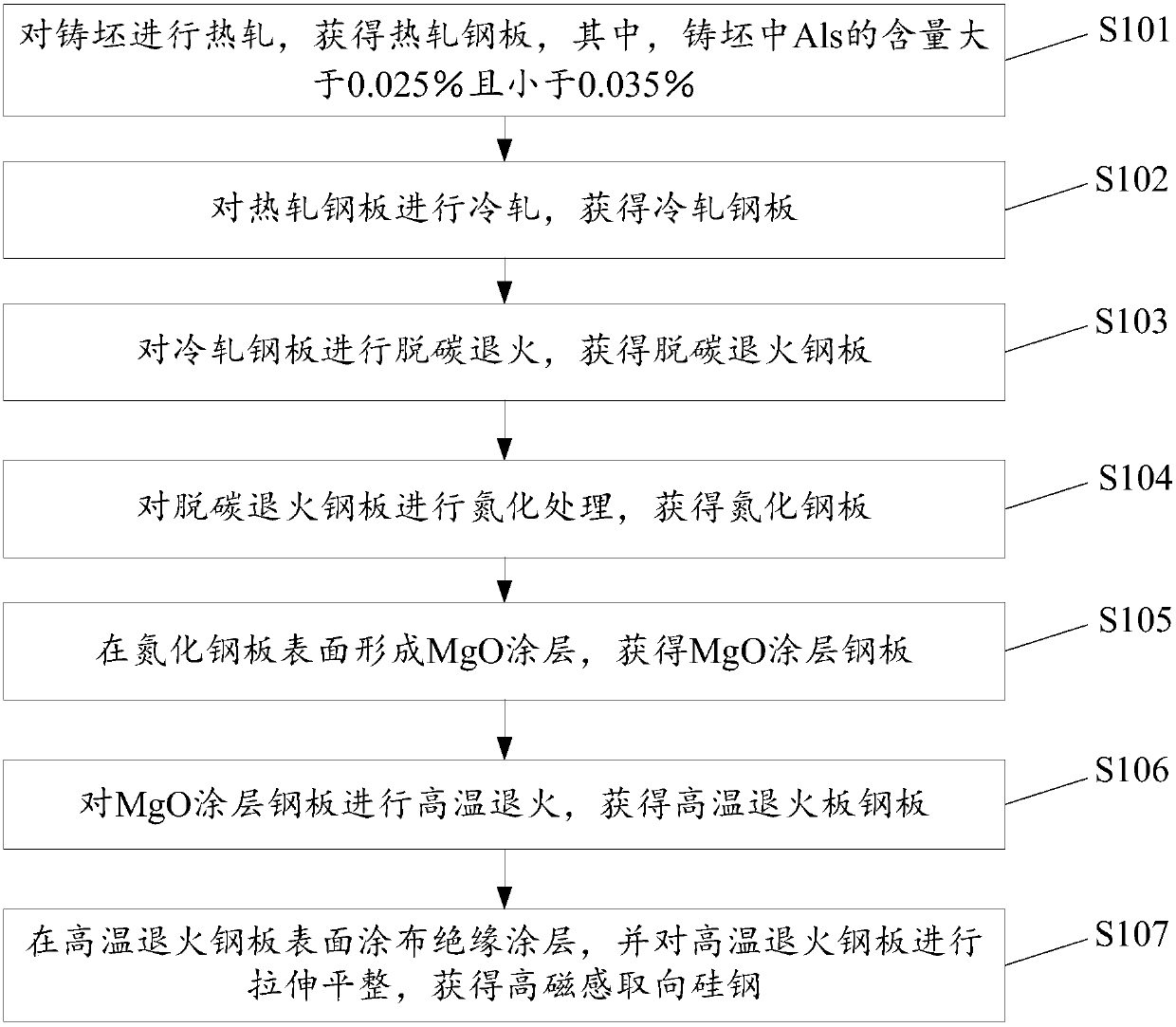

[0036] Such as figure 1 As shown, the present invention provides a kind of production method of high magnetic induction grain-oriented silicon steel, comprising:

[0037] Step S101: Hot rolling the cast slab to obtain a hot-rolled steel plate, wherein the Als content in the cast slab is greater than 0.025% and less than 0.035%.

[0038] In the specific implementation process, before step S101, it also includes: using a converter to smelt molten iron, and undergoing secondary refining and continuous casting to obtain a slab. Wherein, the composition of the slab includes: 0.03%<C≤0.08%, 2.6%≤Si≤4%, 0.07%≤Mn≤0.2%, 0.005%≤S≤0.01%, 0.025%≤Als≤0.035%, 0.004%≤N≤0.01%, 0.01%≤Sn≤0.05%, the rest is Fe and unavoidable impurities, expressed in weight percent. Among them, C-carbon, Si-silicon, Mn-manganese, S-sulfur, Als-acid-soluble aluminum, N-nitrogen, Sn-tin, Fe-iron.

[0039] In this embodiment, compared with the prior art, the content of Als is increased, thereby compensating for ...

example 1~3

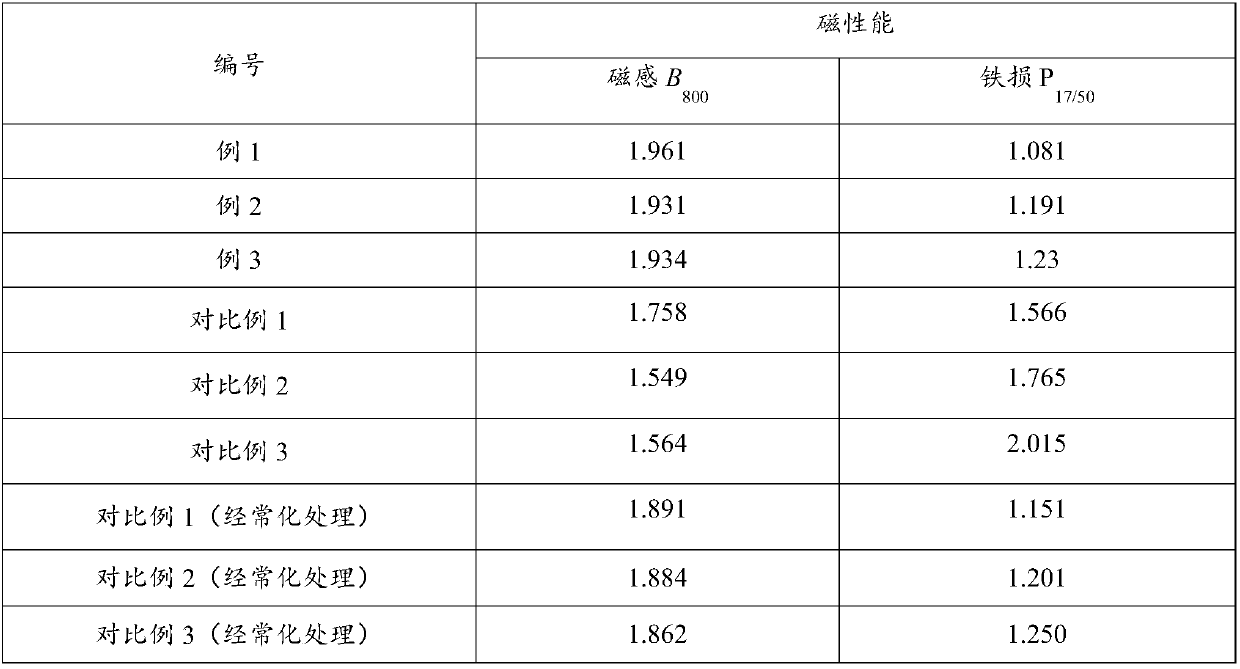

[0064] Example 1~3 : produce high magnetic induction oriented silicon steel according to the production method of high magnetic induction oriented silicon steel provided by the present invention. Hot rolling is carried out on a 1580mm hot rolling line, the cast slab is heated to 1150°C, the thickness of the hot-rolled plate is 2.3mm, and the coiling temperature is 550°C; once cold rolled to a finished product thickness of 0.30mm; at a dew point of 70°C N 2 +H 2 Carry out decarburization annealing at 850°C in the atmosphere, and the decarburization annealing time is 150 seconds; then carry out nitriding treatment at 750°C; after coating MgO spacer, perform high-temperature annealing at 1150°C to 1250°C in a ring furnace.

[0065] The ingredients of Examples 1-3 and Comparative Examples 1-3 are shown in Table 1, the main difference being the Als content; the product properties are shown in Table 2.

[0066] The comparative example carried out the same production process as th...

example 4

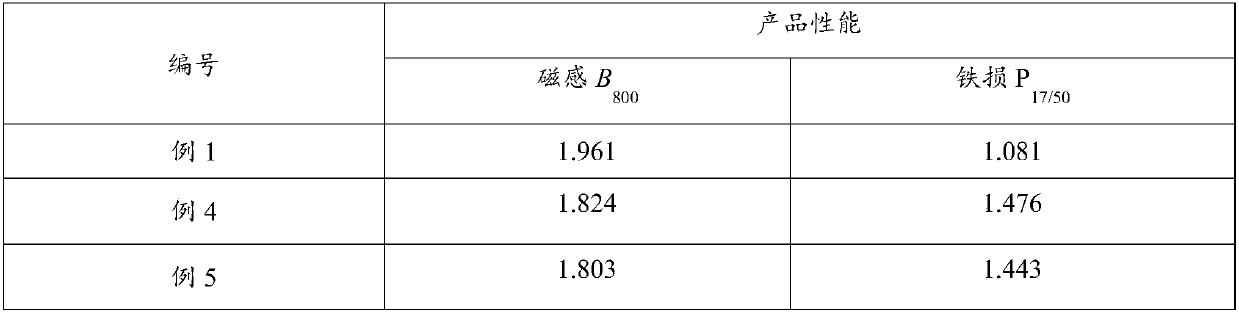

[0071] Example 4 : produce high magnetic induction oriented silicon steel according to the production method of high magnetic induction oriented silicon steel provided by the present invention. Hot rolling is carried out on a 1580mm hot rolling line, the cast slab is heated to 1150°C, the thickness of the hot-rolled plate is 2.3mm, and the coiling temperature is 550°C; once cold rolled to a finished product thickness of 0.30mm; at a dew point of 70°C N 2 +H 2 Carry out decarburization annealing at 830°C in the atmosphere, and the decarburization annealing time is 150 seconds; then carry out nitriding treatment at 750°C; after coating MgO spacer, perform high-temperature annealing at 1150°C-1250°C in a ring furnace. The composition of Example 4 is shown in Table 3, and the main difference from Example 1 is to change the decarburization annealing temperature; the product performance is shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com